Railway-vehicle trailer bogie frame

A rail vehicle and bogie technology, applied in the field of bogie frame and trailer bogie frame, can solve problems such as inability to meet the operation requirements of high-speed rail vehicles, meet the requirements of safe operation, avoid large stress areas, and overall anti-fatigue performance improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

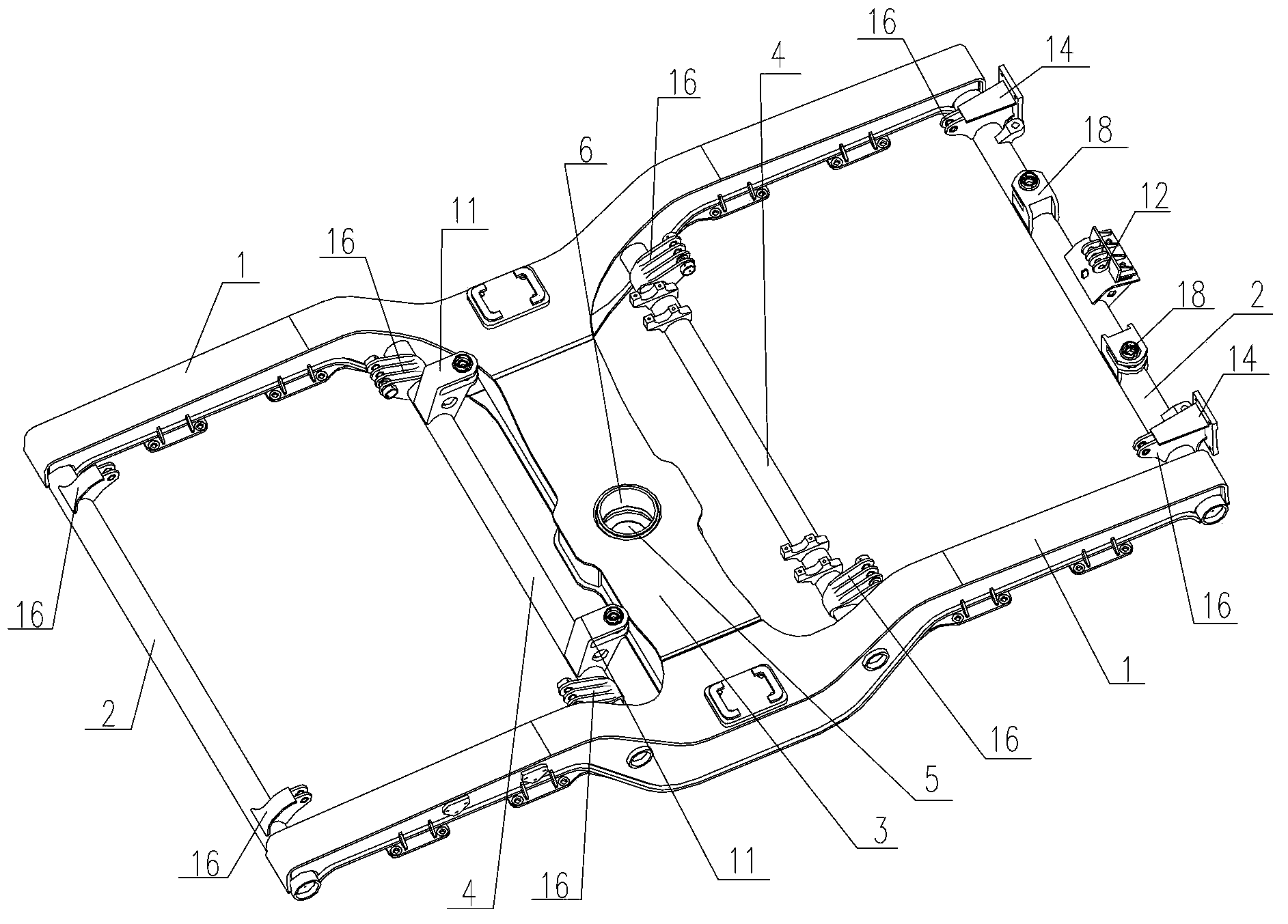

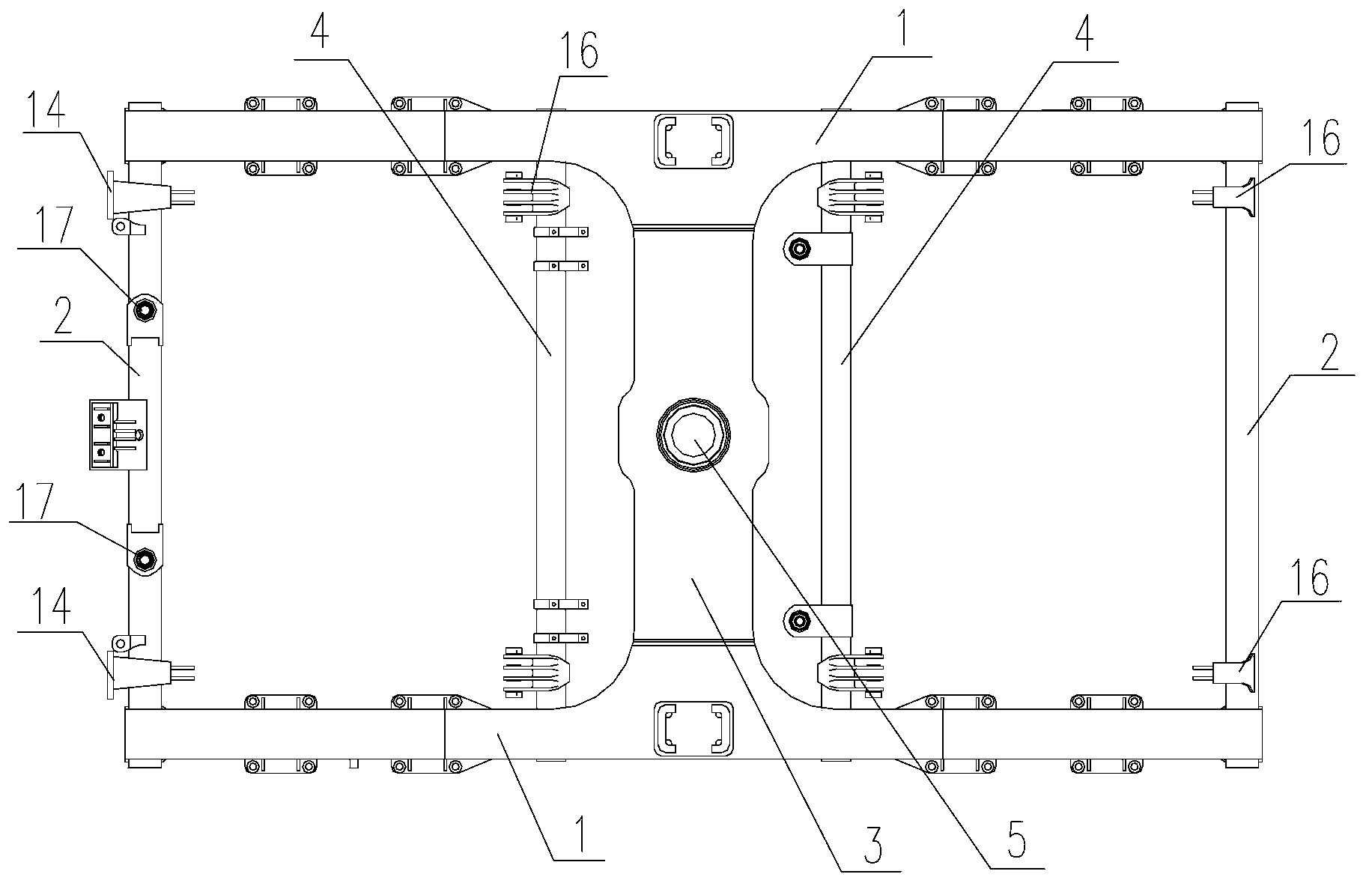

[0024] Such as Figure 1 to Figure 5 As shown, a rail vehicle trailer bogie frame is used for a trailer bogie in a rail vehicle, and is composed of two side beams 1, two end beams 2, a main beam 3 and two auxiliary beams 4 connected