Main-sub pot-type combined container for liquid nitrogen

A technology of mother-child tank and liquid nitrogen, which is applied to pressure vessels, container filling methods, container discharge methods, etc., can solve the problems of one-time safety valve hysteresis bursting disc, it is difficult to meet safety, etc., and achieve low manufacturing and installation costs. , high reliability, the effect of reducing emission loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

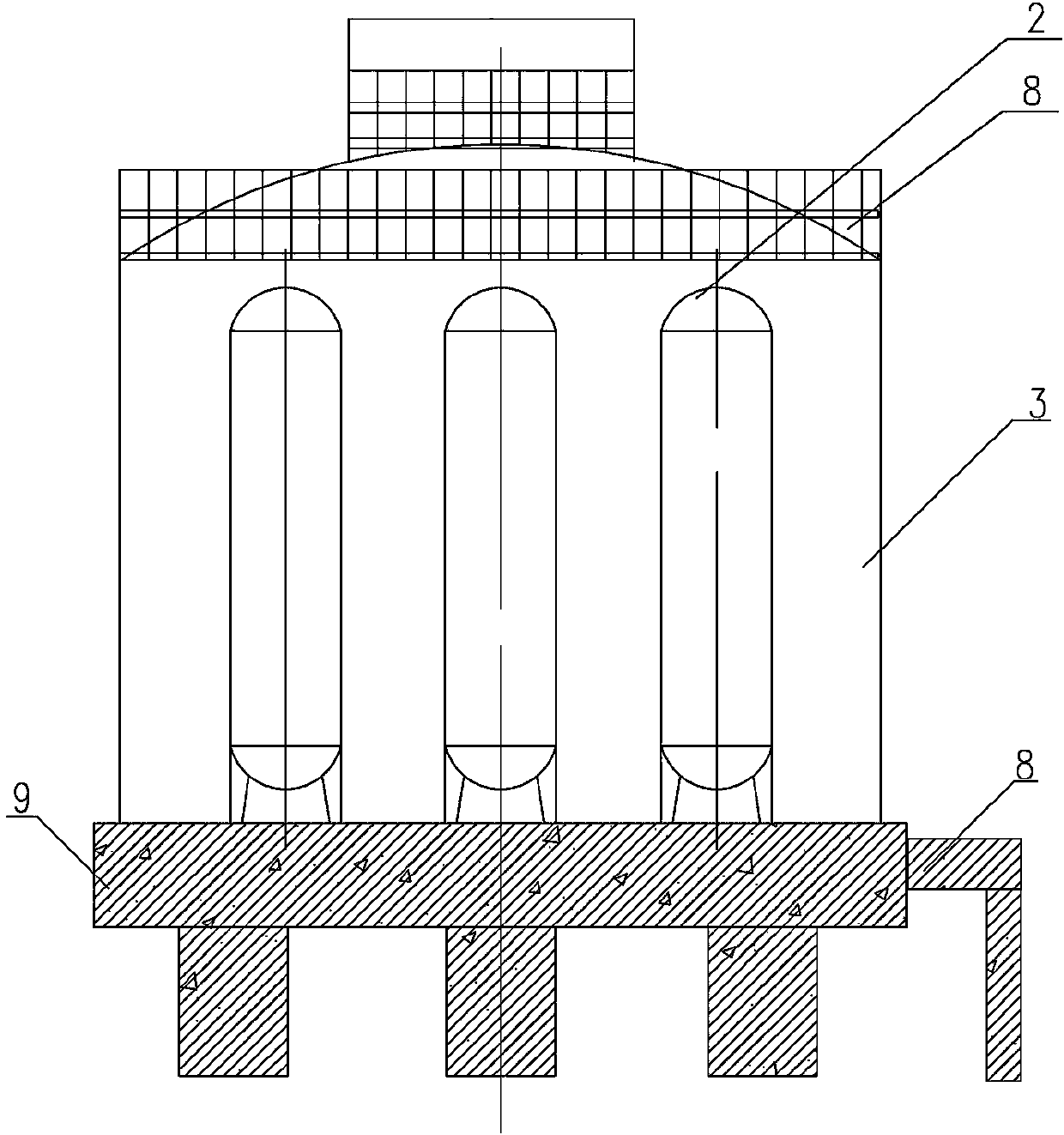

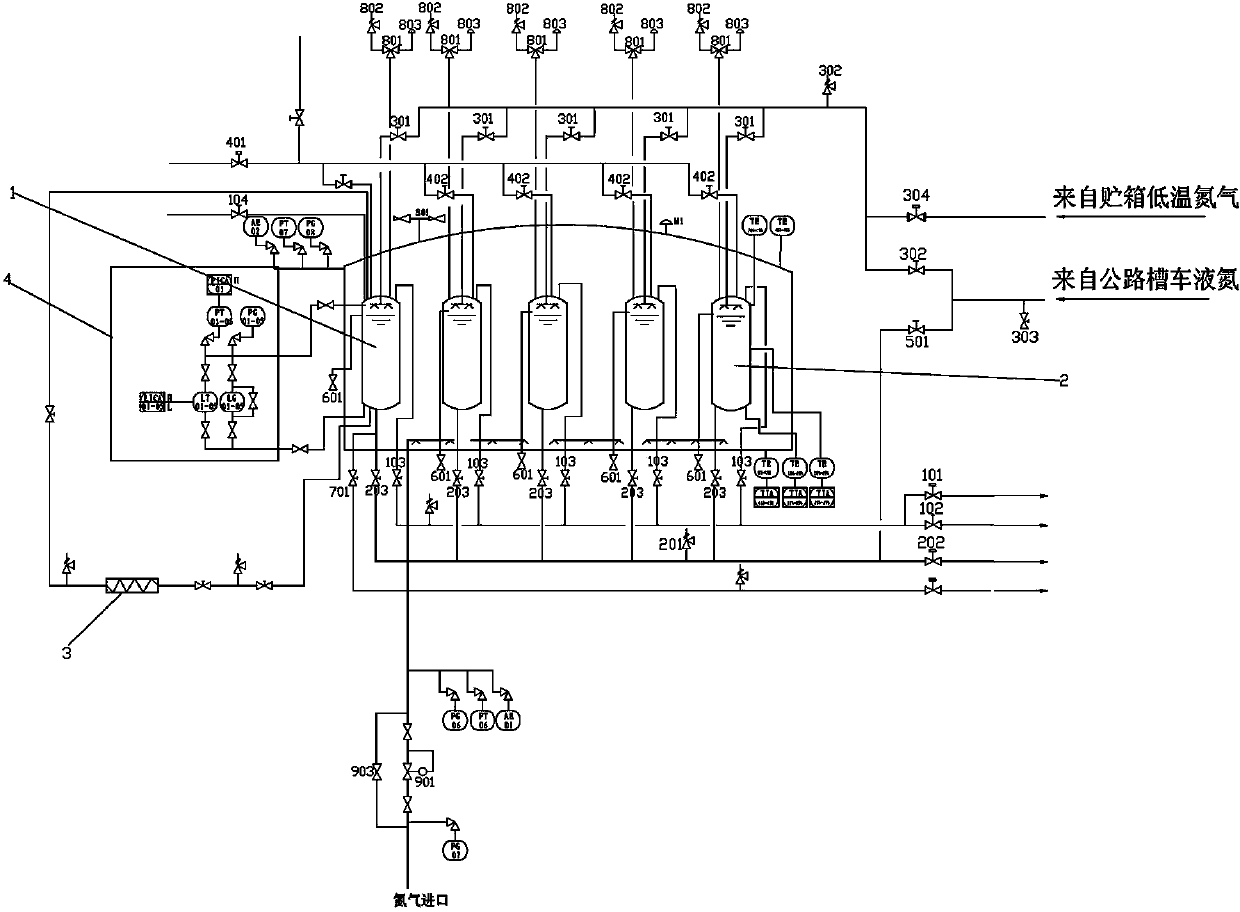

