Production mold for adhesive tape for steel wire adhesive force test sample and method

An adhesive force and adhesive strip technology, applied in the field of using the mold to make the required adhesive strips, can solve the problems of time-consuming and labor-intensive, low adhesive strip production efficiency, etc., and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

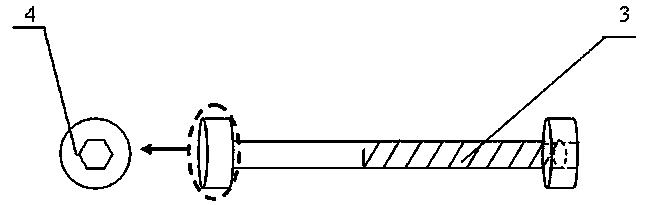

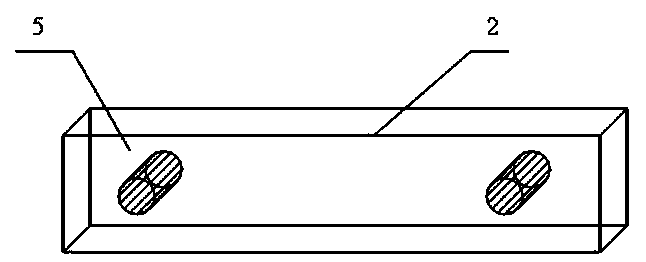

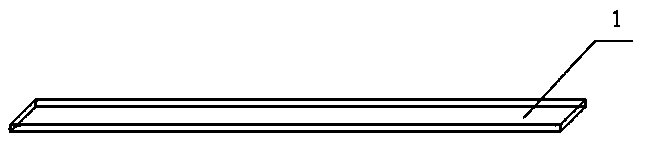

[0028] combine Figure 1~4 Illustrate this embodiment, a kind of mold that is used for the production mold of the rubber strip required for steel wire adhesion test sample, comprises cutting knife 1, connecting rod 3, partition board 2, and described partition board 2 is several, and all partition boards 2 All are fixed on the connecting rod 3, a cutting knife 1 is fixed between any two adjacent partitions 2, and the thickness of the partition 2 between the two adjacent cutting knives 1 is equal to the thickness of the required rubber strip. width.

[0029] The cutting knife 1 is clamped and fixed by two partitions 2 .

[0030] The connecting rod 3 is a half-threaded rod with nuts 4 at both ends, and all partitions 2 are installed between the nuts 4 at both ends of the connecting rod 3 .

[0031] The cutting knife 1 is made of steel, and is fixed by the pressure between the partitions 2 . The separator 2 is made of steel. The connecting rod 3 is made of steel. The steel m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com