Steel oil well pipe having excellent sulfide stress cracking resistance

A technology for steel pipes and oil wells, applied in the direction of improvement of process efficiency, furnace type, furnace, etc., to achieve the effect of excellent SSC resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

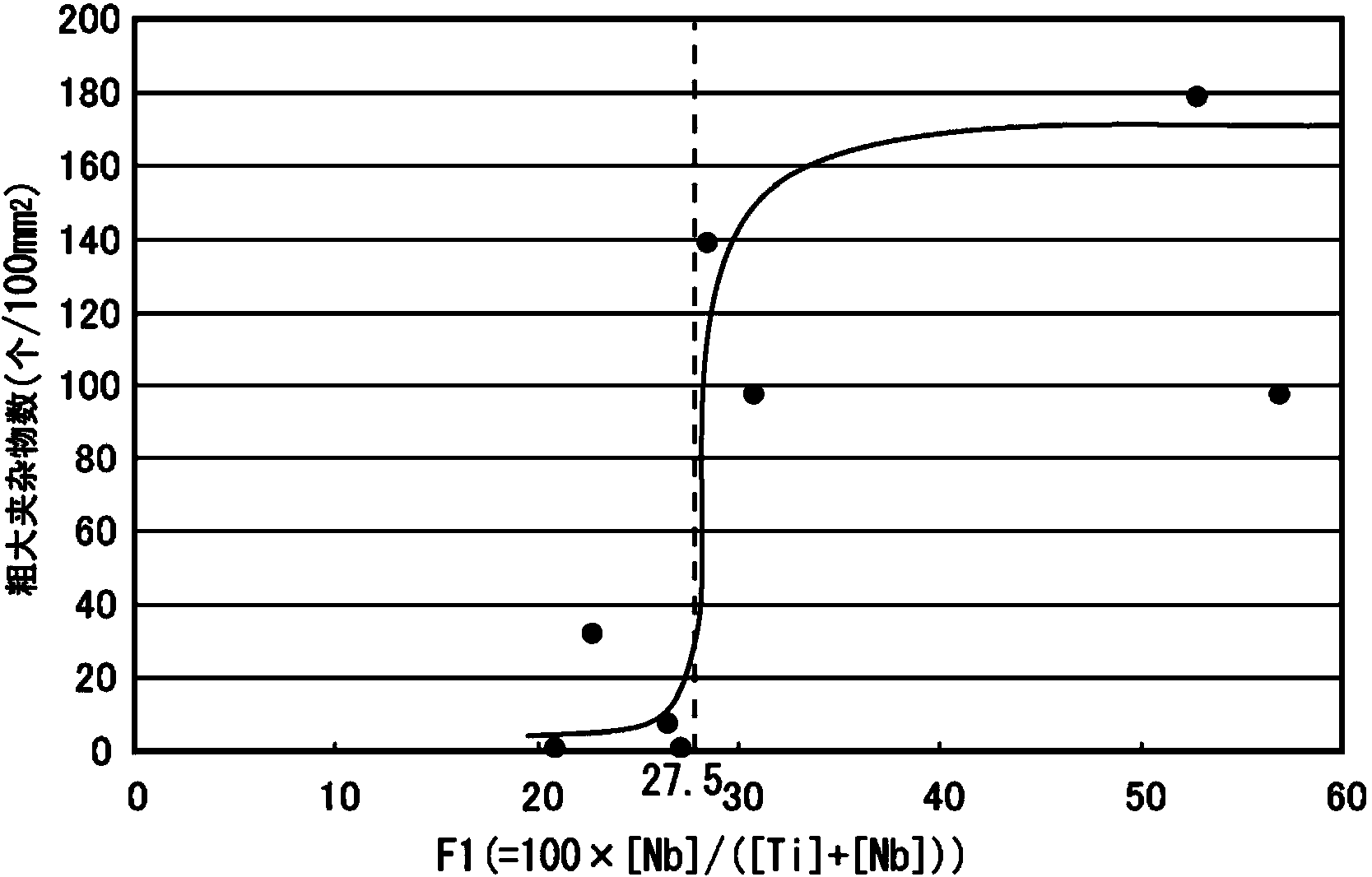

[0128] Steel pipes for oil wells with various chemical compositions are manufactured under various manufacturing conditions. The SSC resistance of the produced steel pipe for oil well was evaluated.

