A kind of preparation method of bulge sample of layered electromagnetic thin film material

A thin-film material and electromagnetic technology, applied in the field of electromagnetic thin-film functional materials, can solve problems such as filling material components and formulas that cannot be satisfied, and achieve high sample preparation efficiency, high efficiency, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with specific embodiments.

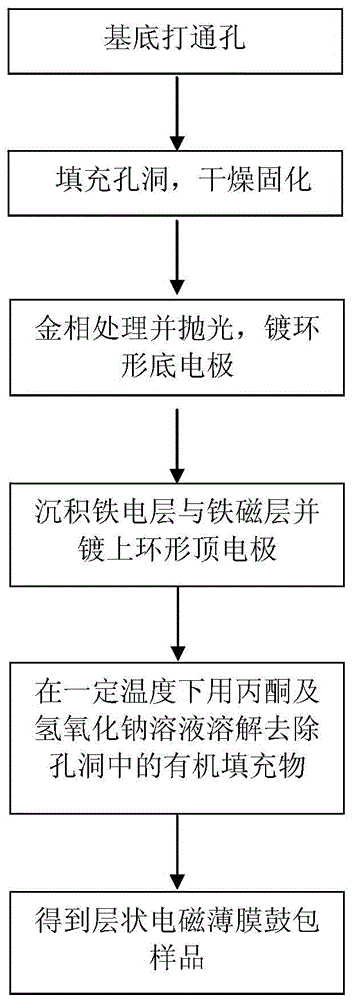

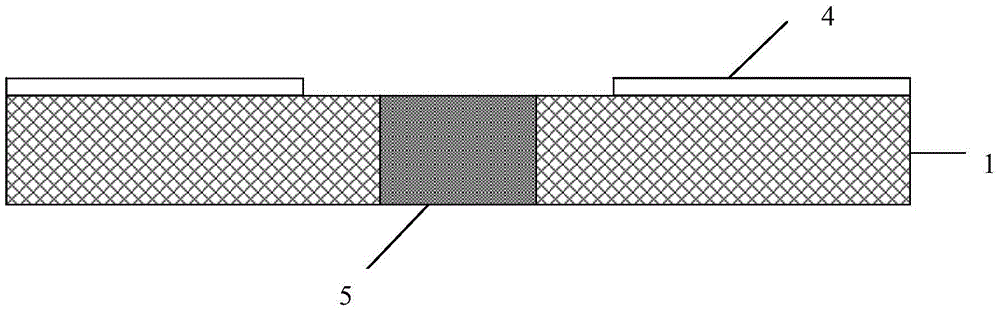

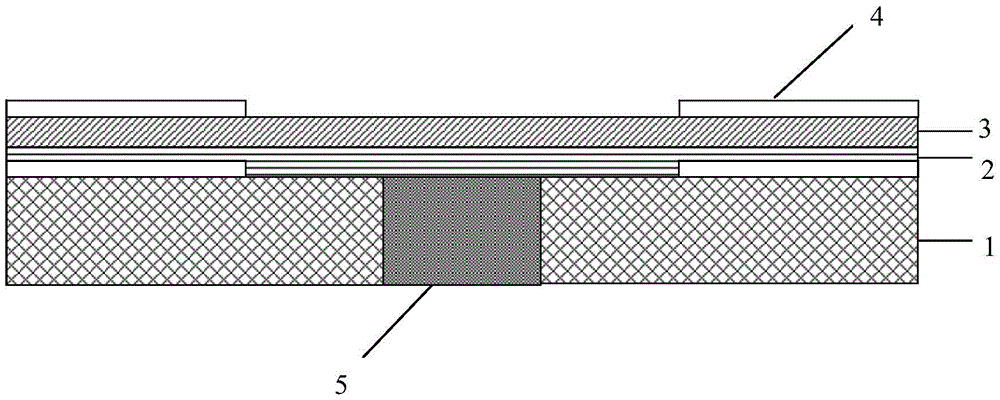

[0028] The technical scheme adopted by the present invention to solve the above-mentioned technical problems is as follows: firstly, a through hole with a specified diameter is drilled on the silicon dioxide substrate with a micro-drilling machine. Then put the substrate flat on a glass sheet, pour special filling material into the through hole, and gradually tamp it with tools until it is flush with the upper surface of the substrate. Then the lower surface of the substrate is metallographically treated and polished so that the filling material and the lower surface of the substrate are strictly in the same plane. Then another silicon wafer with a specific diameter is used to cover the filling material, and a platinum layer with a thickness of about 5 nanometers is deposited on its surface by magnetron sputtering method as the bottom electrode. Then remove the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com