into a whole by welding frame structure. The frame 7 adopts an integral welded structure, which can improve the strength and rigidity of the overall structure of the frame, and can improve the connection stability of the equipment, and can effectively simplify the connection structure between the beams and meet the lightweight requirements.

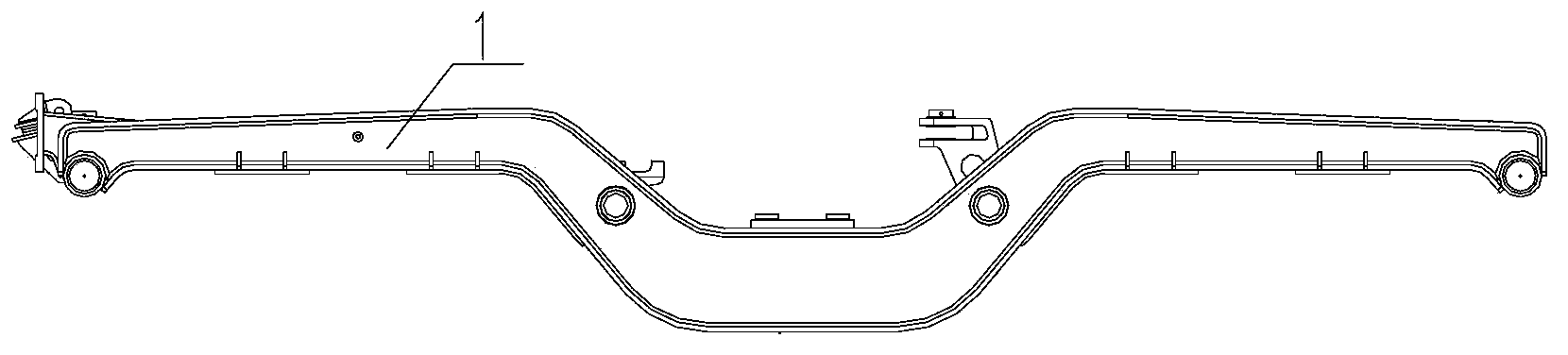

[0025] Such as figure 1 and image 3 As shown, the two side beams 1 are box-shaped structures, which are spliced by welding the top plate, the bottom plate and the two side plates, and the top plate, the bottom plate and the two side plates are all made of steel plates. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com