[0129] [Manufacturing method of steel pipe for oil well]

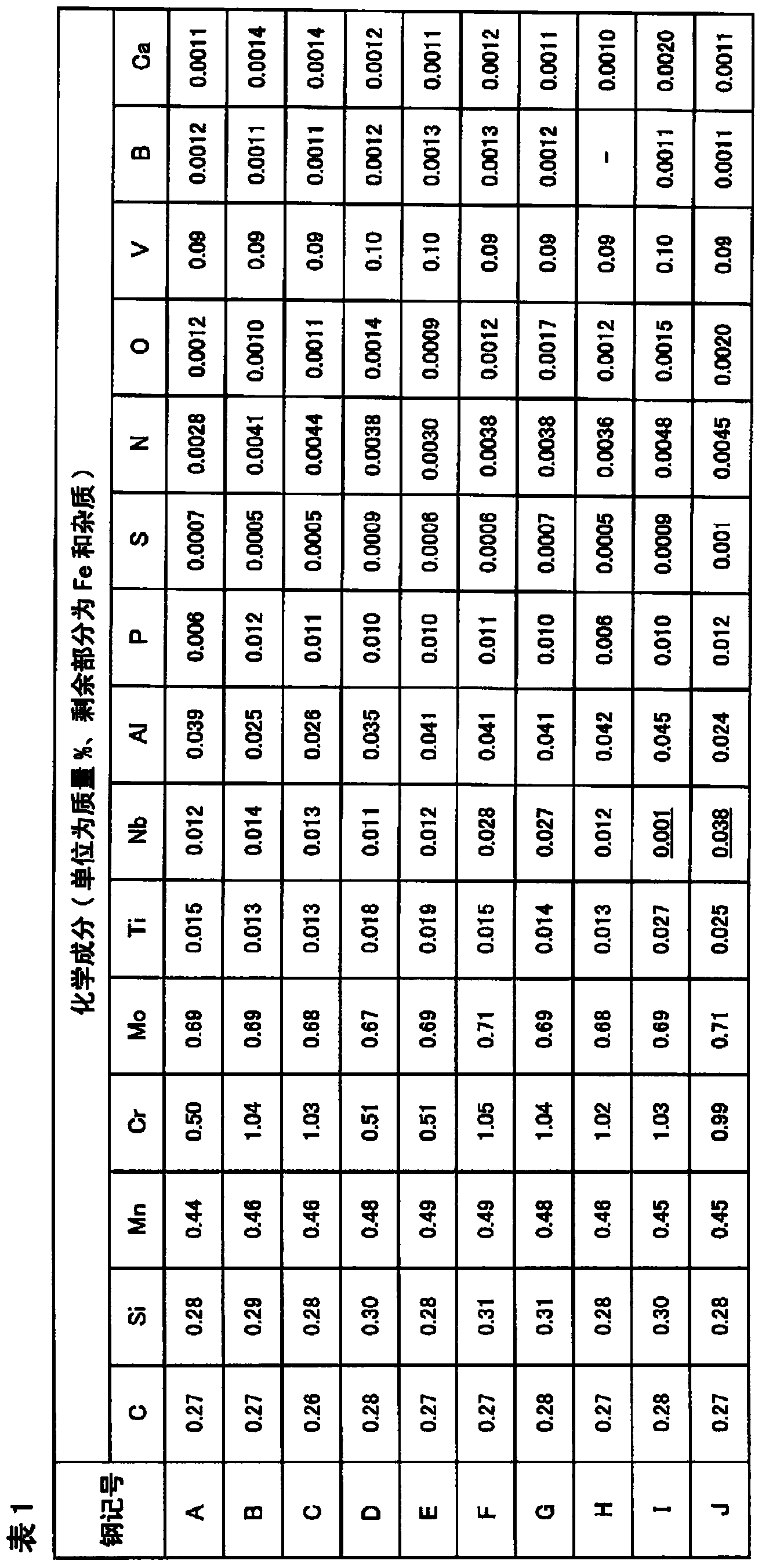

[0130] Molten steels of steels A to J having the chemical compositions shown in Table 1 were produced.

