Funnel suction nozzle type dust generator

A dust generator and dust technology, applied in the direction of instruments, fluid mixers, chemical instruments and methods, etc., can solve the problem of inability to produce continuous, high-concentration respirable dust, inconvenient dust testing and research work, and inability to study dust Distributed status and movement conditions and other issues, to achieve the effect of convenient maintenance, reasonable structural design, and avoid direct contact with dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following describes the present invention in detail with reference to the drawings and embodiments.

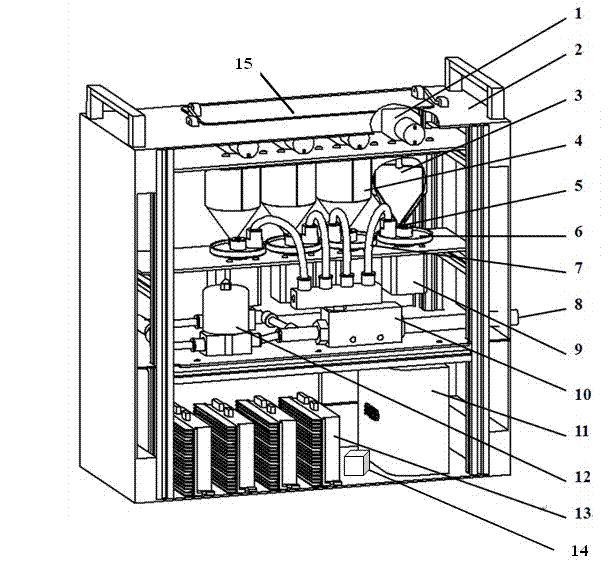

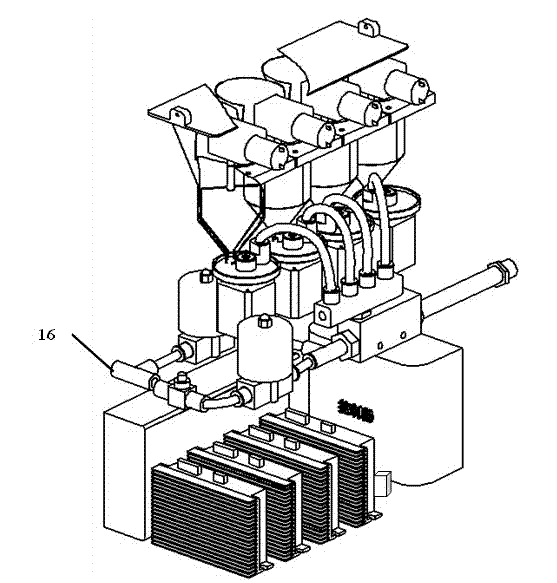

[0023] in figure 2 In the process, add dust of different particle sizes through the dust feeding port (15), and then start the dust generator, from image 3 The gas source inlet (16) in the middle part is supplied with the required pressure gas source. The microcomputer (11) first activates the solenoid valve (12) to make the negative pressure generating device (10) start to work, and negative pressure is generated in the negative pressure pipe (7) , The suction nozzle (6) is also ready to inhale dust. The controller (11) then controls the stirring motor (1) to rotate, and the stirring motor (1) drives the stirring rod (3) to rotate to stir the dust in the funnel (4) evenly and keep it flowing.

[0024] Then the stepper motor (9) controlled by the stepper motor driver (13) drives the turntable (6) to rotate, and the dust flows into the turntable in a linear form from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com