Aerofoils and vertical Tails horizontal measurement and point print system and method

A technology of horizontal measurement and wing, applied in the direction of measurement point marking, etc., can solve the problems of inconvenient operation, maintenance, multi-working space, occupation of inkers, etc., to achieve the effect of simple teaching and programming, guaranteeing accuracy, and easy modification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

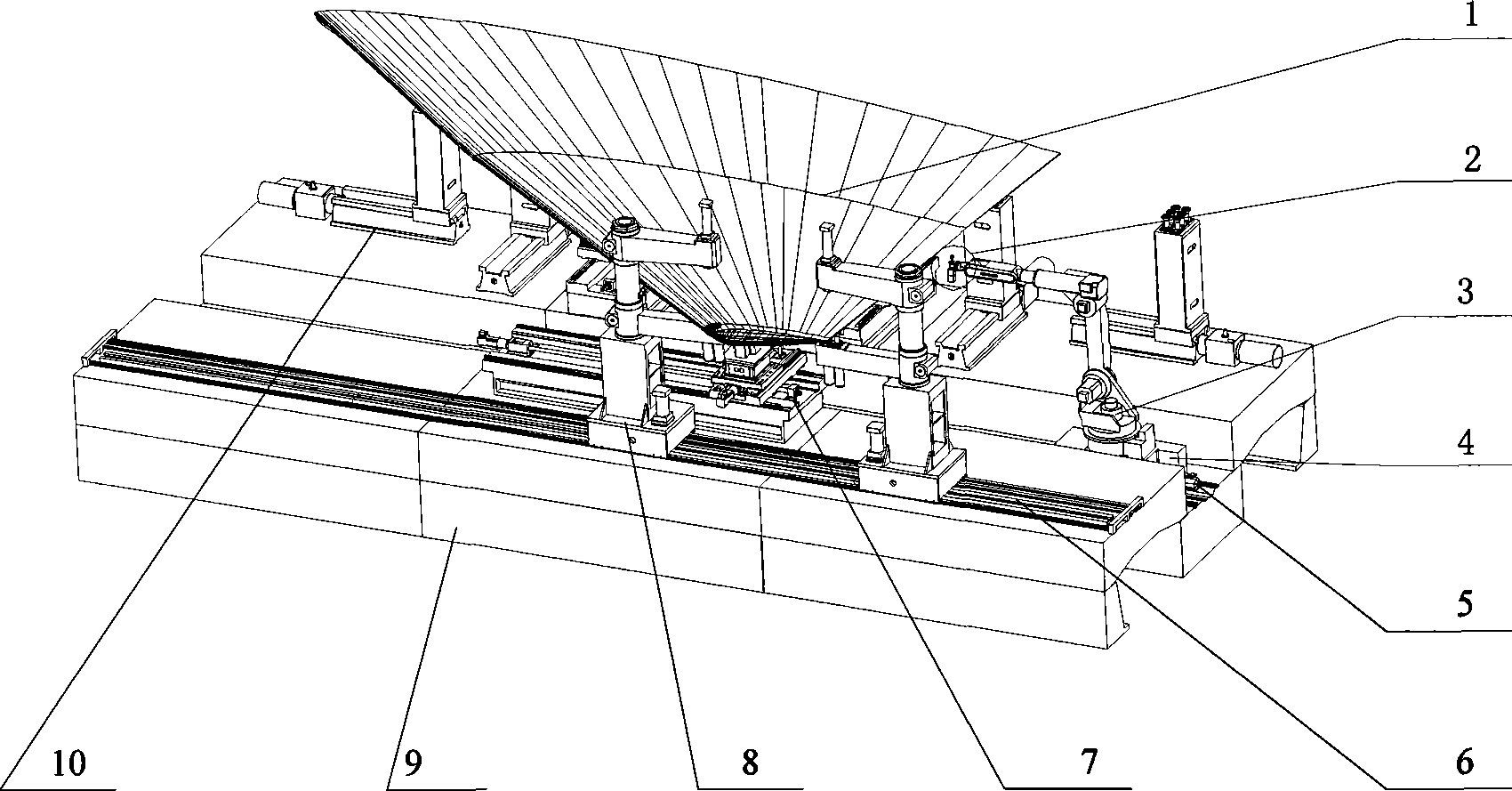

[0017] Such as figure 1 As shown, the aircraft wing and vertical tail horizontal measurement point marking system includes wing 1, dotting device 2, robot 3, robot mobile base 4, robot base guide rail 5, clamping device guide rail 6, and attitude adjustment three-coordinate positioner 7 , clamping device 8, wing attitude adjustment and finishing platform 9, flexible tooling 10, the wing attitude adjustment and finishing platform 9 is equipped with clamping device guide rail 6, robot base guide rail 5, three three-coordinate positioning for attitude adjustment 7, five flexible tooling 10, two clamping devices 8 are arranged on the clamping device guide rail 6, a robot mobile base 4 is provided on the robot base guide rail 5, a robot 3 is provided on the robot mobile base 4, and the robot 3 is not provided There is a dotting device 2, and the wing 1 is fixed on the wing attitude adjustment and finishing platform 9 by three attitude adjustment three-coordinate positioners 7, five...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com