Adapter for dry-hanging fiber-ceramic board and dry-hanging method for fiber-ceramic board

A technology for adapters and porcelain plates, which is applied in the directions of covering/lining, construction, and building materials, and can solve the problems that the fiber-ceramic plate cannot adjust its own flatness, cannot be adjusted back and forth, and the fiber-ceramic plate is easy to fall off, etc., to achieve Good appearance, good flatness and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

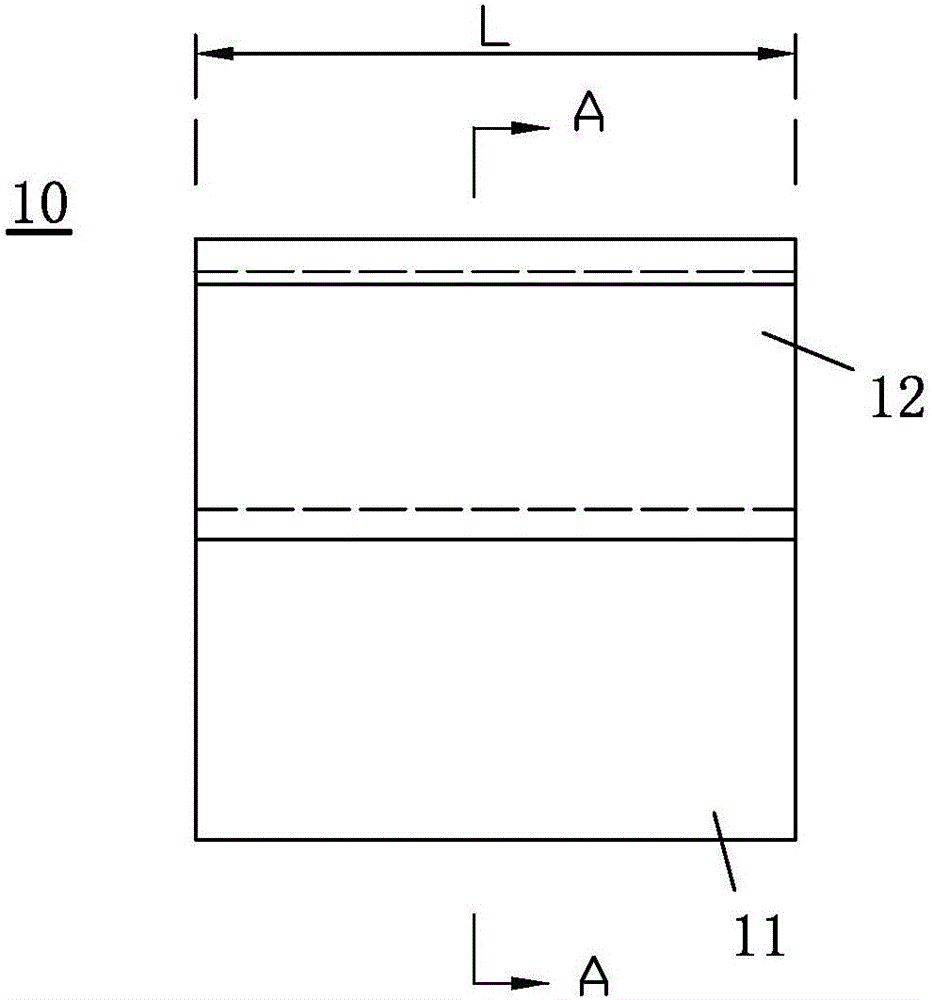

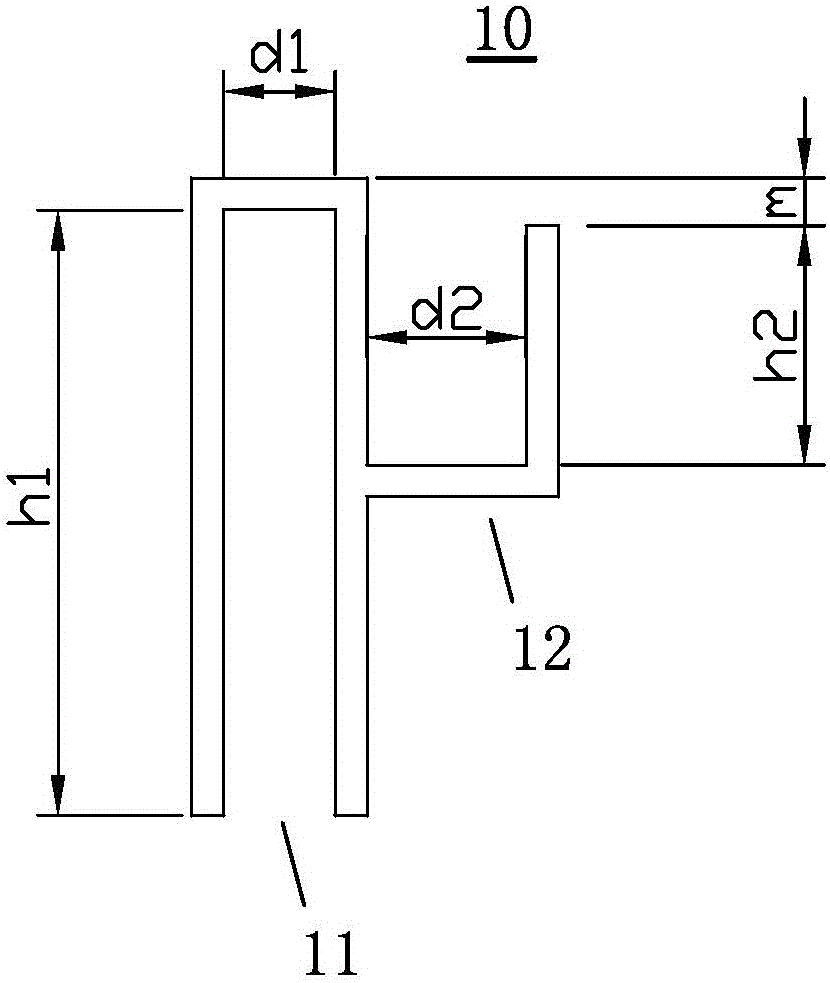

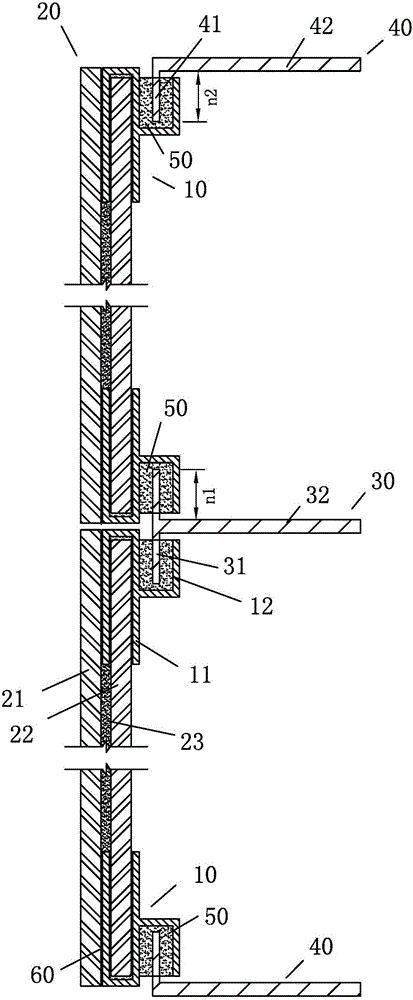

[0021] Such as Figure 1 to Figure 2 As shown, the adapter 10 for dry-hanging fiber-ceramic boards of the present invention includes a first groove body 11 and a second groove body 12 with two notch directions set in opposite phases and a U-shaped cross section for inserting fiber-ceramic boards 20 One side groove wall of the first groove body 11 of the inner layer plate 22 is used as a side groove wall of the second groove body 12 for inserting the pendant, that is, the first groove body 11 and the second groove body 12 share a common The connection is realized by means of the middle groove wall, and the adapter 10 of the present invention is integrally formed.

[0022] In the present invention, the hanger can be a T-shaped hanger or an L-shaped hanger, etc., the T-shaped hanger 30 is composed of two insertion parts 31 and a fixed part 32, and the L-shaped hanger 40 is composed of an insertion part 41 and a fixed part 42 constitute. The T-shaped hanger 30 and the L-shaped h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com