Arc extinguishing chamber contact spring assembly for 12kV high-voltage ring main unit

A technology of arc extinguishing chamber and contact spring, applied in high-voltage air circuit breakers, high-voltage/high-current switches, electrical components, etc., can solve the problems of cumbersome assembly, inconvenient use, complex structure, etc., and achieve low manufacturing cost and consistent assembly Strong, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

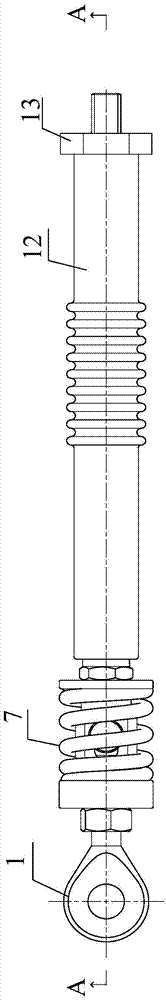

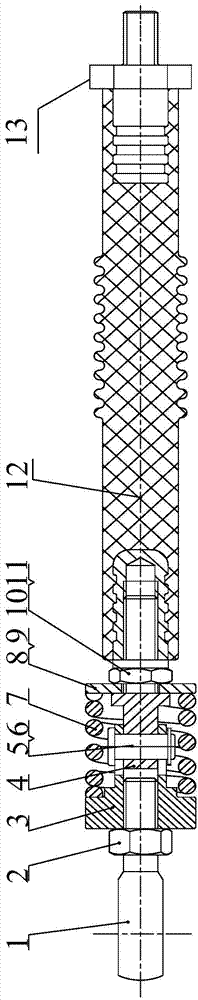

[0029] like figure 1 and 2 As shown, the contact spring assembly for the arc extinguishing chamber of the 12kV high-voltage ring network cabinet provided by the present invention sequentially includes: a rod end joint bearing 1, a hexagonal lock nut 2, a contact spring seat 3, a Contact spring seat connection block 4, another contact spring seat 8, a lock nut 10, an insulating pull rod 12, and an insulating pull rod insert 13; wherein, one end of the rod end joint bearing 1 is screwed on the contact One end of the spring seat, one end of the contact spring seat connecting block 4 is connected to the other end of the contact spring seat, and the other end of the contact spring seat connecting block passes through the contact spring seat 8 and locks in turn. The nut 10 is then inserted into one end of the insulating pull rod 12, and one end of the insulating pull rod insert 13 is inserted into the other end of the insulating pull rod 12. A shoulder is also formed on the contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com