A method for detecting the surface roughness of Octogen particles

A technology of octogen and particle surface, applied in the field of octogen, octogen particle surface roughness detection, to achieve the effect of non-contact testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

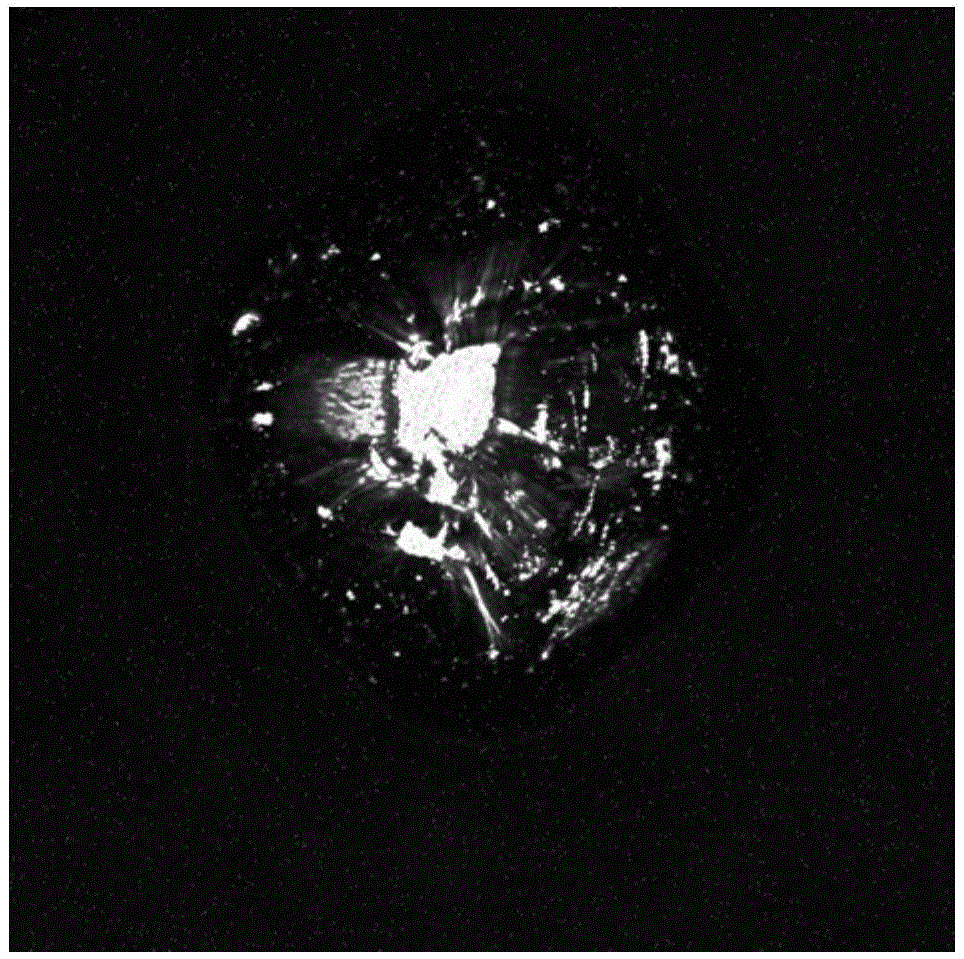

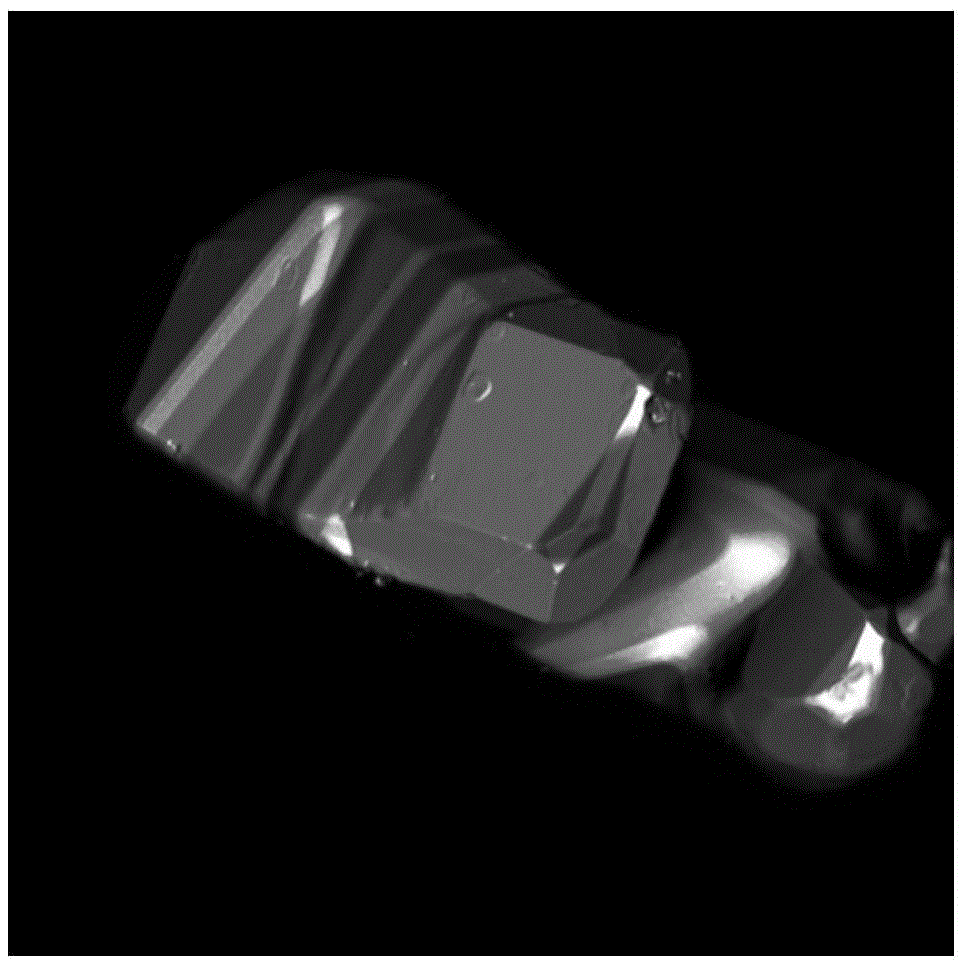

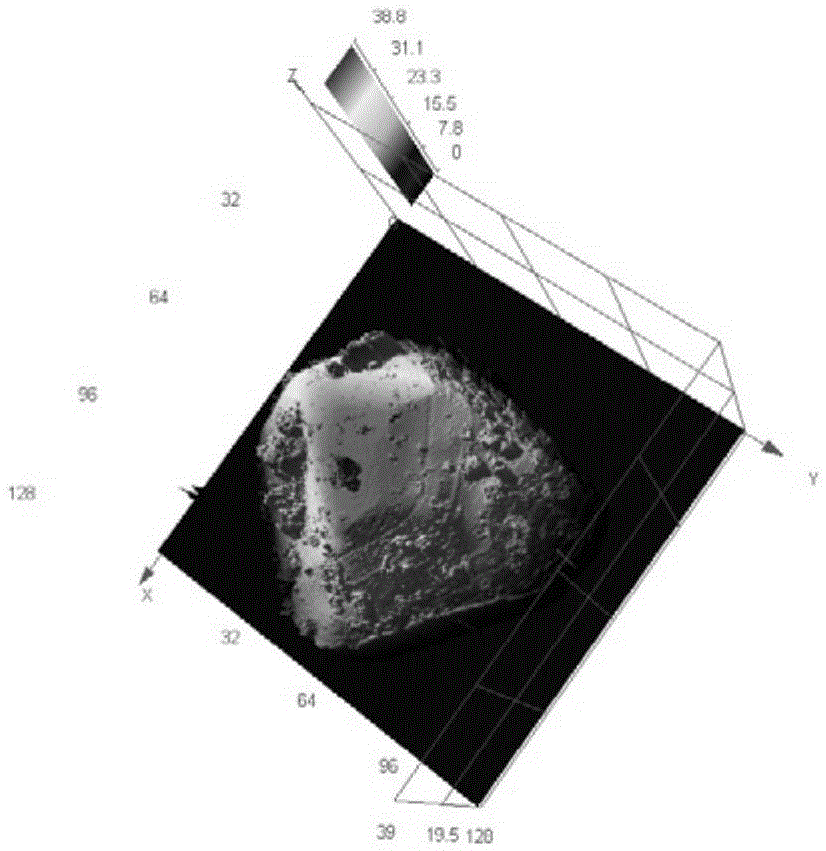

Image

Examples

Embodiment 1

[0058] The present embodiment provides a method for detecting the surface roughness of Octogen particles, the method comprising the following steps:

[0059] Step 1, refining the crude Octogen particles so that Octogen particles do not aggregate; the specific refining process is as follows:

[0060] At 25°C, under stirring, Octogen was added to DMSO in five equal parts, the mass ratio between Octogen and DMSO was 55:100, and Octogen was After it was completely dissolved, the temperature was lowered to -10°C, crystals were precipitated, filtered, and dried to obtain the refined Octogen.

[0061] Step 2, determine the number of samples to be tested that need to be drawn, and extract the samples to be tested according to the random number table:

[0062] Determine a sample of Octogen particles with a total of 562, and number each Octogen particle in the sample according to M>N 1 / 3 , where M is the number of samples to be tested, N is the total number of samples of Octojin sampl...

Embodiment 2

[0086] The present embodiment provides a method for detecting the surface roughness of Octogen particles, the method comprising the following steps:

[0087] Step 1, refining the crude Octogen particles so that Octogen particles do not aggregate; the specific refining process is as follows:

[0088] At 25°C, under stirring, Octogen was added to DMSO in five equal parts, the mass ratio between Octogen and DMSO was 55:100, and Octogen was After it was completely dissolved, the temperature was lowered to -10°C, crystals were precipitated, filtered, and dried to obtain the refined Octogen.

[0089] Step 2, determine the number of samples to be tested that need to be drawn, and extract the samples to be tested according to the random number table:

[0090] Determine a sample of Octogen particles with a total of 786, and number each Octogen particle in the sample according to M>N 1 / 3 , where M is the number of samples to be tested, N is the total number of samples of Octojin sampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com