A method and device for real-time preparation of CO gas

A technology of gas and cylinder, which is applied in the field of real-time preparation of CO gas, can solve the problems of hidden safety hazards in storage and use, and achieve the effect of solving the pressure of the tank and ensuring high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

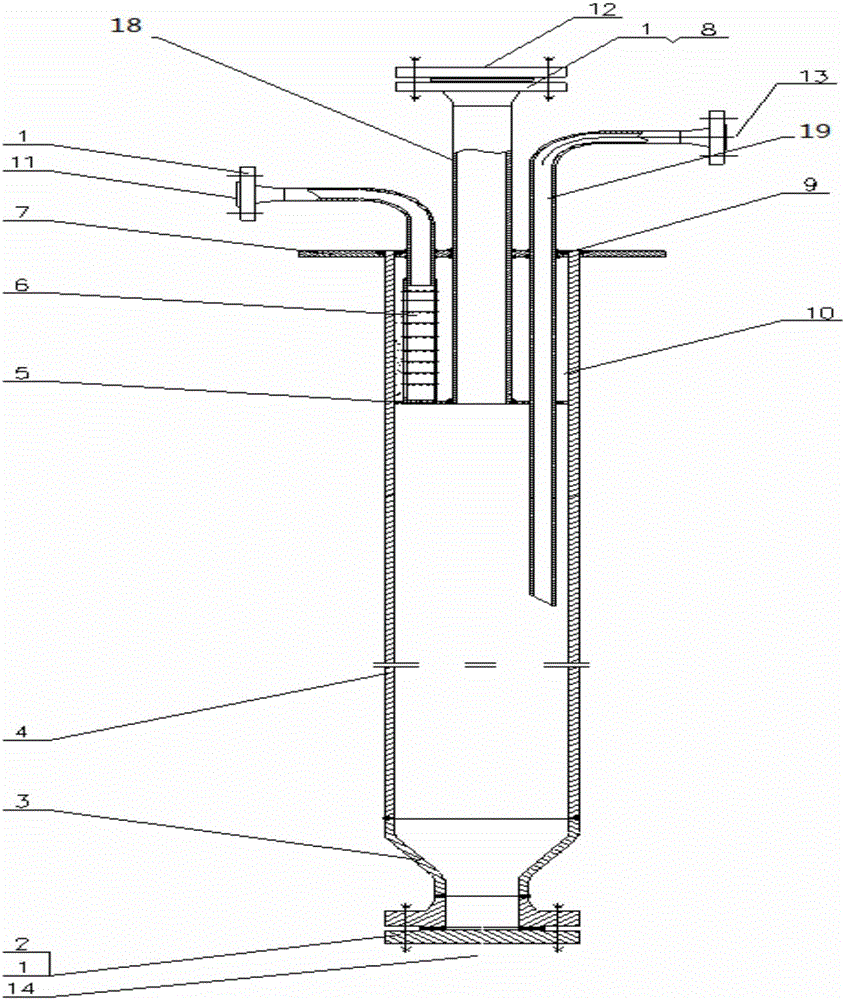

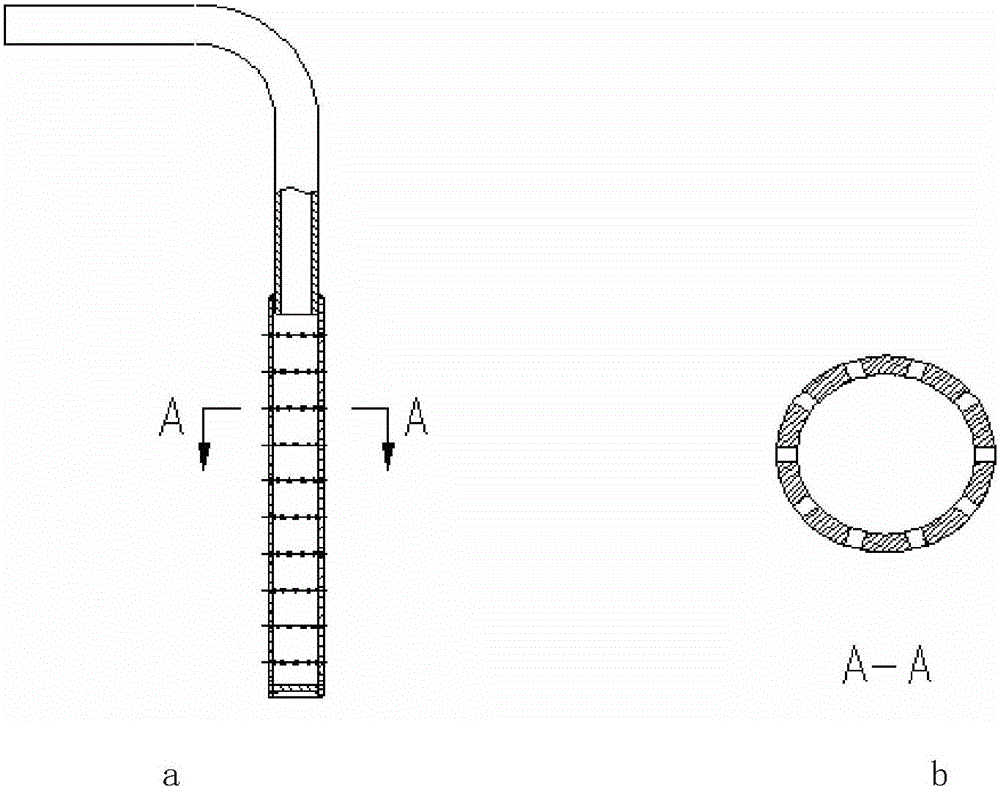

[0021] This embodiment is a device for preparing CO gas in real time, including a cylinder body 4 , a support plate 5 , an exhaust pipe 6 , a contraction section 3 , a support plate 7 and an aluminum silicate fiber felt 10 .

