Method of removing procymidone residue in ginseng and American ginseng extracts by resin method

A resin, pore adsorption technology, used in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

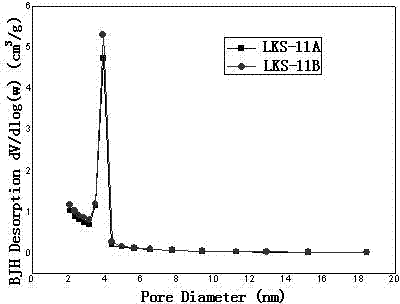

Embodiment 1

[0042] Add 1500mL of purified water into a 3000ml reactor equipped with a thermometer, condensing reflux device and stirring, add 15g of gelatin while stirring, raise the temperature to 60°C, after the gelatin is completely dissolved, add 50g of styrene, 450g of Divinylbenzene, 100g toluene, 100g dichloroethane, the mixture of 2.5g benzoyl peroxide, etc. After the organic mixture forms uniform droplets of a certain size in the dispersion medium solution, the temperature is raised to 76 ° C, and the reaction is carried out for 5 hours. The temperature was raised to 80° C. to cure for 9 hours to stop the reaction. Rinse with a large amount of water, sieve, control the particle size between 20-70 mesh, and dry to obtain macroporous polystyrene resin white balls. Take 100g of white balls, add 600g of dichloroethane, swell at room temperature for 2 hours, add the catalyst anhydrous aluminum trichloride (3.33g / 30min) in 3 times, and raise the temperature to 80°C for 10h. Cool down,...

Embodiment 2

[0044]Add 1500mL of purified water into a 3000ml reactor equipped with a thermometer, condensing reflux device and stirring, add 15g of gelatin while stirring, raise the temperature to 60°C, after the gelatin is completely dissolved, add fully mixed 150g of styrene, 350g The mixture composed of divinylbenzene, 200g toluene, 2.5g benzoyl peroxide, etc. After the organic mixture forms uniform droplets of a certain size in the dispersion medium solution, heat up to 76°C, react for 5 hours, heat up to 80°C and solidify for 9 hours, the reaction stopped. Rinse with a large amount of water, sieve, control the particle size between 20-70 mesh, and dry to obtain macroporous polystyrene resin white balls. Take 100g of white balls, add 600g of dichloroethane, swell at room temperature for 2 hours, add catalyst anhydrous ferric chloride (6.67g / 30min) in 3 times, raise the temperature to 80°C for 10h. Cool down, extract dichloroethane, wash with water, put it into a Soxhlet extractor, ex...

Embodiment 3

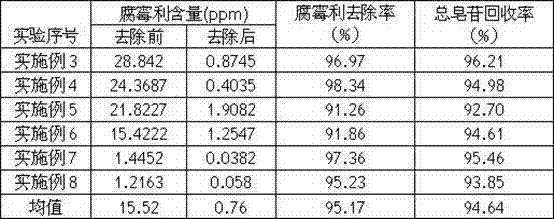

[0048] Precisely weigh the LKS11 resin (Example 1) and place it in a suitable container, soak it in 95% ethanol for 24 h, and wash it with distilled water until it has no alcohol smell. After washing away the alcohol smell, soak in 10% NaOH solution for more than 3 hours, then wash with distilled water until neutral; finally soak in 10% HCl solution for more than 3 hours, wash with distilled water until neutral, and wet-pack the pretreated resin in column. Accurately weigh 20.00 g of ginseng extract, add 200 mL of distilled water, stir and let it stand for 2 h, then fully mix to prepare a 0.1 g / mL sample solution. Pipette 2 times the volume of the resin sample solution into the resin column, absorb for more than 1 h, and control the flow rate of 2-5 mL / min to pass through the column. First wash with distilled water of 1 times the volume of the resin, then elute with 50% ethanol of 6 times the volume of the resin, and collect the eluate. The evaporation equipment is sealed to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com