Complete-coverage laser lattice structure and method based on thermal burn weeding

A laser dot matrix, full coverage technology, applied in laser devices, weed eradication equipment, applications, etc., can solve problems such as unevenness, clustering, random distribution of weeds, etc., to achieve strong practicability and simple structural design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

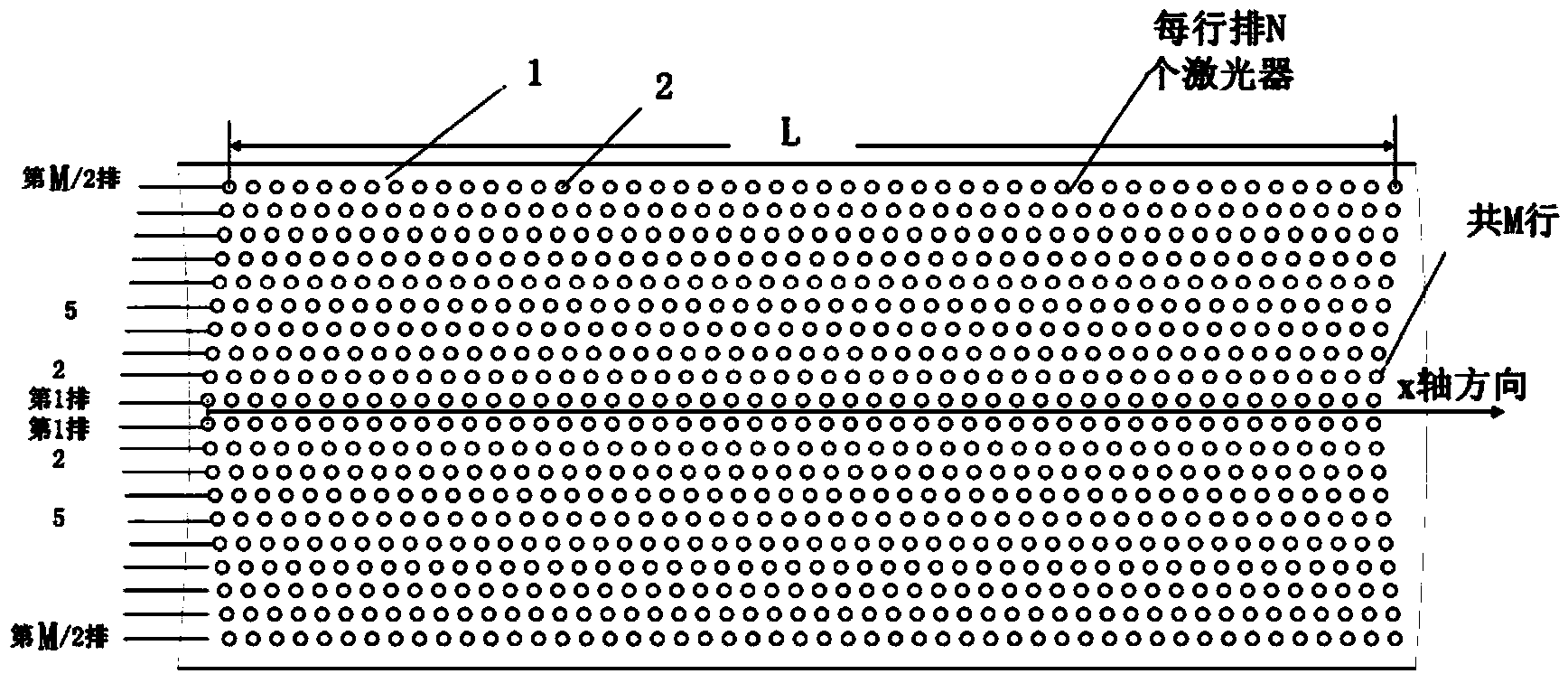

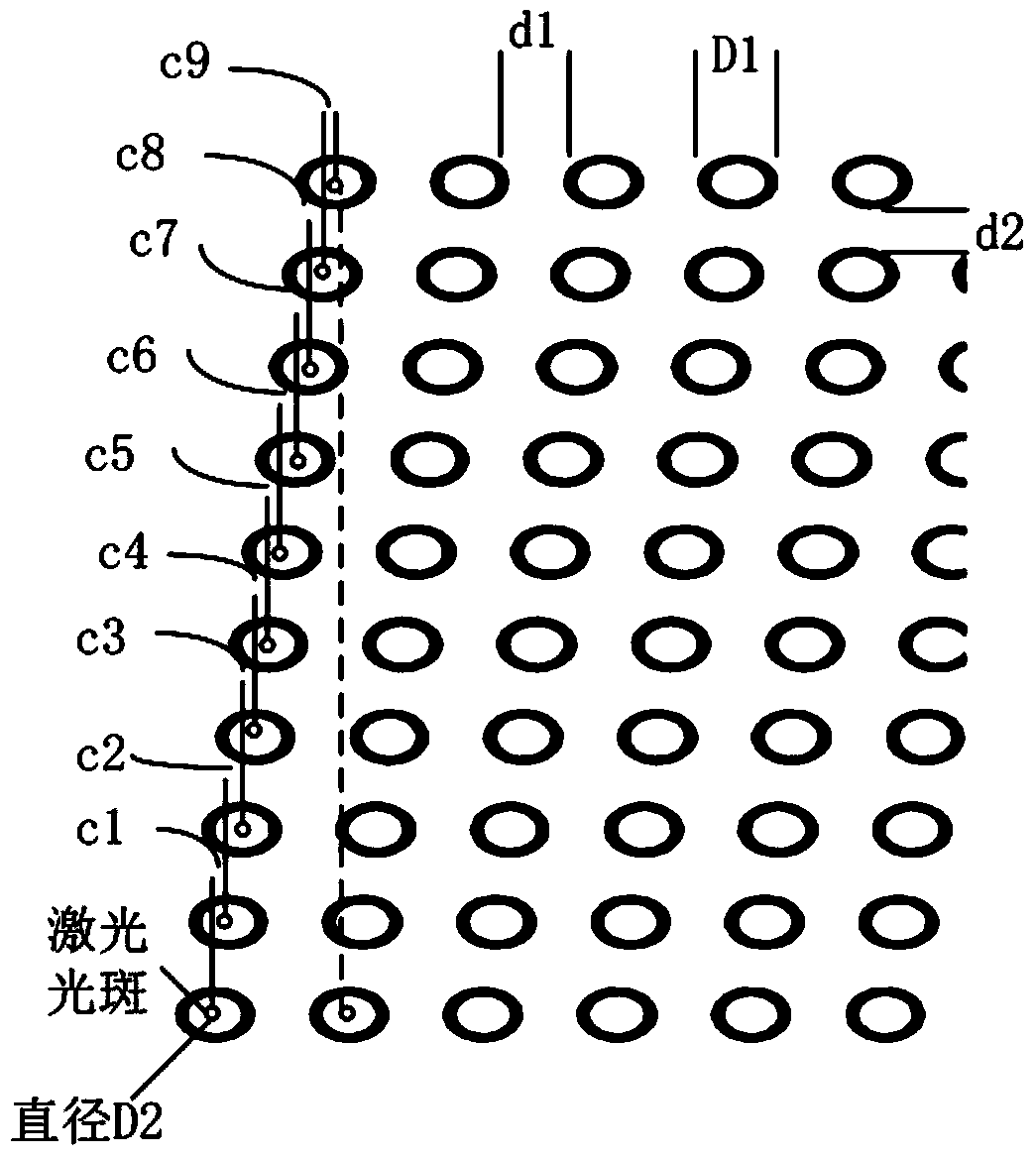

