Integral rice processing machine

An integrated technology for rice processing, applied in applications, grain processing, agriculture, etc., can solve the problems of large manpower consumption, unhealthy workers, low processing efficiency, etc., and achieve the effect of simple structure, good working environment and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

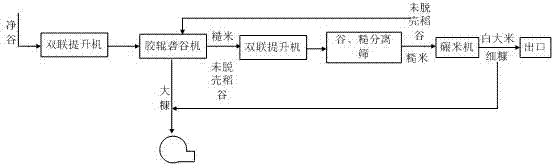

[0010] This equipment is composed of a rubber roller rice huller, a large bran separator, a gravity rice paddy separator, a sand-jet roller rice mill, and a double-joint upgrade.

[0011] The rice is poured into the rough rice hopper and sent to the de-stoner by the single elevator. After removing the miscellaneous stones, the rice is sent to the rubber roller rice huller by the double elevator, and the rice husk is removed. Separation. After separation, the bran is sucked out by the Dakang fan or sent to the pulverizer for crushing. Brown rice and unhulled paddy are sent to the paddy separating screen by double elevators. The screened, separated, and unhulled rice is sent to the hulling machine again for shelling, the brown rice flows into the rice mill, and the whitened rice flows out of the rice outlet through the rice milling chamber, and the fine bran is sucked out by the fan or into the pulverizer It is crushed and mixed with bran.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com