Tower crane upper support machining center

A technology of tower cranes and machining centers, which is applied to metal processing equipment, metal processing machinery parts, supports, etc., can solve problems such as failure to meet precision requirements, large error of upper supports, and high scrap rate, so as to save clamping procedures, The effect of avoiding errors, improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

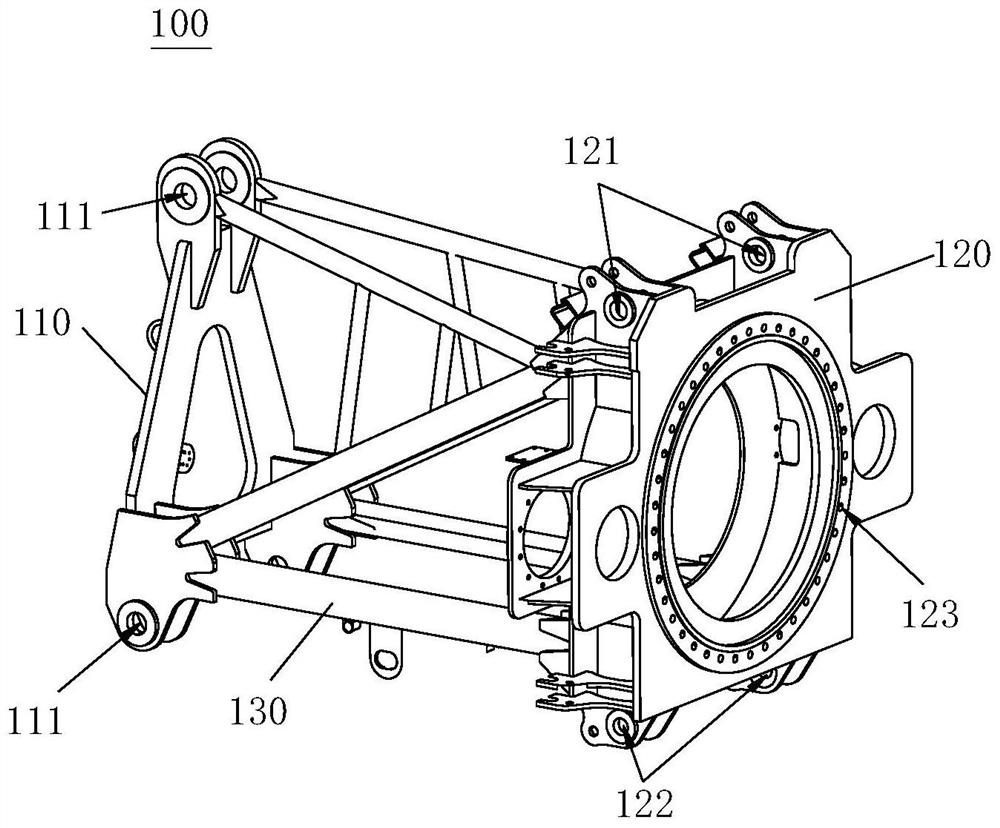

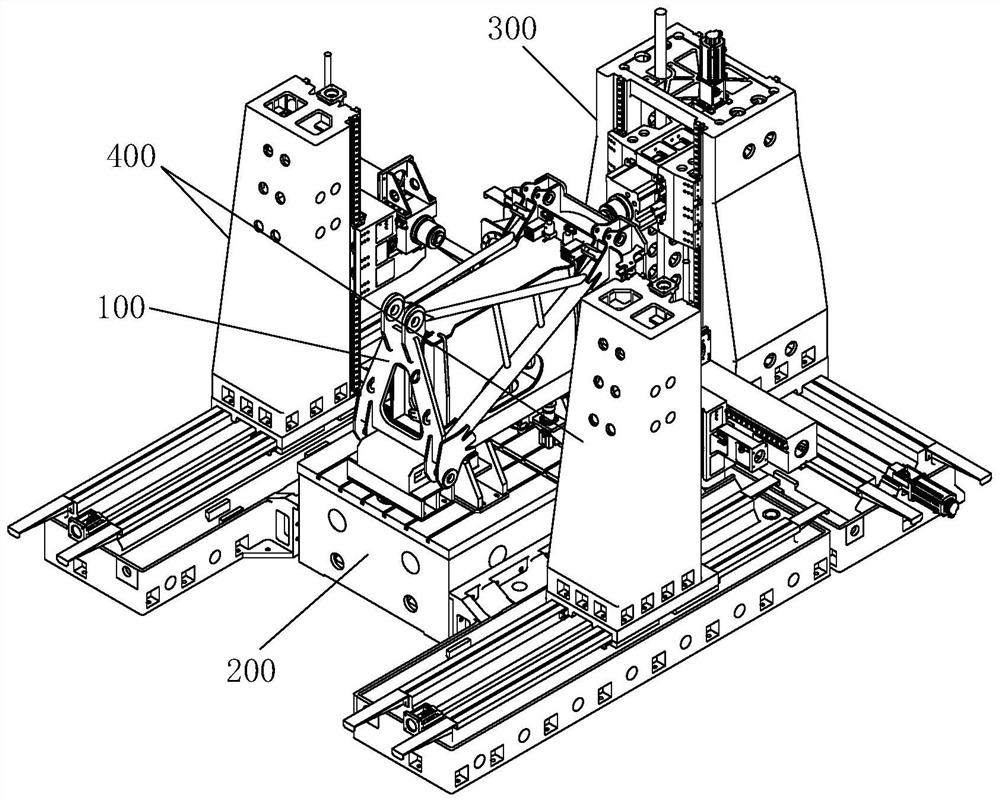

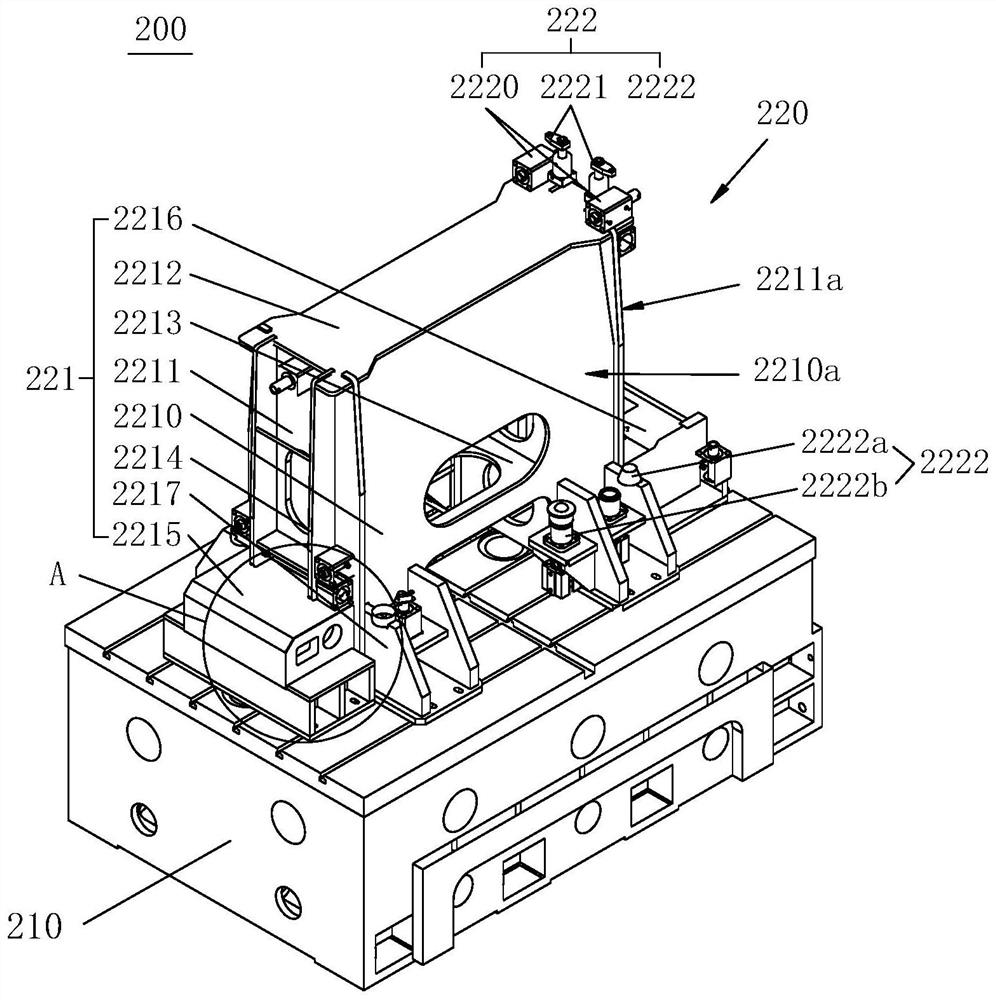

[0048] see figure 1 and figure 2 , This embodiment provides a tower crane upper support machining center for processing the end surface mounting holes 123 of the welded upper support 100 and the side mounting holes (111, 121, 122) on both sides. That is to say, the structural parts constituting the upper support 100 are assembled together by tailor welding, and then the machining center for the upper support of the tower crane provided in this example is processed on the end face and the two opposite sides of the upper support 100 respectively. End surface mounting holes 123 and side mounting holes. The side mounting holes are divided into a first side mounting hole 111 , a second side mounting hole 121 and a third side mounting hole 122 .

[0049] Specifically, the upper support 100 is a truss structure, the upper end of the upper support 100 is provided with a top seat 110, the lower end of the upper support 100 is provided with a base 120, and the top seat 110 and the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com