Rubber shoe forming clamp rubber and preparation method thereof

A technology of rubber shoes and fixtures, which is applied in the field of rubber shoes forming fixture rubber and its preparation, which can solve the problems of low wear resistance, short service life, small friction, etc., and achieve good wear resistance and folding resistance, and anti-wet skid The effect of high coefficient and excellent wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

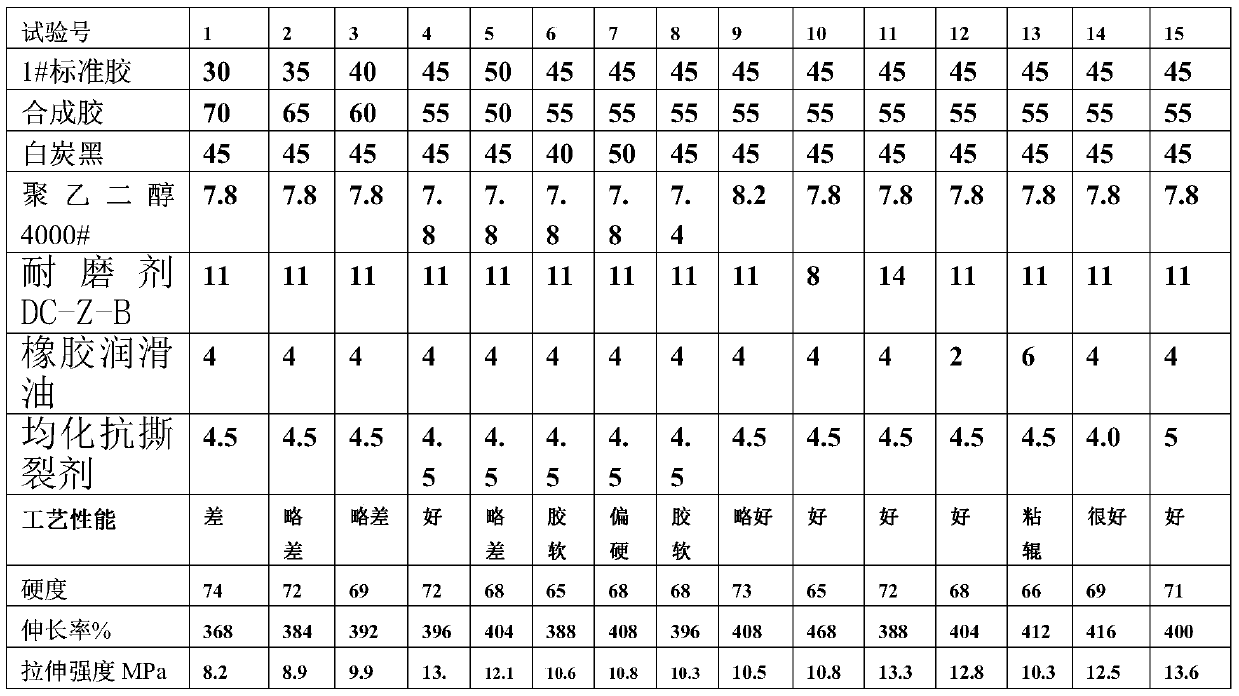

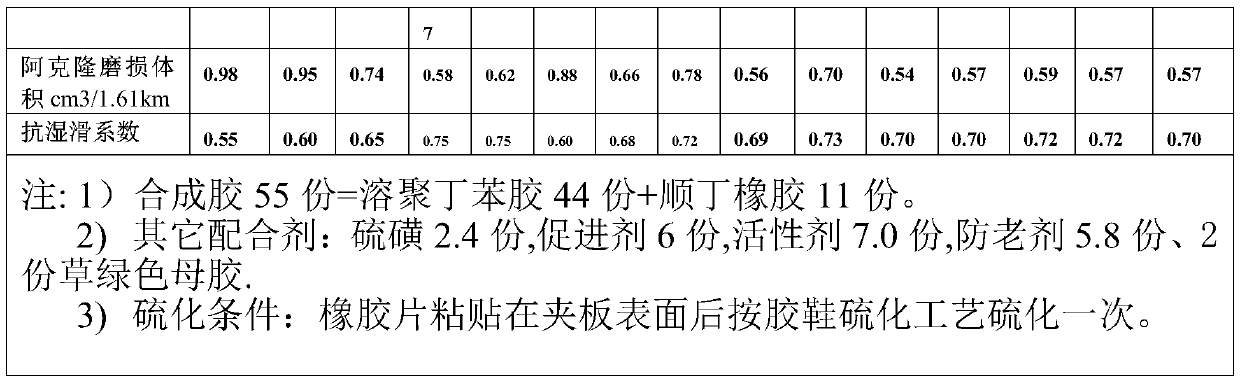

Examples

Embodiment 1

[0048] Embodiment 1 of the present invention: rubber shoes forming jig rubber, calculated in parts by weight, it consists of 45 parts of 1# standard rubber, 44 parts of solution polystyrene butadiene rubber, 11 parts of butadiene rubber, 2.4 parts of sulfur, 1.6 parts of accelerator DM , 1.1 parts of accelerator D and 1.1 parts of accelerator TMTD, 2.2 parts of entrapment agent CZ, 2.0 parts of stearic acid, 5 parts of nano-zinc oxide, 7.8 parts of polyethylene glycol, 5.8 parts of anti-aging agent, 4.5 parts of homogenized tear resistance Cracking agent, 45 parts of white carbon black, 4 parts of rubber lubricating oil, 11 parts of wear-resistant agent, 0.5 part of salicylic acid, 2 parts of grass green masterbatch.

[0049] The preparation method of rubber shoe forming jig rubber,

[0050]It is characterized in that: (1) To make plasticized rubber, put 40-50 parts of 1# standard rubber into the internal mixer, press the roller for 3-5 minutes, and then flatten the reel to ob...

Embodiment 2

