Rolling mechanism used in magnetic levitation superconductivity rolling mill

A magnetic levitation and rolling technology, applied in the direction of rolling, metal rolling, metal rolling, etc., can solve the problems of finished steel plate surface oxidation, plate camber, edge wave, etc., to ensure product quality, improve efficiency, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

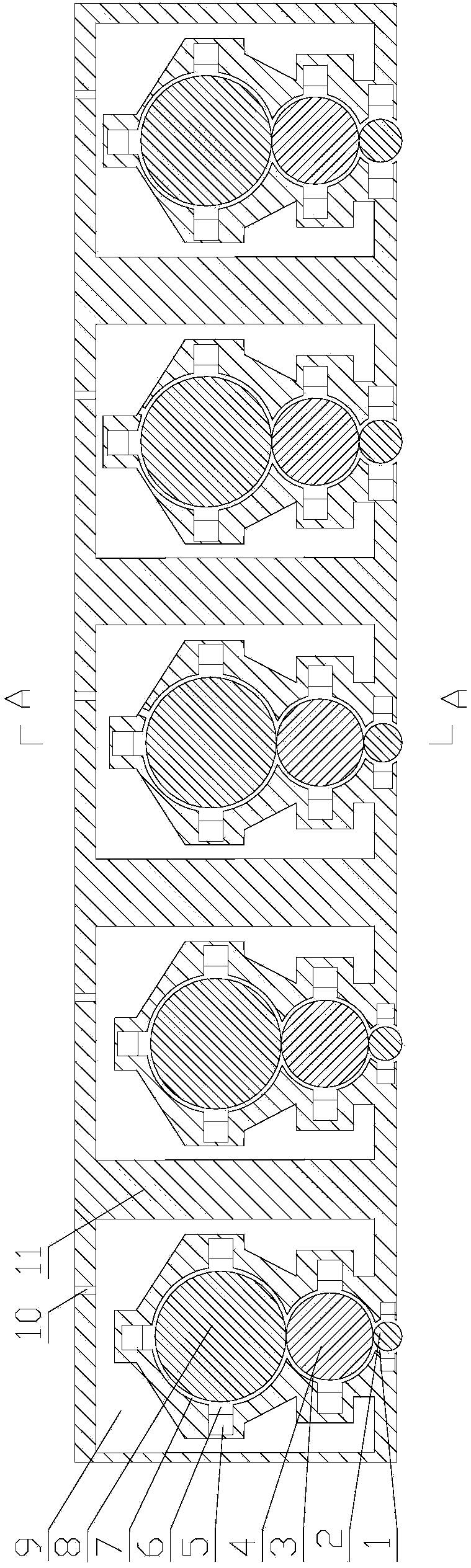

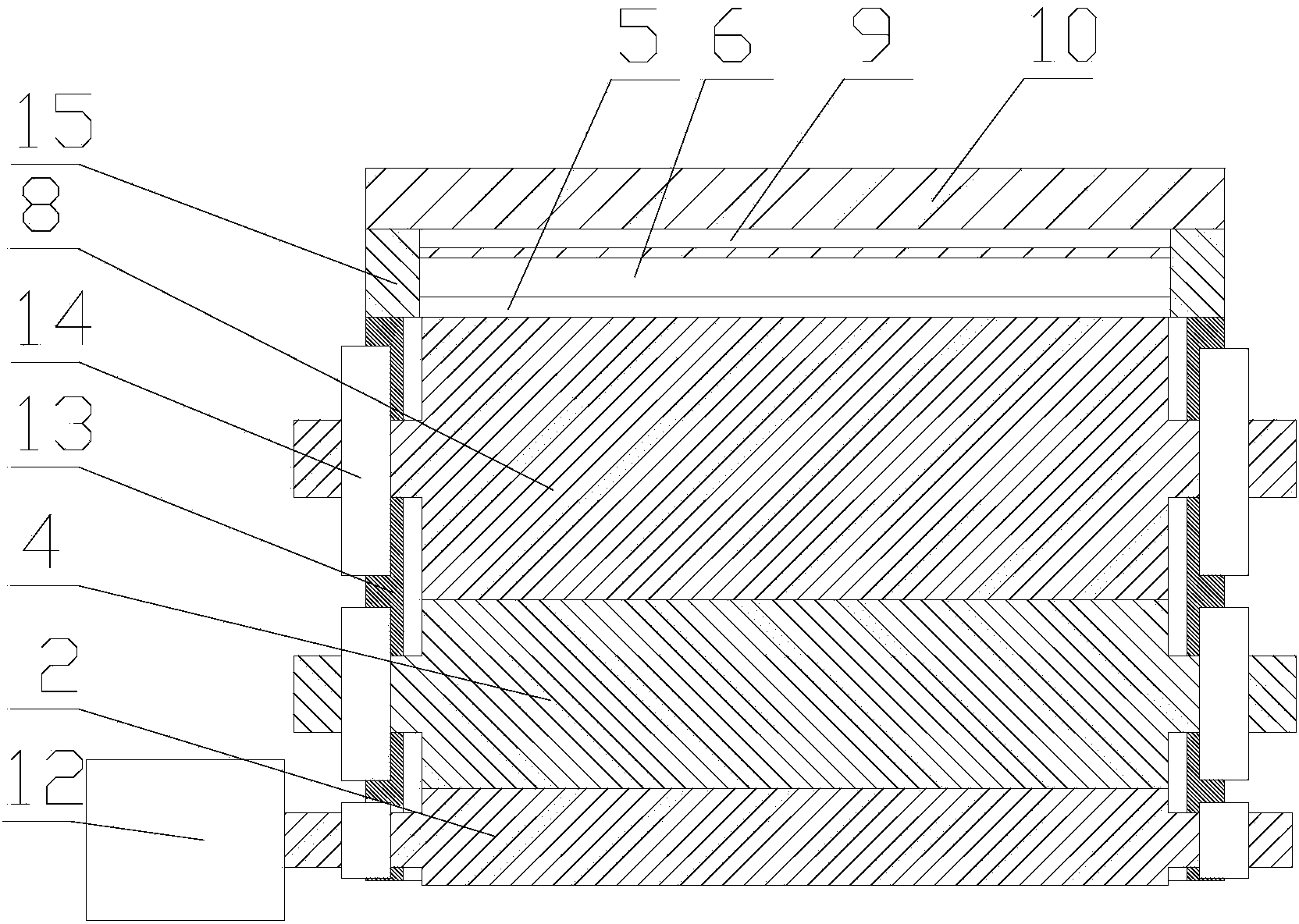

[0024] The specific embodiment of the present invention is shown in accompanying drawing, it is characterized in that described rolling mechanism comprises upper machine body 11, back-up roll 8, free roll 4, work roll 2, bearing block 5, permanent magnet 5; Upper machine body 11 has Multiple groups of back-up roll holes 7, free roll holes 3 and work roll holes 1 arranged longitudinally; permanent magnets are symmetrically processed on the upper part of the back-up roll holes 7 and both sides of the back-up roll holes 7, free roll holes 3 and work roll holes 1 Groove 6, permanent magnet 5 is installed in the permanent magnet groove 6, and is encapsulated by the permanent magnet groove cover 15; the back-up roll 8, free roll 4 and work roll 2 are respectively inserted into the back-up roll hole 7, free roll hole 3 and work roll hole 1, and installed on the roll hole cover 13 at both ends of each roll hole through the bearing housing 14; one end of the work roll 2 is connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com