Socket component and plug rod component of electric heating floor

A technology of electric heating floor and socket connection, which is applied in the direction of contact parts, electrical components, and parts of connecting devices, etc., and can solve the problems of easily damaged insulating skin of wires, unmentioned, burned floors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

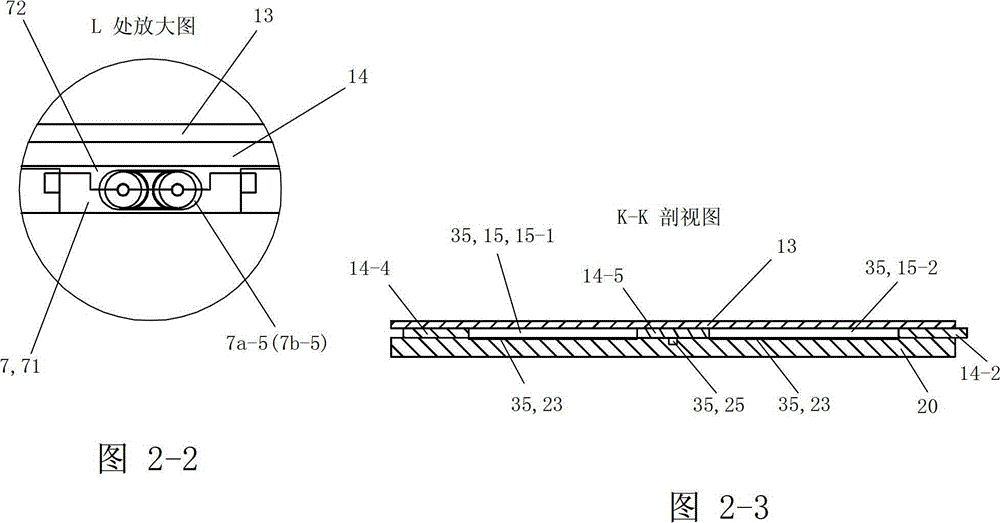

[0105] (Example 1, the socket component of the electric heating floor)

[0106] See Figure 8 , 12 and Figure 14 , The socket component of the electric heating floor of the present invention includes a socket 7, two conductive connectors 60 and two wires 62. The socket 7 includes a first insertion hole 7a-1, a second insertion hole 7a-2, a first pin hole 7a-3, a second pin hole 7a-4, a rear cavity and a wire hole; a wire hole The opening is backward and communicates with the rear cavity.

[0107] Both the first insertion hole 7a-1 and the second insertion hole 7a-2 open forward, and are arranged on the left and right sides; The pin hole sections are smoothly connected front and back; the pin hole sections of the first socket hole 7a-1 and the second socket hole 7a-2 are cylindrical, and the first socket hole 7a-1 and the second socket hole The guide hole sections of 7a-2 are basically in the shape of a truncated cone with a large front and a small rear, and the front sec...

Embodiment 2

[0141] (Example 2, the socket component of the electric heating floor)

[0142] The rest of this embodiment is the same as that of Embodiment 1, except that the socket 7 of this embodiment is an injection-molded integral part with an insert. The corresponding parts of the two conductive connectors 60 and the two wires 62 are integrated with the socket 7 as inserts when the socket 7 is injected.

Embodiment 3

[0143] (Embodiment 3, a plug rod member used for electrical connection of adjacent electric heating floors)

[0144] See Figure 17 to Figure 19, the plug rod member used for electrical connection of adjacent electric heating floors in the present invention includes a plug rod 81 and an electrical connector 83 . The plunger 81 is an injection molded one-piece piece with an insert. The plunger 81 is a position that can be waterproofly plugged and matched with the corresponding socket 7 of the corresponding phase-change heat storage type electric heating floor during use. The circumferential outer portions of the front and rear ends of the plunger 81 are composed of a plurality of truncated cone-shaped ring-shaped outer parts that decrease successively from the inside to the outside on the axis.

[0145] The electrical connector 83 is a copper integrated piece made of copper sheets, consisting of a copper sleeve 83-1 coaxial at the front and rear ends and a strip copper sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com