A static automatic calibration system for eddy current sensors

An eddy current sensor, automatic calibration technology, applied in the direction of the instrument, can solve the problem that the distance between the sensor to be calibrated and the calibration plate cannot be guaranteed to be exactly zero, and achieve the effect of large bearing capacity, small system error and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

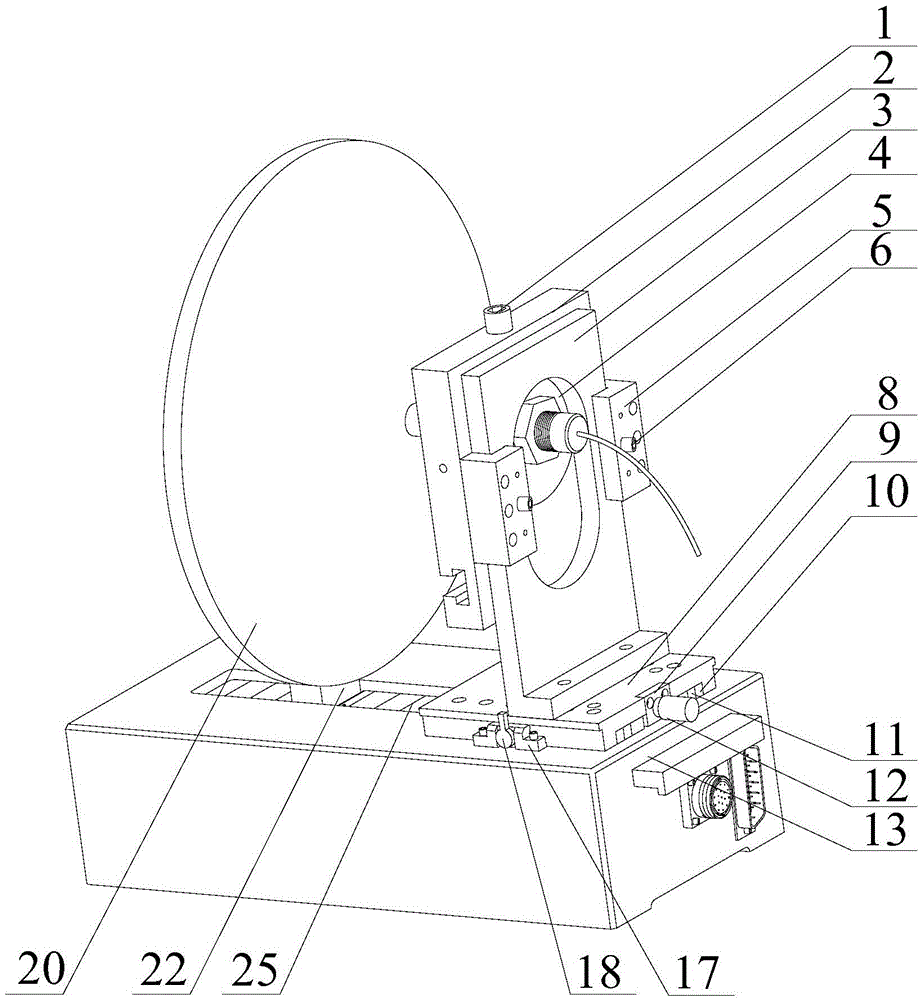

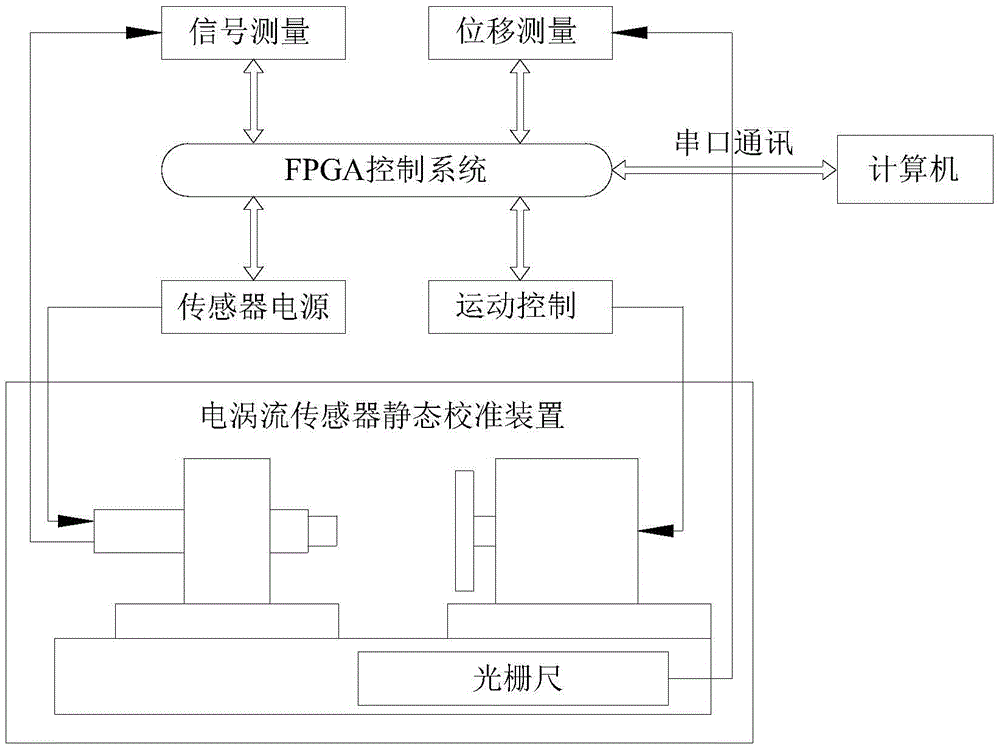

Method used

Image

Examples

Embodiment 2

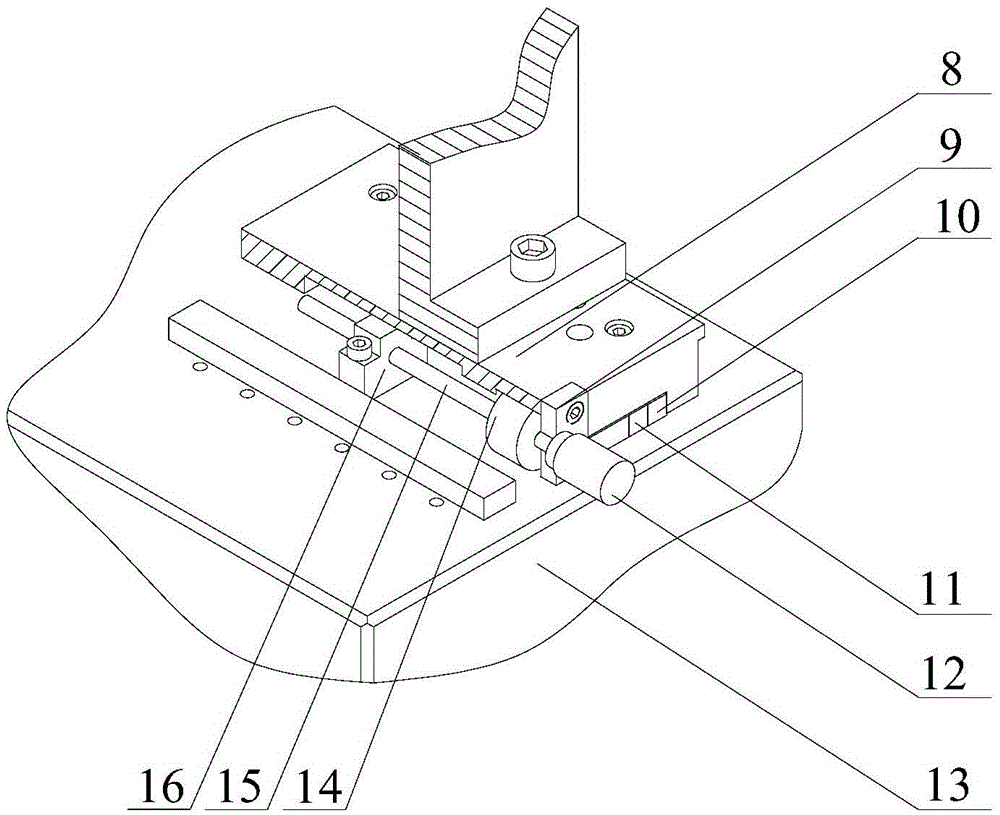

[0091] The difference between this embodiment and Embodiment 1 lies in that the specific structure of the constant torque knob is different. The structure except the constant torque knob is the same as that of Embodiment 1.

[0092] Such as Figure 7 As shown, the structure of the second constant torque knob is as follows: the constant torque knob 12 includes a connecting screw 12-1, a spring 12-2, a first ratchet 12-3, a second ratchet 12-4, and a knob body 12-5 And sleeve 12-6; Connecting screw 12-1 comprises the connecting shaft that is fixed with miniature screw rod 15, and the transmission shaft that is connected with first ratchet 12-3 and is positioned at the connecting block between connecting shaft and transmission shaft; First ratchet 12 -3 is slidably sleeved on the transmission shaft, and the transmission shaft is provided with a first limit block; the first ratchet 12-3 and the second ratchet 12-4 respectively include a gear tooth part and a sleeve part, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com