[0131]

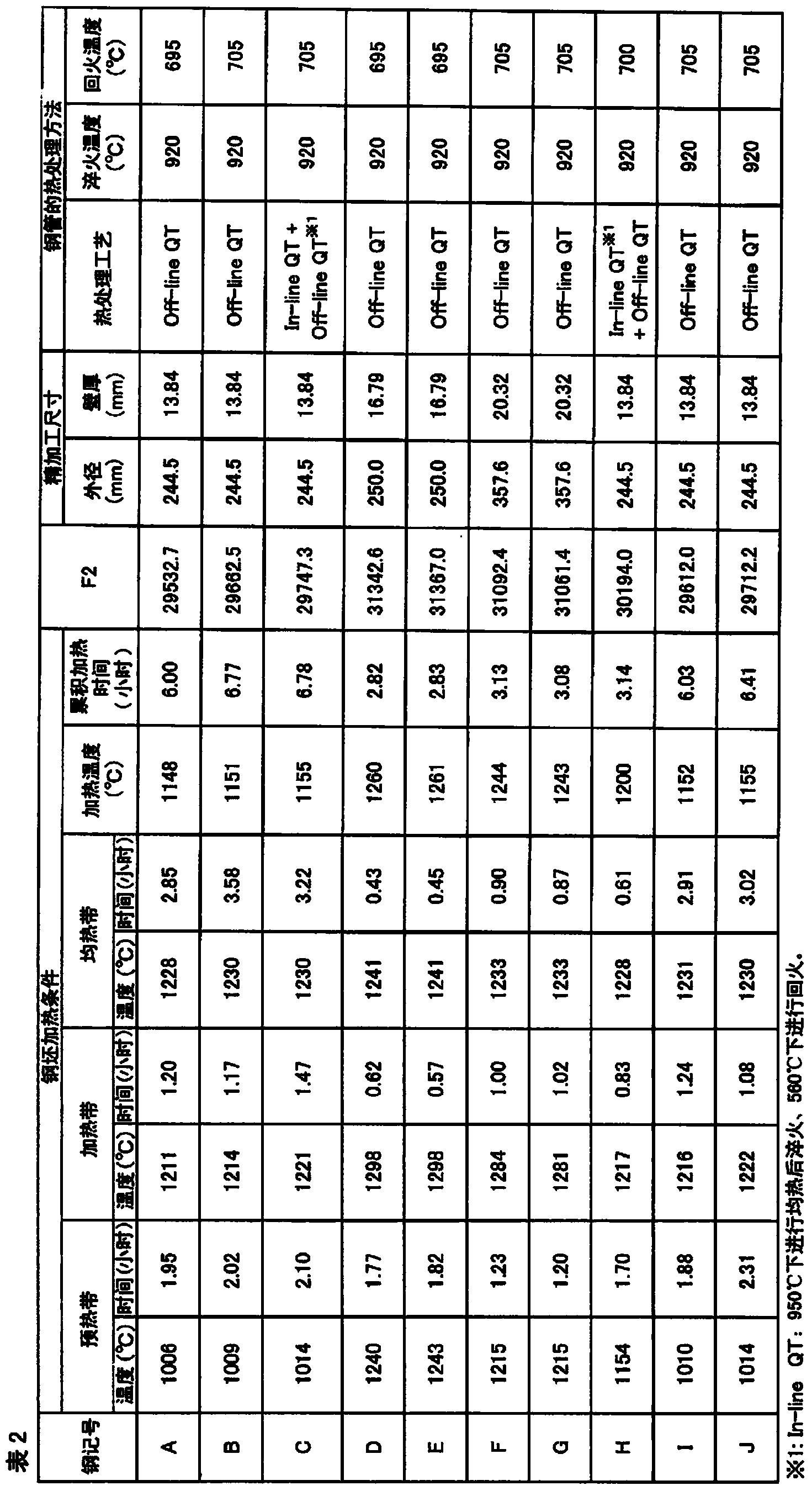

[0132] A round billet with a diameter of 310 mm was produced by a continuous casting method using molten steel (230 tons) of steels A to J. The round billets were heated in a heating furnace under the billet heating conditions shown in Table 2. The heated round steel billet is pierced and rolled according to the Mannesmann method to manufacture a tube billet. The blank pipe was quenched at the quenching temperature shown in Table 2, and tempered at the tempering temperature shown in Table 2 to manufacture steel pipes for oil wells. Adjust the quenching and tempering conditions so that the yield strength...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap