Extruder screw, extruder, and method for producing an extruder screw

A technology of machine screw and extrusion shaft, which is applied in the field of twin-screw extruders, can solve the problems of torque limitation and damage to the extrusion section, and achieve the effect of high wear resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

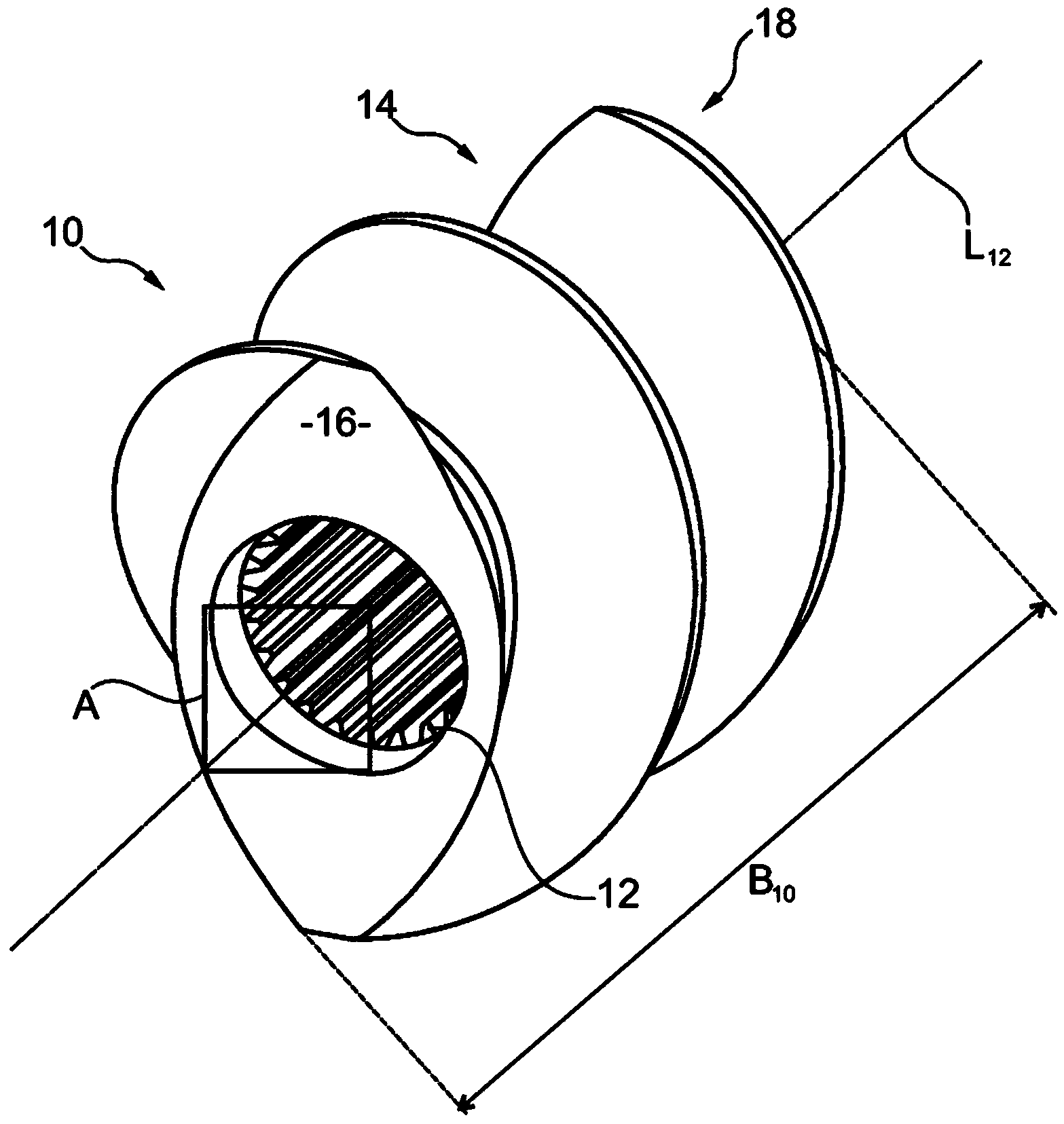

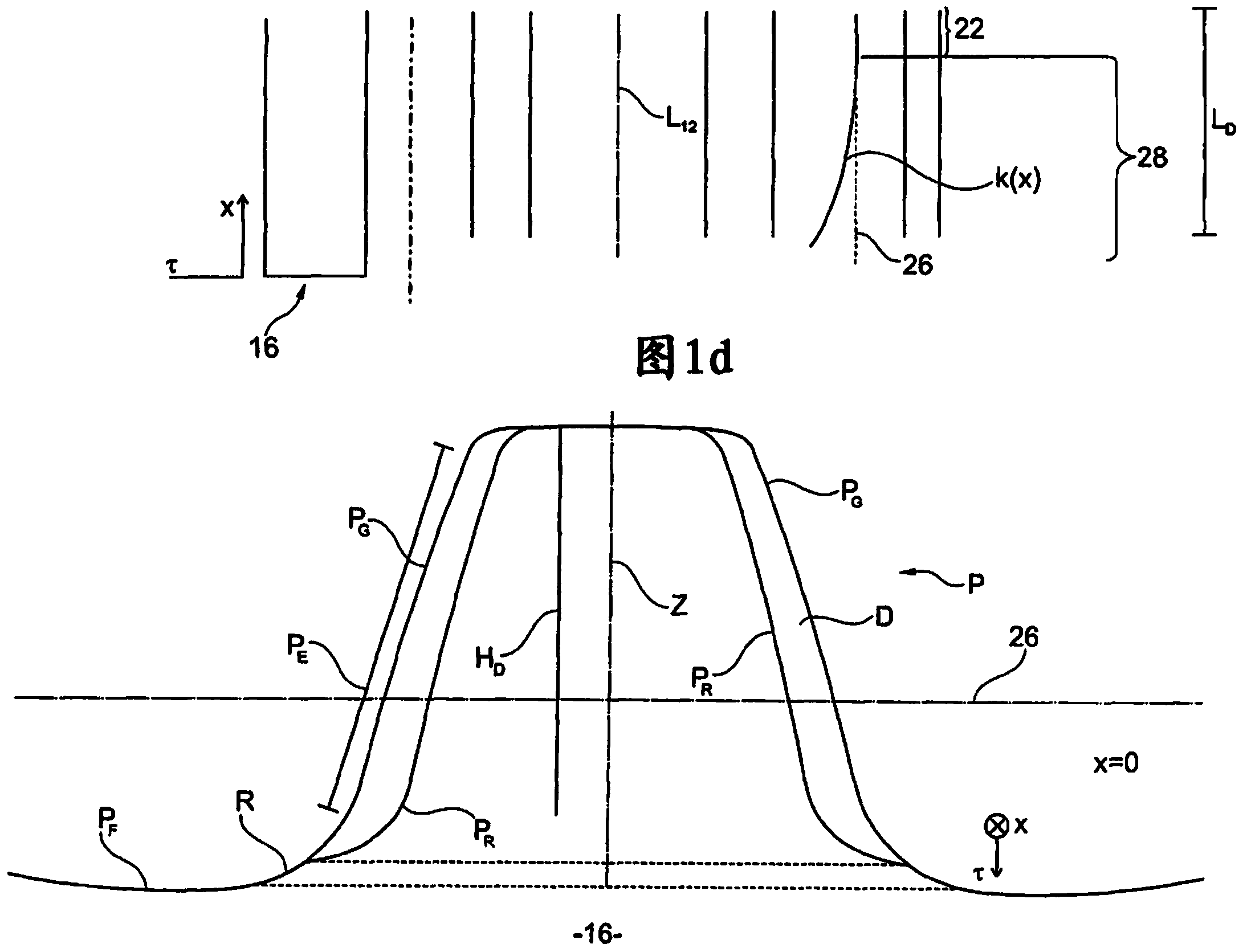

[0032] FIG. 1 shows an extrusion segment 10 according to the invention, which has an internal toothing 12 , by means of which it can be fitted in a rotationally fixed manner on a complementary external toothing of a mandrel of an extrusion shaft. The internal toothing 12 has a meshing profile P in which Figure 1c The mating profile is shown in .

[0033] Figure 1a It is shown that the extruded section 10 comprises an outer helix 14 . Or, as an alternative, the extrusion section 10 can have, for example, a conveying structure, a shaping structure or a mixing structure.

[0034] The extruded section 10 has a first end side 16 and a second end side 18 opposite the first end side 16 , which runs parallel to the first end side 16 . The internal toothing 12 has a toothed longitudinal axis L 12 , the extruded section 10 has a width B along the toothed longitudinal axis 10 .

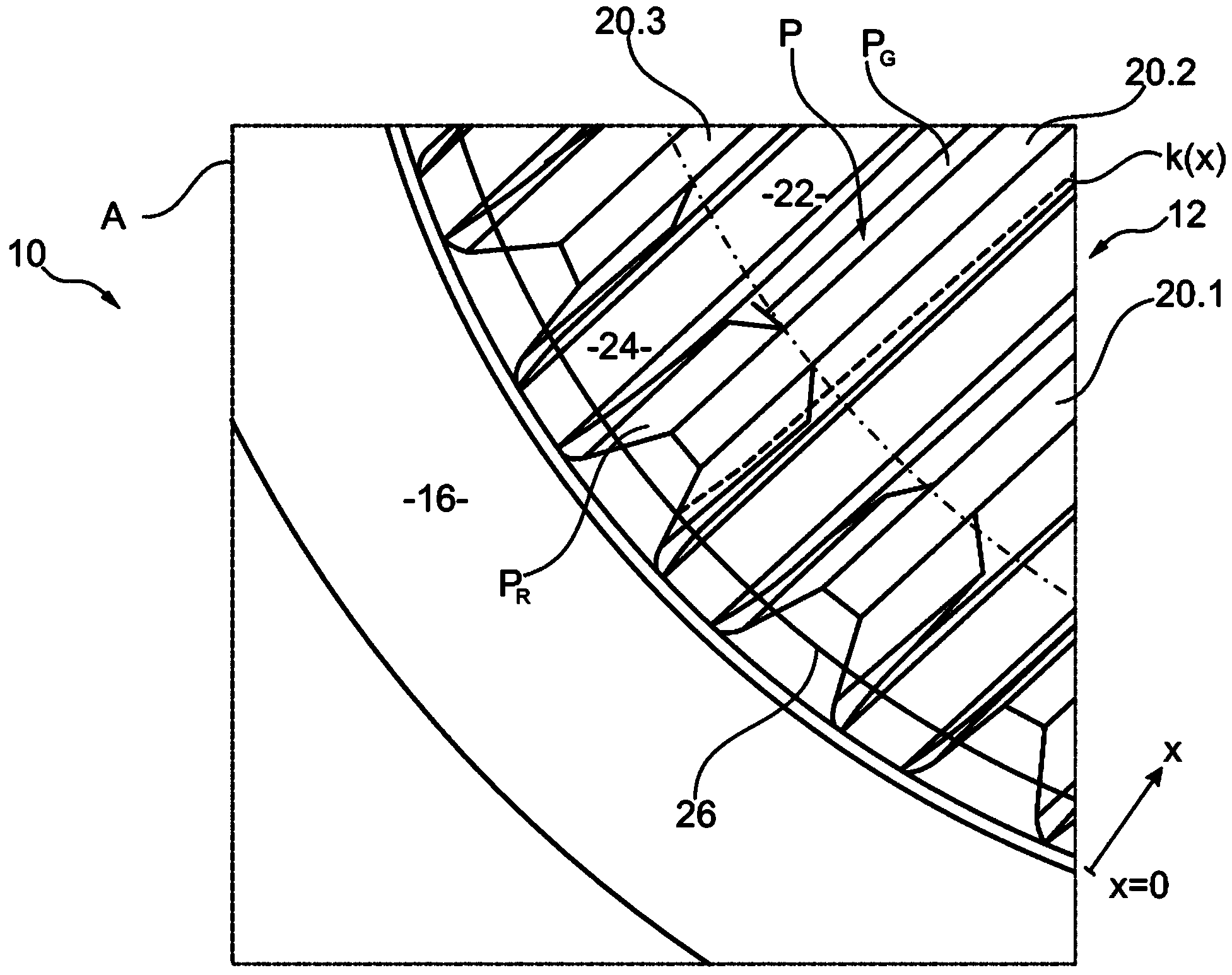

[0035] Figure 1b Shown is Figure 1a Local segment A in . It can be seen that the internal toothing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com