Special fixing wire grip for optical cable

A technology of cable puller and optical cable, which is applied in the direction of fiber mechanical structure, etc., can solve the problems of optical cable transmission loss, distortion, and optical cable can not be stretched too much, and achieve the effect of low product cost, simple product operation and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings

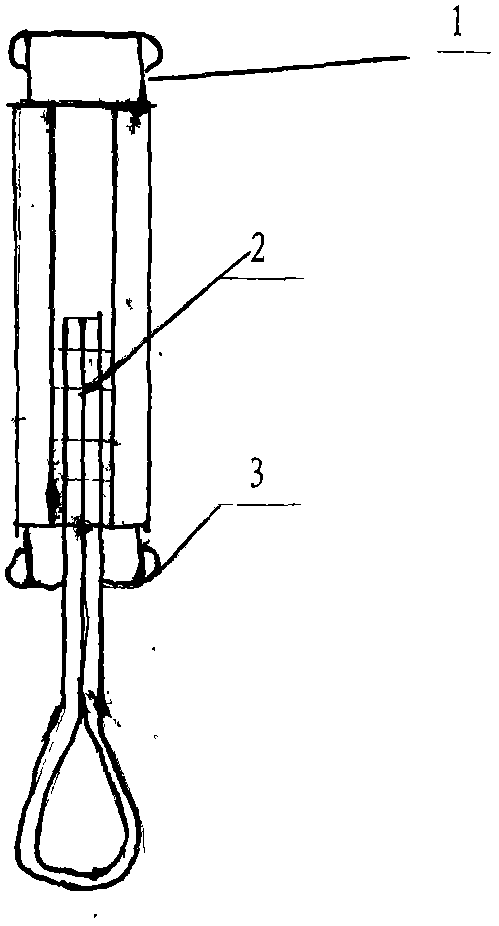

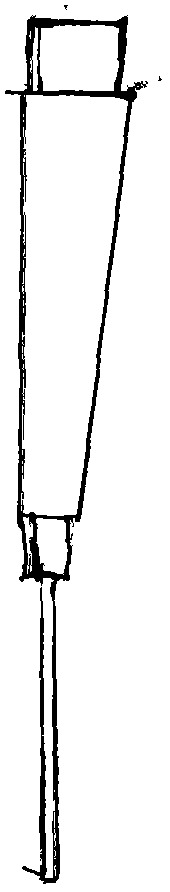

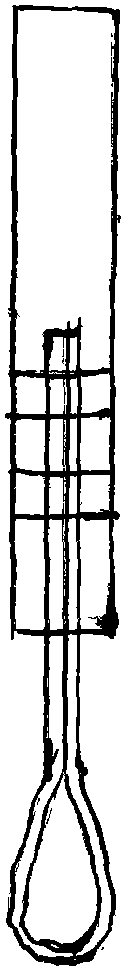

[0012] like figure 1 , figure 2 , image 3 , Figure 4 As shown in the figure, the special fixed wire puller for optical cables includes a fixed groove 1, a fixed rod 2, and an anti-skid pad 3. It is characterized in that: the anti-skid pad 3 is a concave-convex long strip structure, and the width of both ends is greater than the width of the bottom edge of the fixed groove 1. And in the fixing groove 1; the fixing groove 1 is a long U-shaped structure with one end high and the other low, and the upper edges of both sides are folded inward; the fixing rod 2 is penetrated by the high end of the fixing groove 1 and pulled out from the low end.

[0013] It should be understood that the above detailed description of the improved technical solution of the present invention by means of preferred examples is illustrative rather than restrictive. Those skilled in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap