Fan blade balance correction method

A balancing and fan blade technology, which is applied to the components of pumping devices for elastic fluids, non-variable-capacity pumps, machines/engines, etc., can solve the problems of manpower and man-hours, poor balance effect, weight error, etc. , to achieve the effect of saving man-hours and achieving the best balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

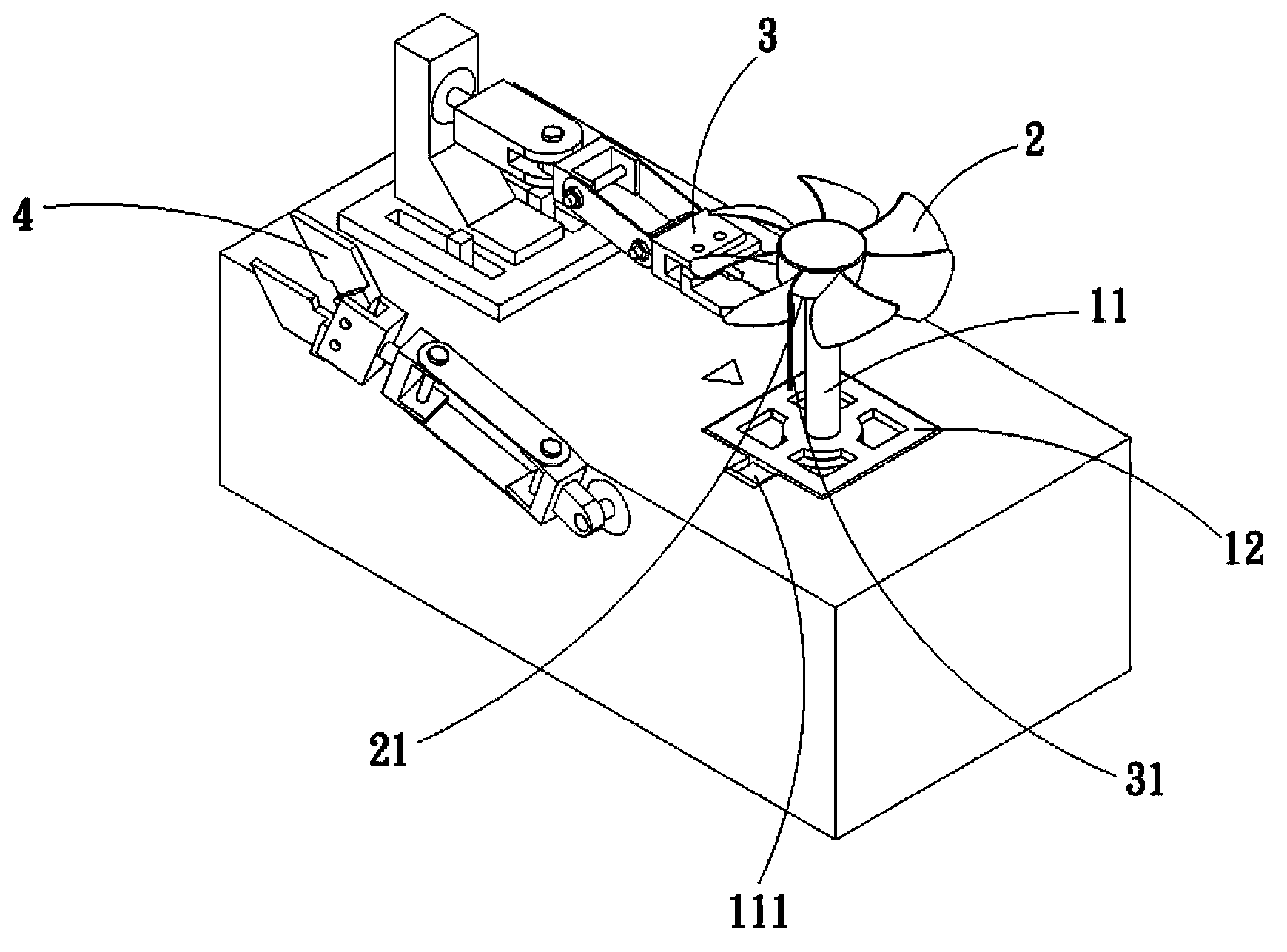

[0038] The above-mentioned objects of the present invention and their structural and functional characteristics will be described with reference to the preferred embodiments of the accompanying drawings.