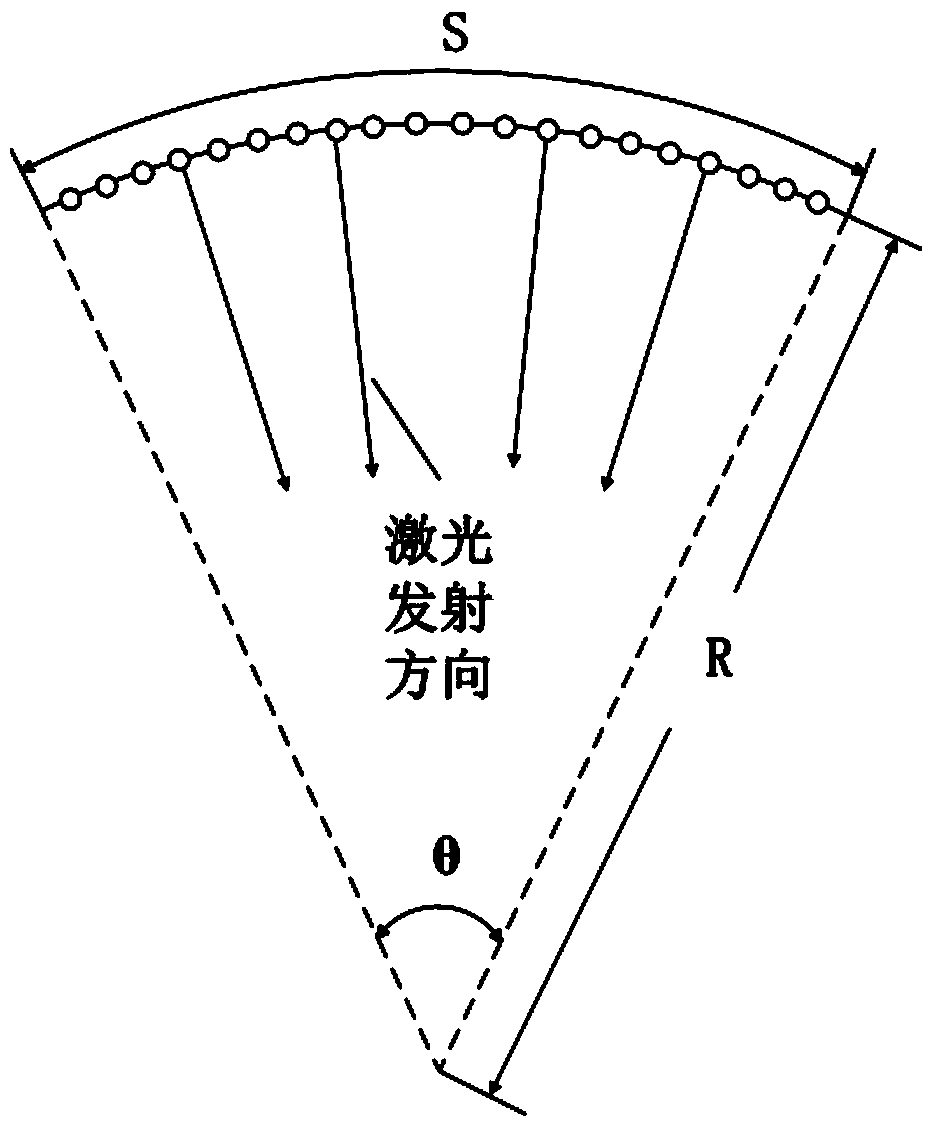

[0018] Such as figure 1 As shown, a full-coverage laser lattice structure based on heat injury and weeding is characterized in that the fixed frame 1 is a cylindrical surface, and N holes are arranged in each row on the fixed frame 1, and M rows are arranged in total. The diameter of the hole is D1, the distance between the holes in the same row is d1, and the distance between the holes in the adjacent row is d2, ensuring that d1+D1=M·D2 (this relationship can be satisfied by changing the value of d1). The axial length of the cylindrical surface L=(M-1)·(d1+D1), the arc length S>M·D1+(M-1)·d2, the diameter of the laser used is equal to the diameter of the hole, and the laser emits a spot at a distance R The diameter is D2. The row direction of the fixed frame 1 is set as the x-axis direction, and the laser dot matrix arranged on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com