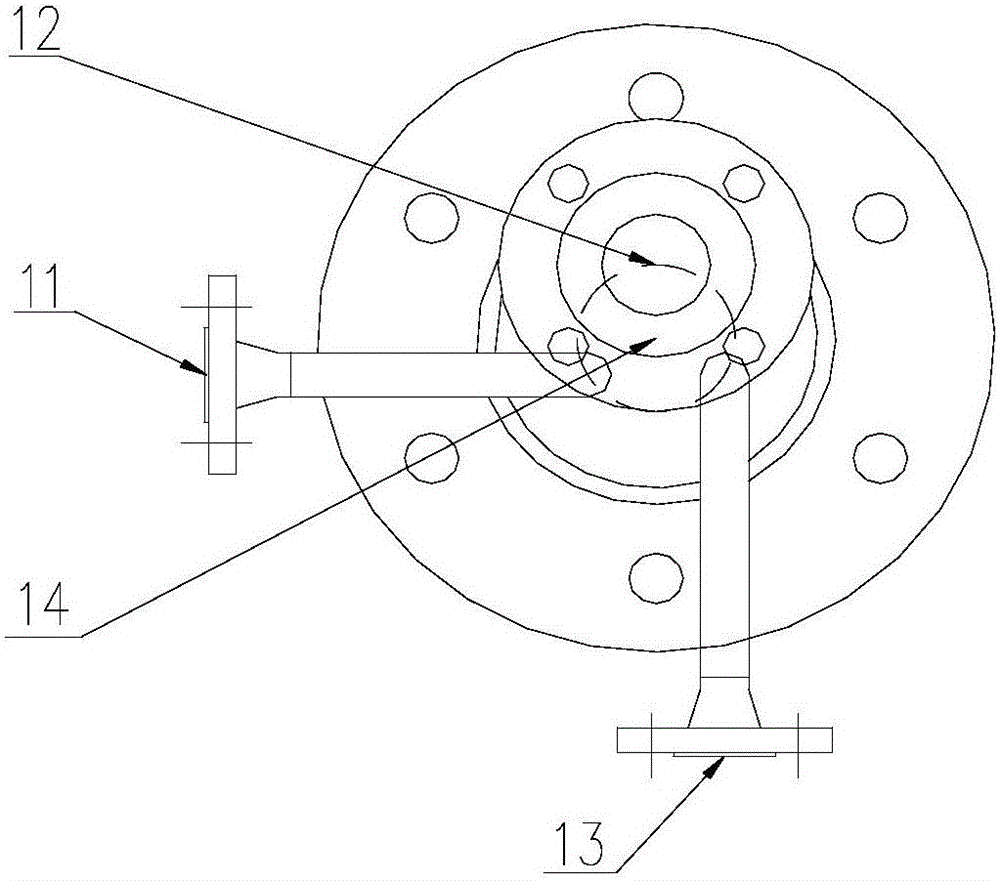

[0022] The lower end of the cylinder body 4 is welded with a shrinkage section 3 , and the upper end port of the cylinder body 4 is welded with a support plate 7 . One end of the charging pipe 18 passes through the eccentric through hole on the support plate 7 and is loaded into the barrel 4; a flange 8 is installed at the charging port 12 of the charging pipe 18 . One end of the exhaust pipe 6 passes through the eccentric through hole on the support plate 7 and is loaded into the cylinder 4; a flange 1 is installed at the exhaust port of the exhaust pipe 6 . One end of the air inlet pipe 19 passes through the eccentric through hole on the support plate 7 and is packed into the cylindrical body 4 . The positions of the charging pipe 18, the exhaust pipe...

Embodiment 2

[0028] This embodiment is a method for real-time preparation of CO gas with a content of 2-10% by using the device for real-time preparation of CO gas, including the following steps:

[0029] Step 1, add activated carbon. Described activated carbon is made of charcoal or coconut shell, adopts charcoal to make in the present embodiment. Activated carbon is fed into the CO reaction tank from the feed port 12 of the CO reaction tank until the CO reaction tank is full. Seal the feed port of the CO reaction tank.

[0030] Step 2, the CO reaction tank is heated. The CO reaction tank is heated to 800-850°C by a heating furnace. The industrial nitrogen produced by membrane nitrogen production is passed into the CO reaction tank. The flow rate of the nitrogen is 5~10m 3 / h; the nitrogen concentration is 98.5-99.0%. After the nitrogen gas is introduced, the activated carbon in the CO reaction tank reacts with the trace oxygen in the nitrogen gas to form a mixed gas of CO and nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com