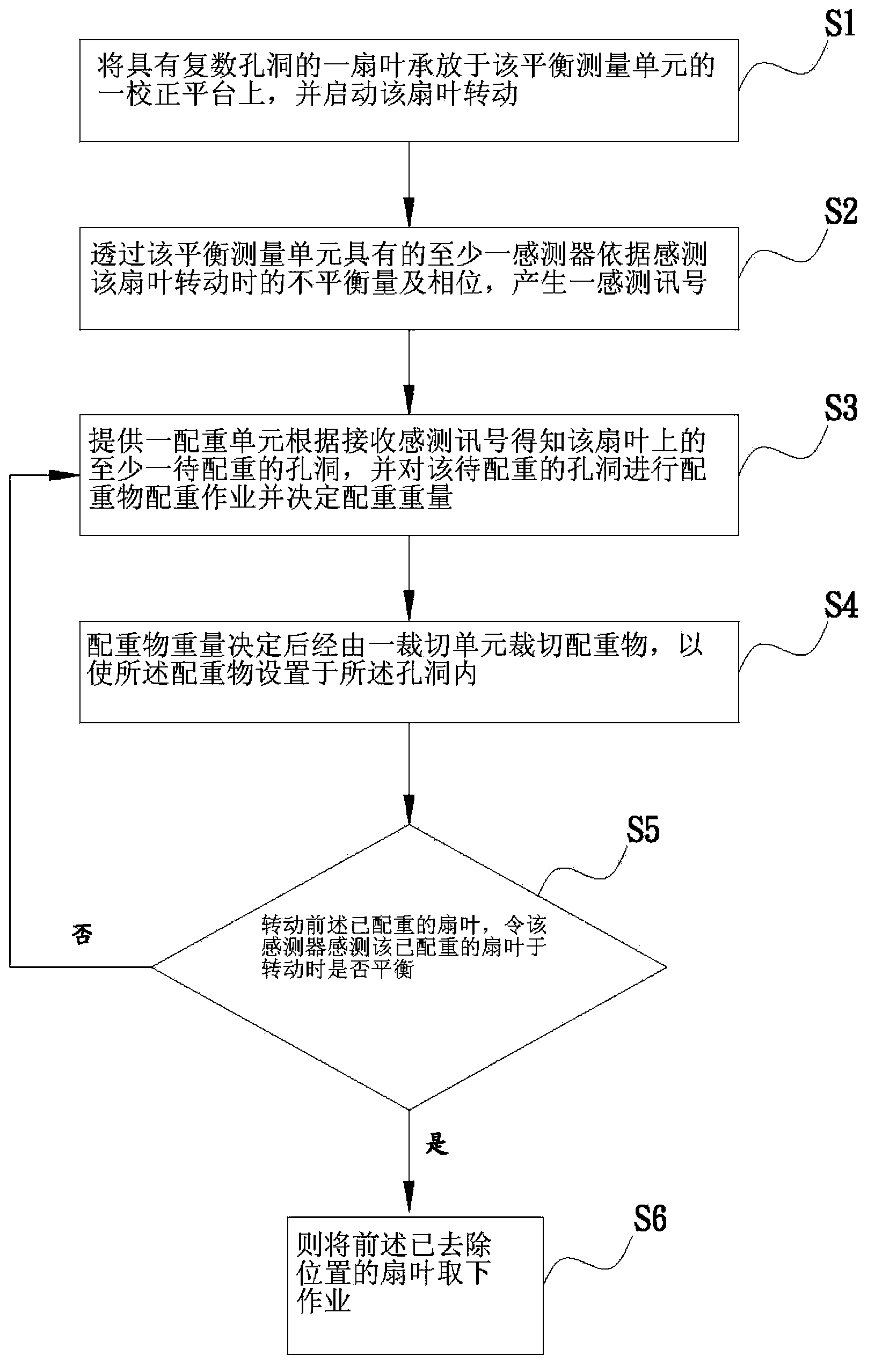

[0039] Please refer to Fig. 1 and Figs. 2A-2D, which are the flow chart and implementation diagram of the first embodiment of the fan blade balance adjustment method of the present invention. As shown in the figures, the fan blade balance adjustment method of the present invention It is applied to a balance adjustment device 1, the balance adjustment device 1 has a balance measurement unit 11, and the fan blade balance adjustment method includes the following steps:

