Offline Planning Method of Feed Rate in NC Machining Constrained by Jerk

A technology of feed rate and curve, applied in the field of off-line planning of CNC machining feed rate, to achieve the effect of ensuring quality and accuracy and avoiding repeated interpolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and technical solutions.

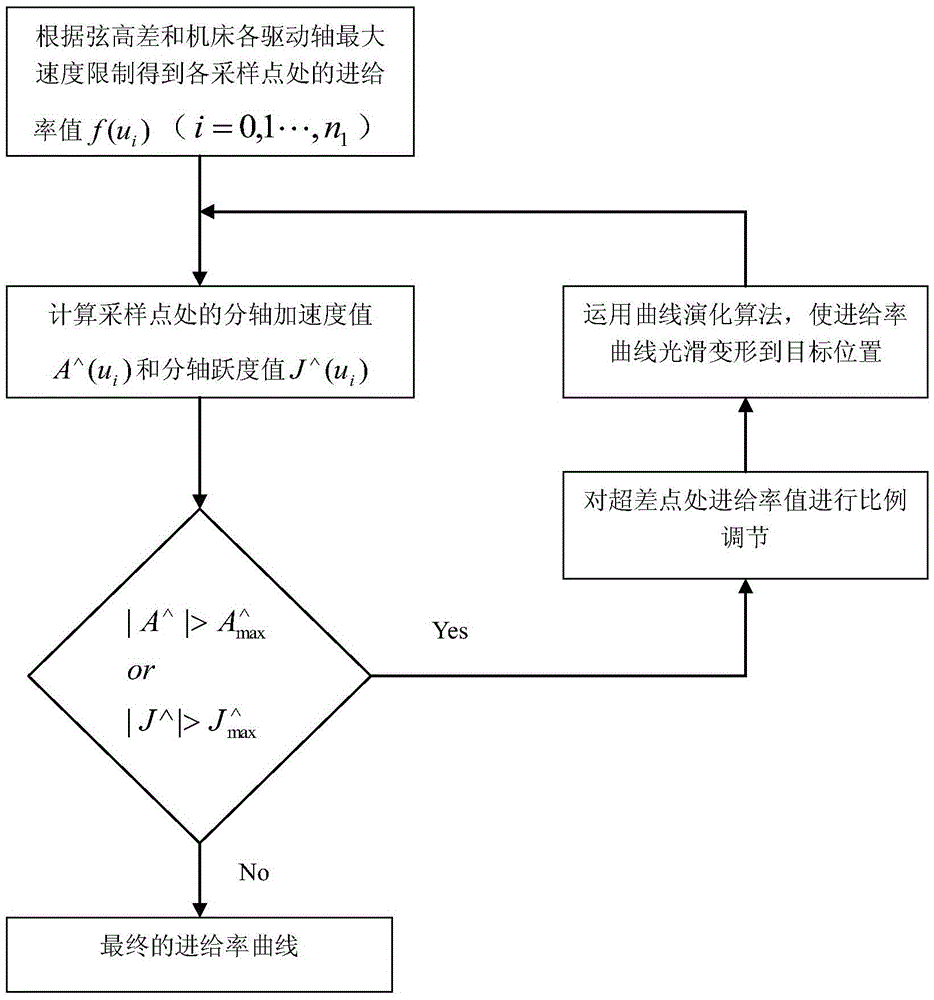

[0021] The flow chart of the off-line planning method of the NC machining feed rate of the jerk constraint proposed by the present invention is as follows: figure 1 shown. According to the chord height difference and the speed limit of each driving axis of the machine tool, the initial feed rate value of each sampling point is obtained. Calculate the sub-axis acceleration value and sub-axis Jerk value at each sampling point, and compare with the set sub-axis acceleration limit value and sub-axis Jerk limit value to determine whether there is an out-of-poor point. If there is an over-difference point, the feed rate value at the over-difference point will be adjusted proportionally. After the proportional adjustment is completed, the curve evolution algorithm is used to smoothly deform the feed rate curve to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com