Rubber roller

A rubber roller and rubber technology, applied in the field of rubber rollers, can solve the problems of low hardness, low sheet adhesion, low dyne value of polyurethane composite film, etc., and achieve the effect of high dyne value and large adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

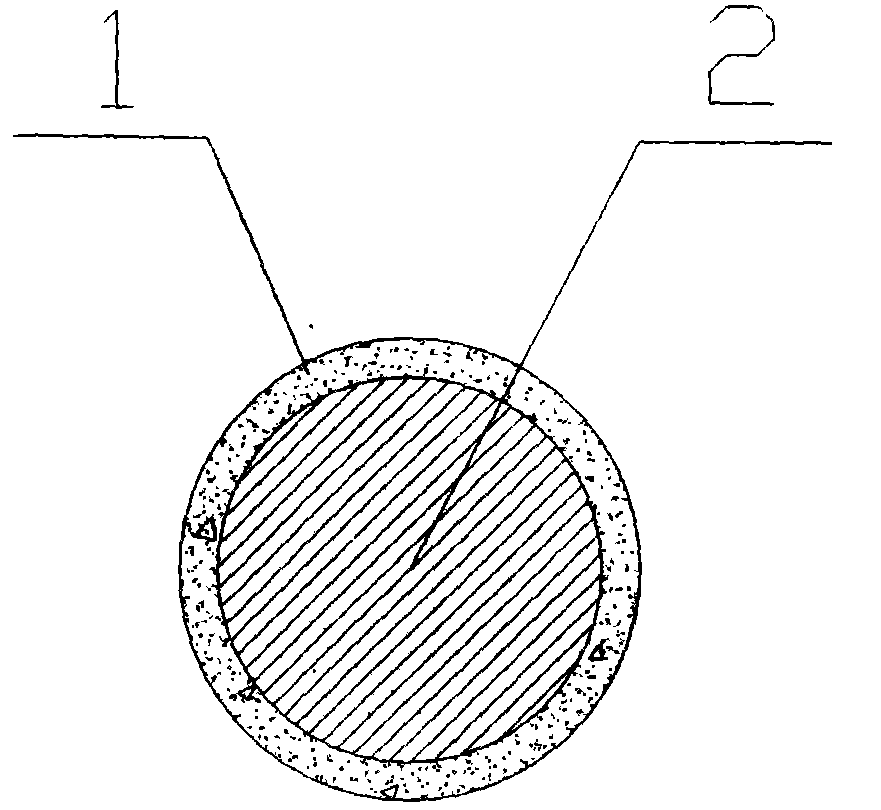

[0008] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0009] Such as figure 1 As shown, the polyurethane decorative film bonded rubber roller includes a rubber surface layer 1 and an iron mandrel shaft 2. It is characterized in that: the rubber surface layer 1 is tightly compounded on the iron mandrel shaft 2, and the particle size of the rubber surface layer 1 is 350. mesh, the hardness is 90 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com