Connecting rod milling lock notch apparatus

A locking and connecting rod technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment, etc., can solve problems such as large size errors, affecting work efficiency, and product quality cannot be guaranteed, so as to save clamping procedures, The effect of avoiding processing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing:

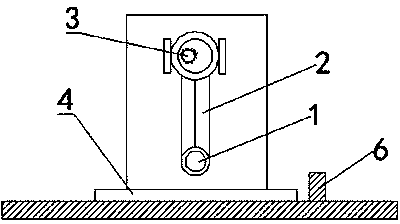

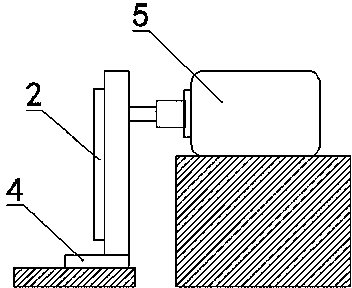

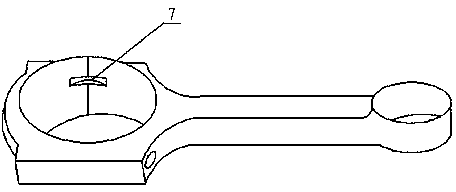

[0011] Such as figure 1 As shown, the present invention relates to a connecting rod milling lock device, which consists of a fixed rod 1, a connecting rod 2, a milling cutter 3, a moving table 4, a motor 5, a limit block 6, and a lock 7, and is characterized in that: The workbench 4 is provided with a fixed rod 1, the fixed rod 1 fixes the connecting rod 2 on the mobile workbench 4, the big end of the connecting rod 2 corresponds to the processing position of the milling cutter 3, and the lock 7 is located at the inner circle of the big end of the connecting rod 2 On the joint surface, the milling cutter 3 is installed on the motor 5, and the right side of the mobile table 4 is provided with a limit block 6, which is used to control the movement of the mobile table 4, so as to accurately control the processing depth of the lock 7.

[0012] When the present invention is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com