[0040] (S1) a fan blade with a plurality of holes is supported on a calibration platform of the balance measurement unit, and the fan blade is started to rotate;

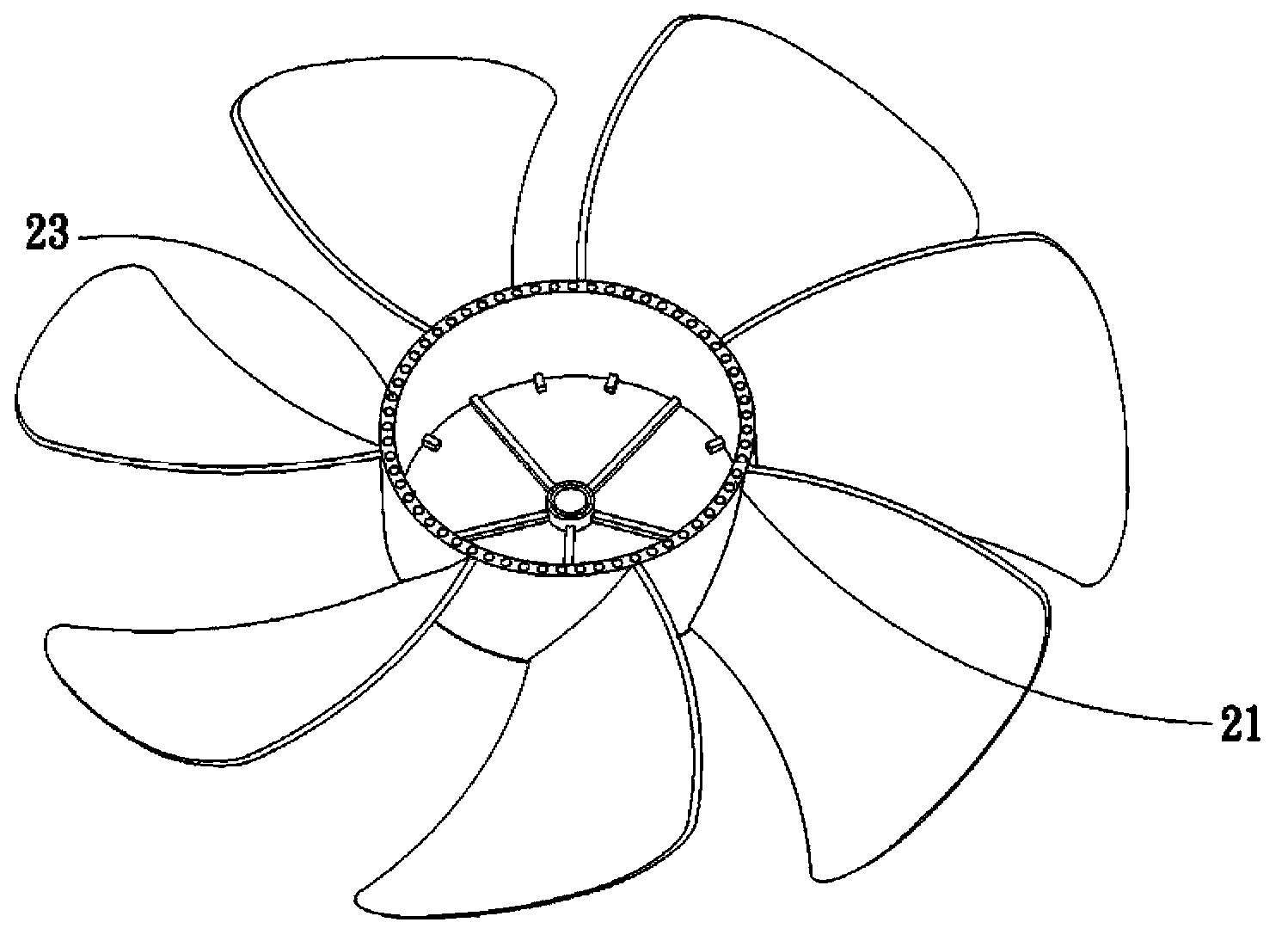

[0041] A fan blade 2 is provided, the bottom 21 of the fan blade 2 has a plurality of holes 23 in this embodiment, and the fan blade 2 is supported ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com