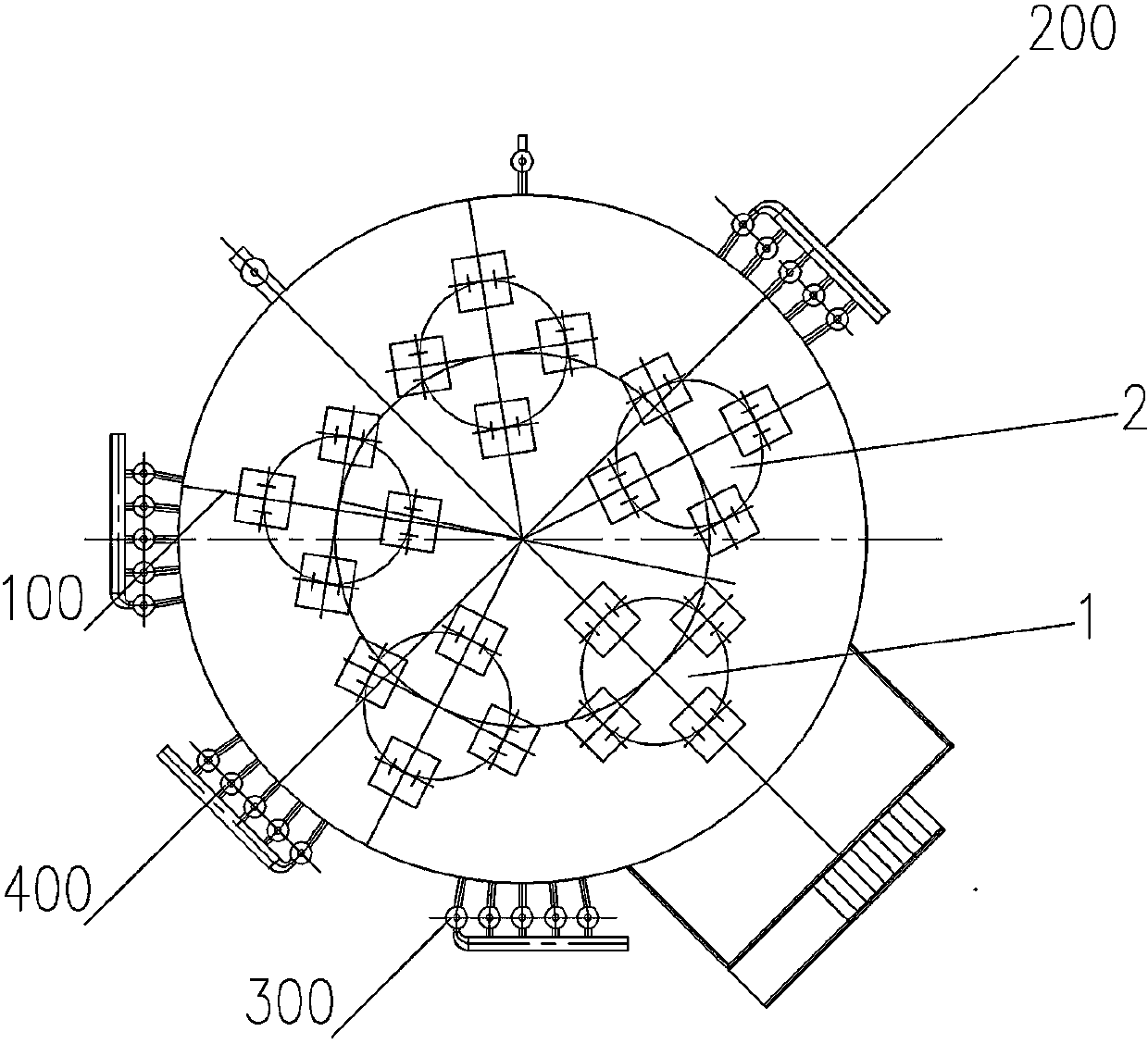

[0035] Such as Figure 1-3 As shown, the combined container of the son-mother tank type of the present invention includes a sub-tank, a piping system, an interlayer, a mother tank 3 , a measurement and control system, safety accessories and an external operating platform 8 . Paint spraying is carried out on the outside of the liquid nitrogen combination container, and is installed on the foundation platform 9. The five sub-tanks are respectively one self-pressurized sub-tank 1 and four common sub-tanks 2, the five sub-tanks are arranged in a concentric regular polygon, and the piping system is arranged in the area between the five sub-tanks and the center of the mother tank. The pipelines in the mother tank are installed in clusters, and after leaving the mother tank, they are grouped together to form an up-transfer valve group 300, a booster valve group 400, a discharge valve group 100 and a filling valve group 200.

[0036] The pipeline system includes a filling pipeline, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com