Handle device

A technology for handles and conversion devices, which is applied in the direction of portable motorized devices, portable impact tools, electrical components, etc., can solve problems such as side effects and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

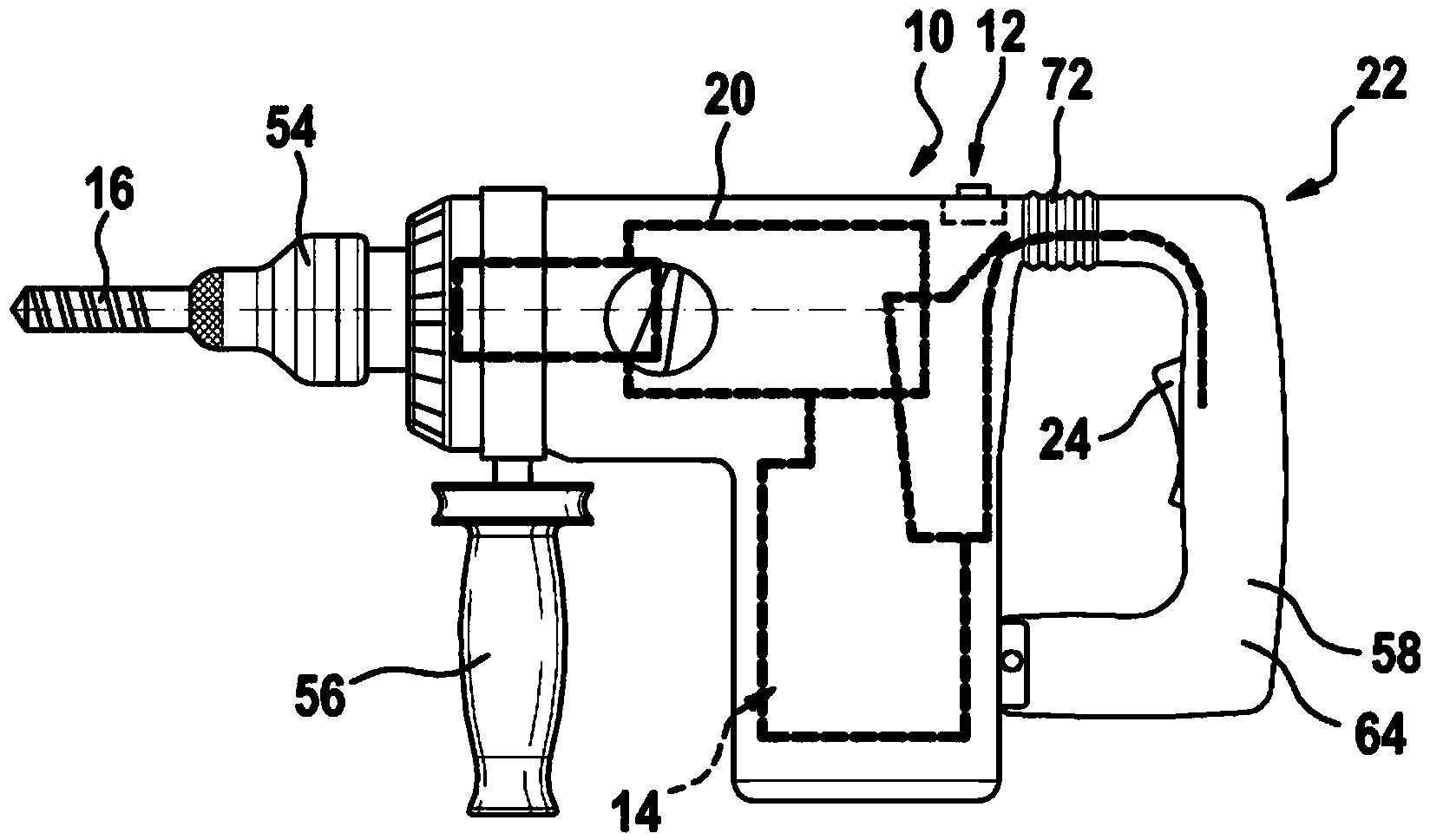

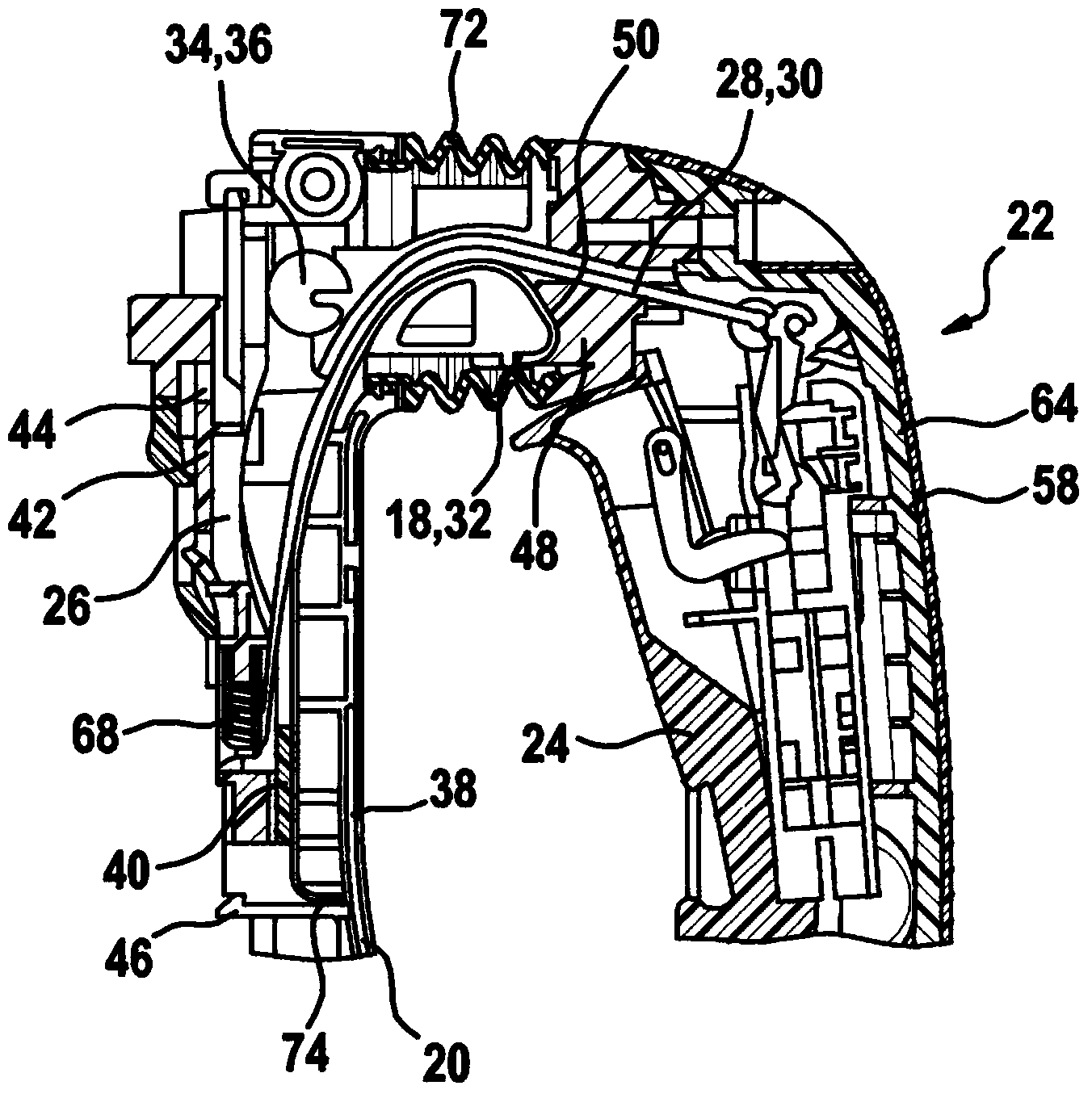

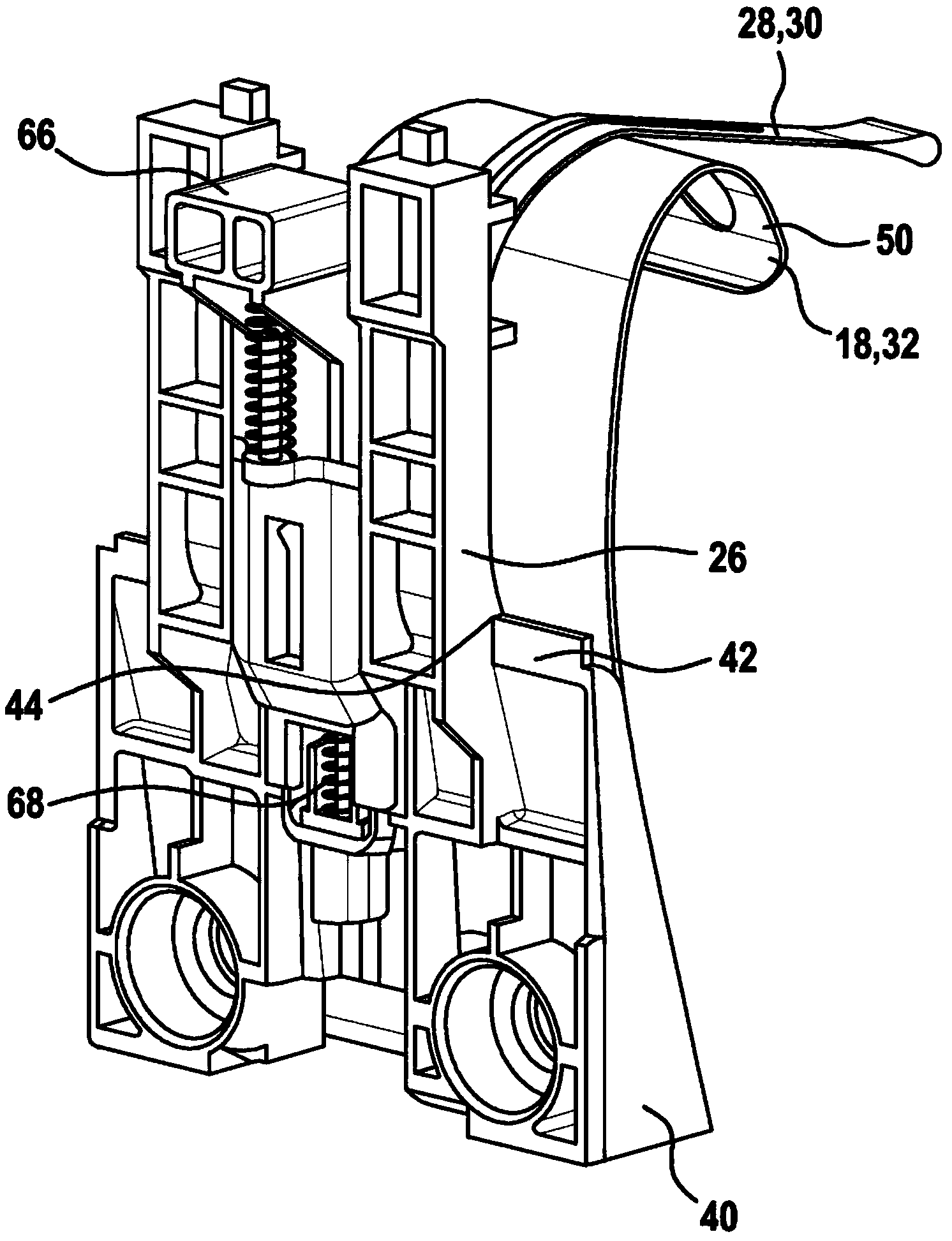

[0049]1 shows a schematic view of a hammer drill and / or chisel hammer as an example of a hand-held power tool 10 with a machine housing 20 , a tool holder movably arranged on the machine housing 20 The device 54 serves to exchangeably receive the plug-in tool 16 and the drive device 14 , which is accommodated in the machine housing 20 and has a drive unit and a transmission unit, for driving the plug-in tool 16 in different operating modes. In this case, the tool holder 54 is preferably arranged rotatably on the front side of the machine housing 20 . Furthermore, in the example according to FIG. 1 , a handle arrangement is provided on the side of the machine housing 20 opposite the end side of the machine housing 20 . In the present example, the handle arrangement includes a switch operator 24 for putting the drill hammer and / or chisel hammer into operation. The switch actuator 24 can be switched between two switching positions both monostable and bistable. Furthermore, an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com