Robot system and processed product producing method

A robot system and robot arm technology, applied in the direction of robots, manufacturing tools, general control systems, etc., can solve the troublesome and complicated problems of robot system teaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach )

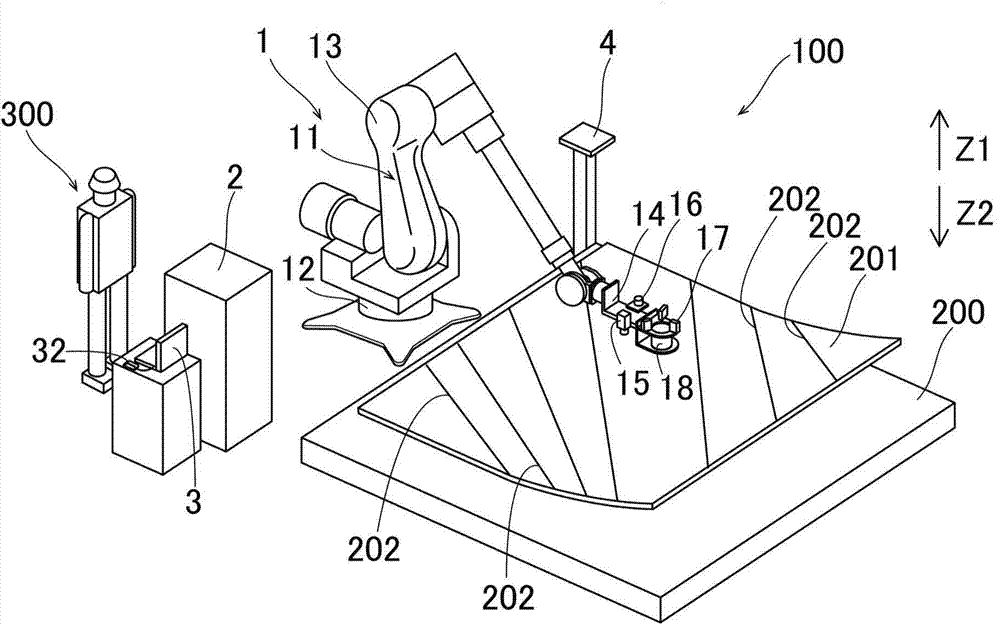

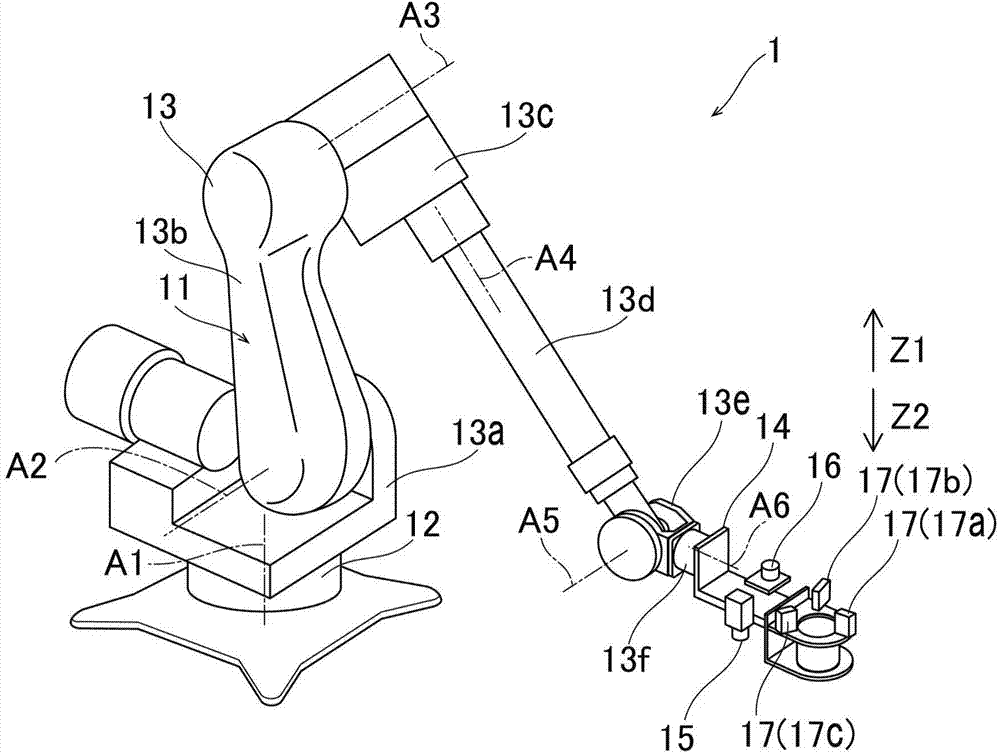

[0043] First, refer to figure 1 and figure 2 , the configuration of the robot system 100 of the first embodiment will be described.

