Jun porcelain body glaze formula mixing system and method

A formulation and glaze technology, applied in the field of Jun porcelain blank glaze formulation deployment system, can solve the problems of lack of theoretical and method guidance, low yield, waste of resources, etc., achieve clear business logic, reduce development efficiency, and improve social benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

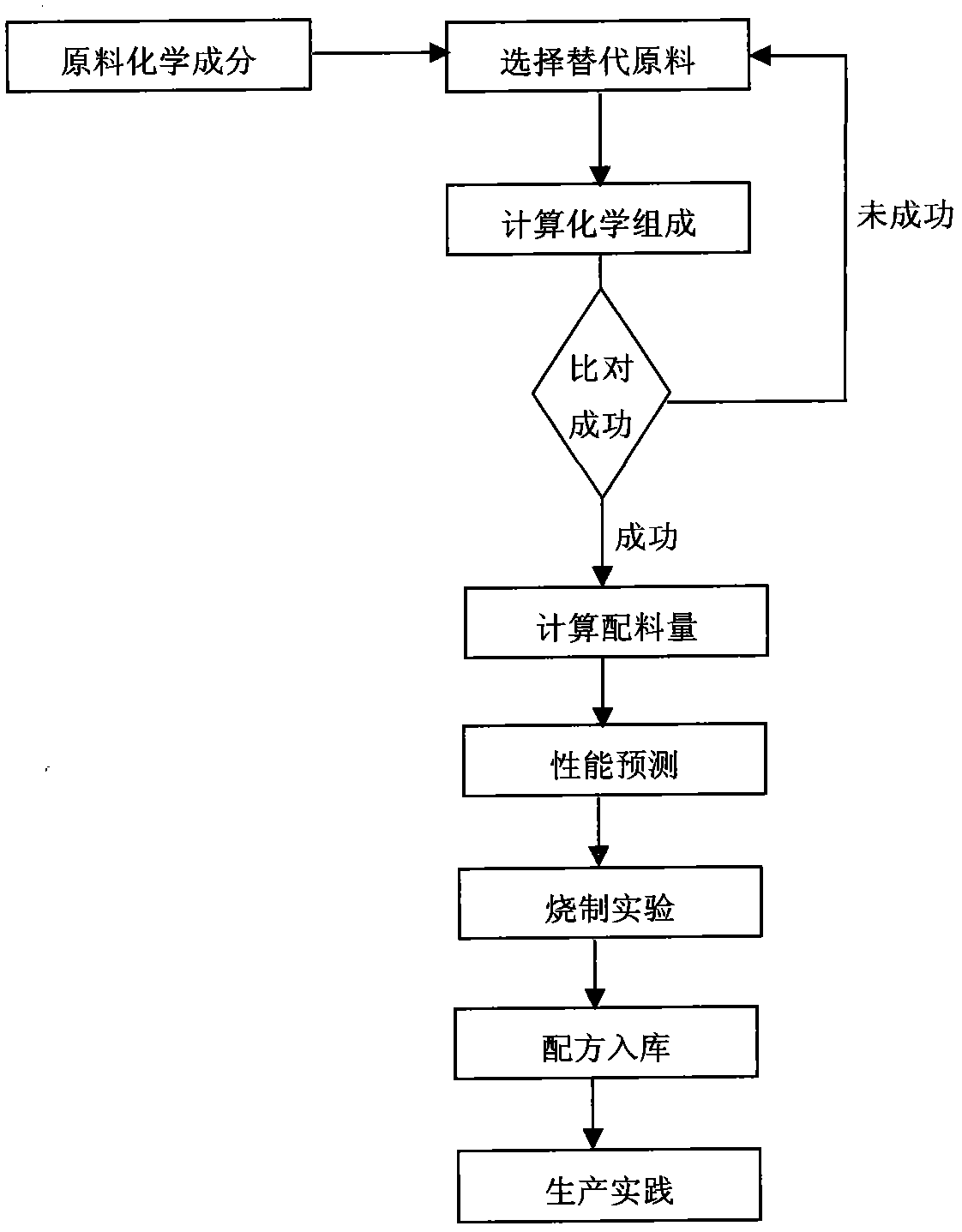

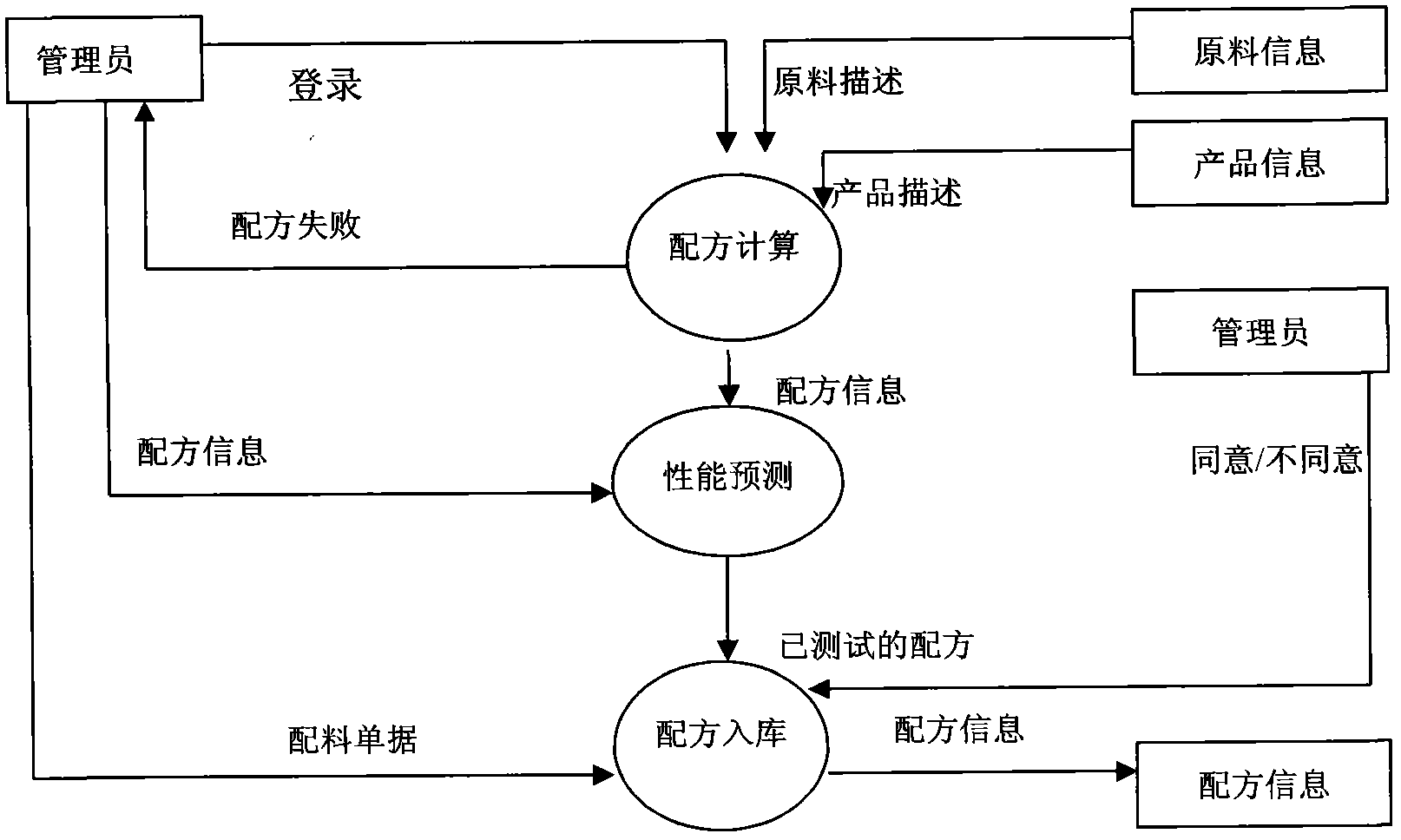

