Carbon fiber composite material reciprocating compressor valve plate and preparation method thereof

A composite material and carbon fiber technology, used in mechanical equipment, liquid variable volume machinery, variable volume pump components, etc., can solve the problems of low fatigue resistance and high noise, and achieve increased fatigue resistance light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

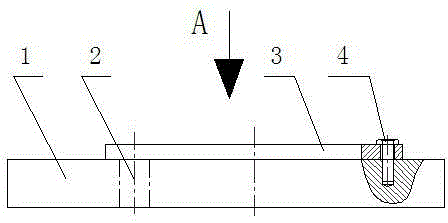

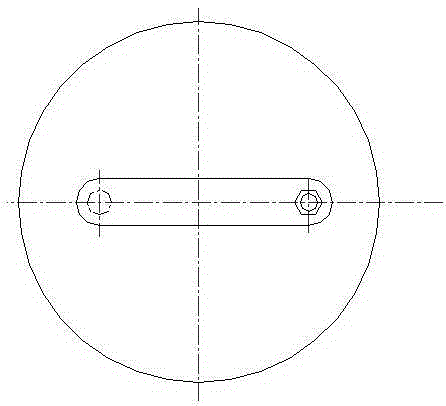

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the valve plate 3 of the present invention is a strip-shaped valve plate, the ratio of length to width is 1:0.2~0.1, the thickness is 0.2~10mm, the two ends of the length direction are semicircular arc-shaped, and one end has a reciprocating The hole connected to the valve seat 1 of the reciprocating compressor is fixed on the valve seat 1 of the reciprocating compressor with screws 4, and the other end is covered on the suction and discharge holes 2 of the reciprocating compressor, and the suction and discharge holes of the reciprocating compressor are covered. The semi-arc diameter of the valve plate on the air hole 2 should be 10-20mm larger than the diameter of the suction and exhaust holes 2 of the reciprocating compressor; according to the required thickness of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com