Novel hydraulic lifting appliance

A technology of hydraulic lifting and hydraulic lifting rod, which is applied to mechanical equipment, lifting devices, fluid pressure actuating devices, etc., can solve the problems of poor stability, limited lifting weight, and inability to realize the first separation of the double nets, and achieve stable operation, The effect of automatically maintaining the desired height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

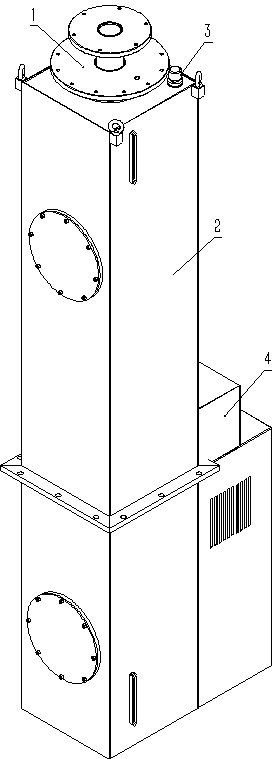

[0028] Embodiment 1: A kind of novel hydraulic lifting equipment (referring to figure 1 , see figure 2 , image 3 ,), which includes hydraulic lifting rod 1, hydraulic system 2, laser range finder 3, electric control box 4. The hydraulic system 2 is provided with a hydraulic lifting rod 1, and the hydraulic system 2 is provided with a laser rangefinder 3 and an electric control box 4.

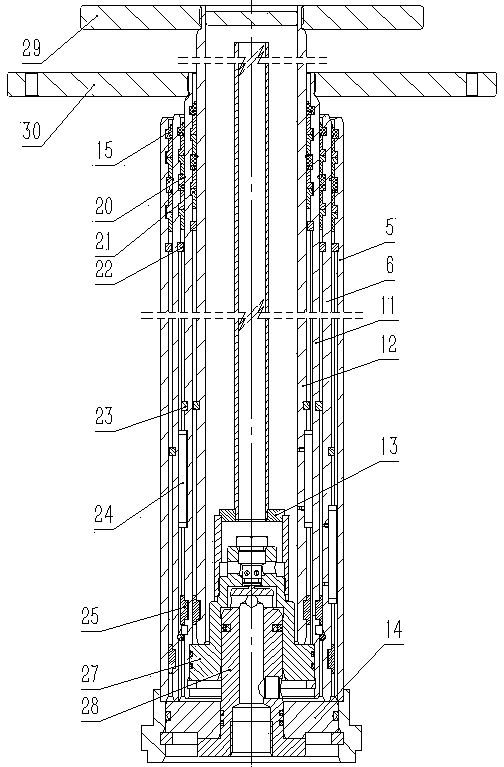

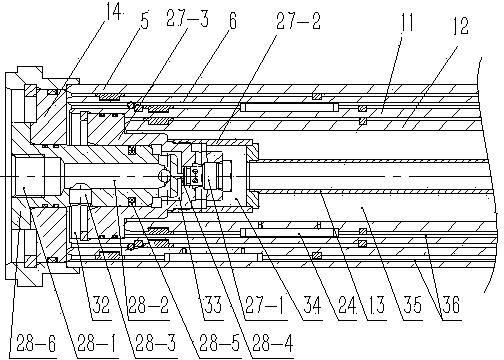

[0029]The present embodiment is three stages, which can rise 9 meters. The hydraulic lifting rod 1 includes a cylinder barrel 5, a primary piston rod 6 is arranged in the cylinder barrel 5, a secondary piston rod 11 is arranged in the primary piston rod 6, and a secondary piston rod 11 is arranged in the primary piston rod 6. 11 is provided with the innermost piston rod 12, the innermost piston rod 12 is provided with an exhaust pipe 13, a first-level sealing assembly 15 is arranged between the cylinder barrel 5 and the first-level piston rod 6, and the first-level piston rod 6 and A second...

Embodiment 2

[0037] Embodiment 2: A kind of novel hydraulic lifting equipment (see figure 1 , Figure 4 , Figure 5 ,) The hydraulic lifting rod in this embodiment has seven stages, which can rise 18 meters. Its structure and principle are basically the same as in Embodiment 1. 7. Three-stage piston rod 8, four-stage piston rod 9, five-stage piston rod 10, one-stage piston rod 6 is provided with two-stage piston rod 7, two-stage piston rod 7 is provided with three-stage piston rod 8, three-stage The piston rod 8 is provided with a four-stage piston rod 9, the four-stage piston rod 9 is provided with a five-stage piston rod 10, the five-stage piston rod 10 is provided with a secondary piston rod 11, a primary piston rod 6 and a secondary piston rod 7 is provided with a secondary seal assembly 16, between the secondary piston rod 7 and the tertiary piston rod 8 is provided with a tertiary seal assembly 17, between the tertiary piston rod 8 and the fourth piston rod 9 there are four A seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com