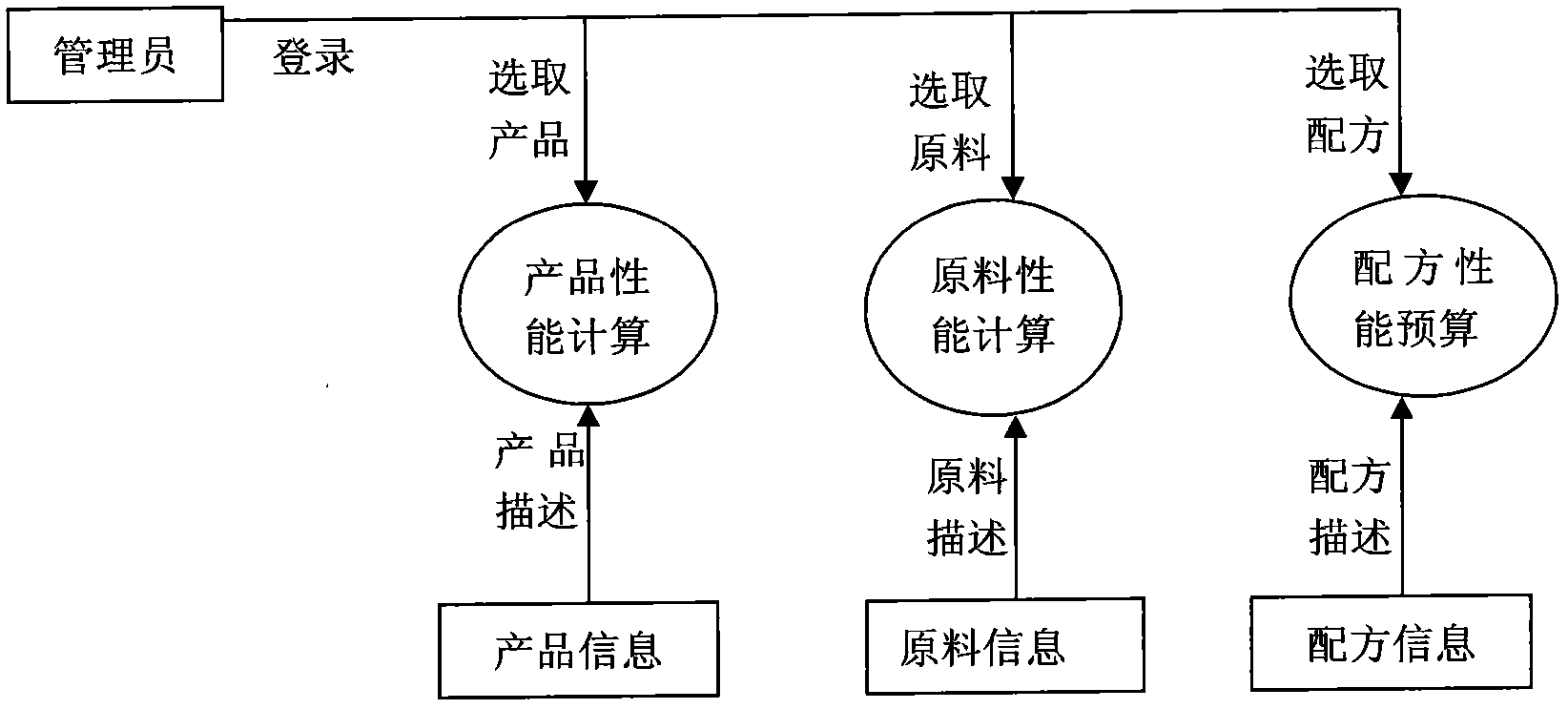

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and specific implementation.

[0027] A system for formulating glazes for Jun porcelain blanks, including four modules: data management, formula calculation, performance calculation, and system maintenance.

[0028] The data management module is used for the user to input and manage the basic resource data of the Jun porcelain blank glaze formulation system, including raw material information, raw material chemical composition, oxide information, product formula information, product chemical composition, blank glaze information, etc. Data addition, deletion, modification and other operations:

[0029] The formula calculation module is used for the user to manage the intelligent calculation involved in the Jun porcelain blank glaze formulation system, including the calculation formula of the known Jun porcelain blank glaze (or blank glaze formula)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com