A tea grading machine

A classifier and tea technology, applied in solid separation, pre-extraction tea treatment, filtering and sieving, etc., can solve the problems of tea fragmentation, damage to tea leaves, mutual extrusion of tea leaves, etc., to achieve the effect of improving efficiency and maintaining stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below with reference to the accompanying drawings.

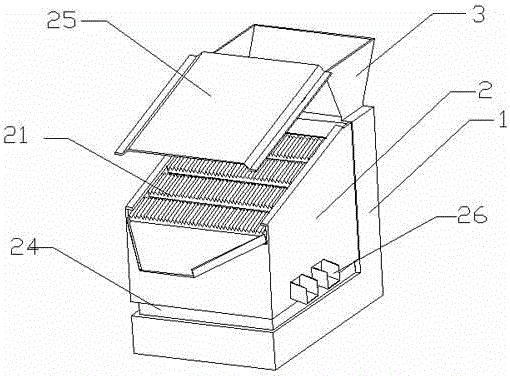

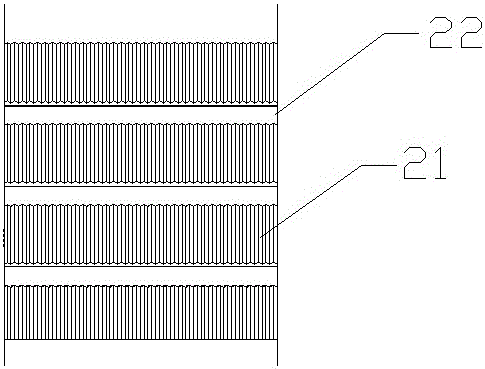

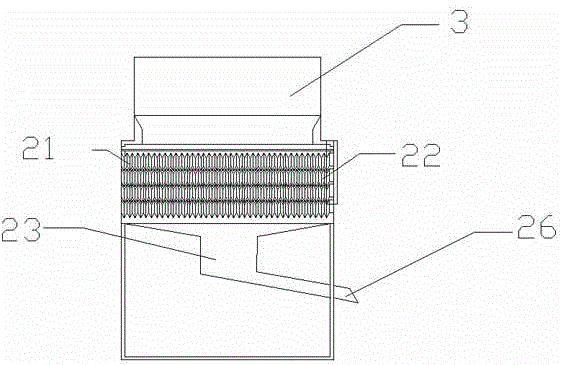

[0025] like figure 1 - Figure 4 As shown, the top of the frame 1 of the equipment is provided with a tea feeding device 3, and the outlet of the tea feeding device 3 is arranged above the comb-shaped dividing plate of the tea leaves grading and arranging device 2. A vibrating mechanism 24 is arranged above the base of the frame 1, and a tea grading and arranging device 2 is arranged above the vibrating mechanism 24. The top of the tea grading and arranging device 2 is a vertically arranged tea leaf partition, and a comb-shaped tea leaf partition There are four plates 21 in total, each comb-shaped tea partition 21 is provided with a plurality of V-shaped grooves 21a, and three tea grading grooves 22 are arranged between the four comb-shaped tea partitions 21, and the openings of the tea grading grooves 22 are respectively It is 1cm, 1.2cm and 1.6cm, and the tealeaves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com