[0044] Such as figure 1 As shown, the robot system 100 includes a robot 1 , a robot controller 2 , and a personal computer (PC) 3 . In addition, a stand 4 on which an imaging unit 15 to be described later is placed is provided near the robot 1 . Further, a workpiece 201 placed on a table 200 is arranged near the robot 1 . Furthermore, the workpiece 201 is made of, for example, a metal plate, and is formed into a curved surface so as to be curved upward (in the direction of the arrow Z1 ). In addition, a plurality of white lines 202 indicating processing positions (grinding positions) are provided in advance on the workpiece 201 . Also, the robot controller 2 is an example of a "controller". Also, PC3 is an example of an "input receiving unit". Also, the white line 202 is an example of a "processing position indicator".

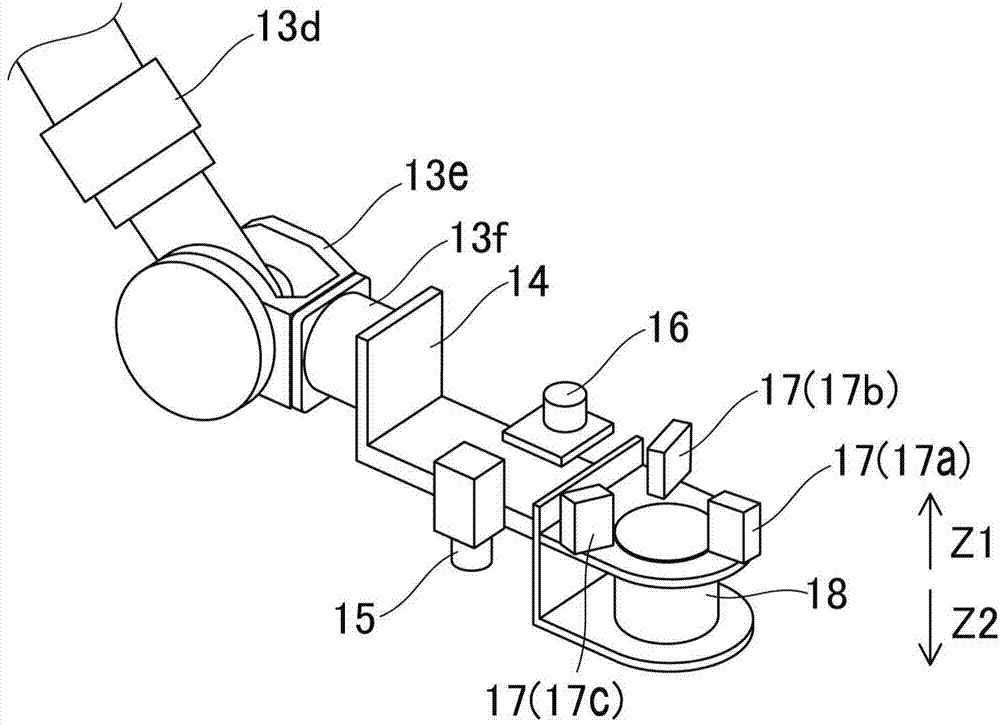

[0045] Such as ...

no. 2 approach )

[0073] Next, refer to Figure 16 and Figure 17 A second embodiment will be described. In this second embodiment, unlike the above-mentioned first embodiment in which the entire workpiece 201 is imaged by the imaging unit 15 at one imaging position, the case where the workpiece 201 is imaged by the imaging unit 15 at a plurality of imaging positions is performed. illustrate.

[0074] Such as Figure 16 and Figure 17 As shown, in the second embodiment, the robot controller 2 is configured to use the imaging unit 15 to image the workpiece 201 at a plurality of imaging positions by operating the robot arm 13, and to divide the images of the workpiece 201 at the plurality of imaging positions. The images are combined into one image. For example, in the second embodiment, the workpiece 201 is photographed by the imaging unit 15 at ten imaging positions along the X direction, and the workpiece 201 is photographed by the imaging unit 15 at ten imaging positions along the Y dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com