[0051] Embodiment 2 of the present invention: rubber shoes molding jig rubber, calculated in parts by weight, it consists of 48 parts of 1# standard rubber, 41 parts of solution polystyrene butadiene rubber, 11 parts of butadiene rubber, 2.3 parts of sulfur, 1.5 parts of accelerator DM , 1.0 parts of accelerator D and 1.1 parts of accelerator TMTD, 2.2 parts of entrapment agent CZ, 2.0 parts of stearic acid, 5 parts of nano-zinc oxide, 7.8 parts of polyethylene glycol, 5.8 parts of anti-aging agent, 4.0 parts of homogenized tear resistance Cracking agent, 45 parts of white carbon black, 4 parts of rubber lubricating oil, 10 parts of wear-resistant agent, 0.5 part of salicylic acid, 1.5 parts of grass green masterbatch.

[0052] The preparation method of the jig rubber for rubber shoes molding is the same as in Example 1.

Embodiment 3

[0053] Embodiment 3 of the present invention: rubber shoes forming jig rubber, calculated in parts by weight, it consists of 42 parts of 1# standard rubber, 44 parts of solution polystyrene butadiene rubber, 14 parts of butadiene rubber, 2.4 parts of sulfur, 1.6 parts of accelerator DM , 1.1 parts of accelerator D and 1.1 parts of accelerator TMTD, 2.2 parts of entrapment agent CZ, 2.0 parts of stearic acid, 5 parts of nano-zinc oxide, 8 parts of polyethylene glycol, 5.8 parts of anti-aging agent, 4.6 parts of homogenized tear resistance Cracking agent, 45 parts of white carbon black, 3 parts of rubber lubricating oil, 12 parts of wear-resistant agent, 0.6 part of salicylic acid, 2 parts of grass green masterbatch.

[0054] The preparation method of rubber shoes forming jig rubber is the same as that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com