A three-cone drill bit for horizontal wells and hard formation wells

一种硬地层、水平井的技术,应用在钻头、钻管、钻杆等方向,能够解决加速牙齿磨损和断裂、井底岩屑排除不畅、磨损等问题,达到提高有效使用寿命、有利于钻井效率、使用寿命提高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in further detail below in conjunction with the drawings.

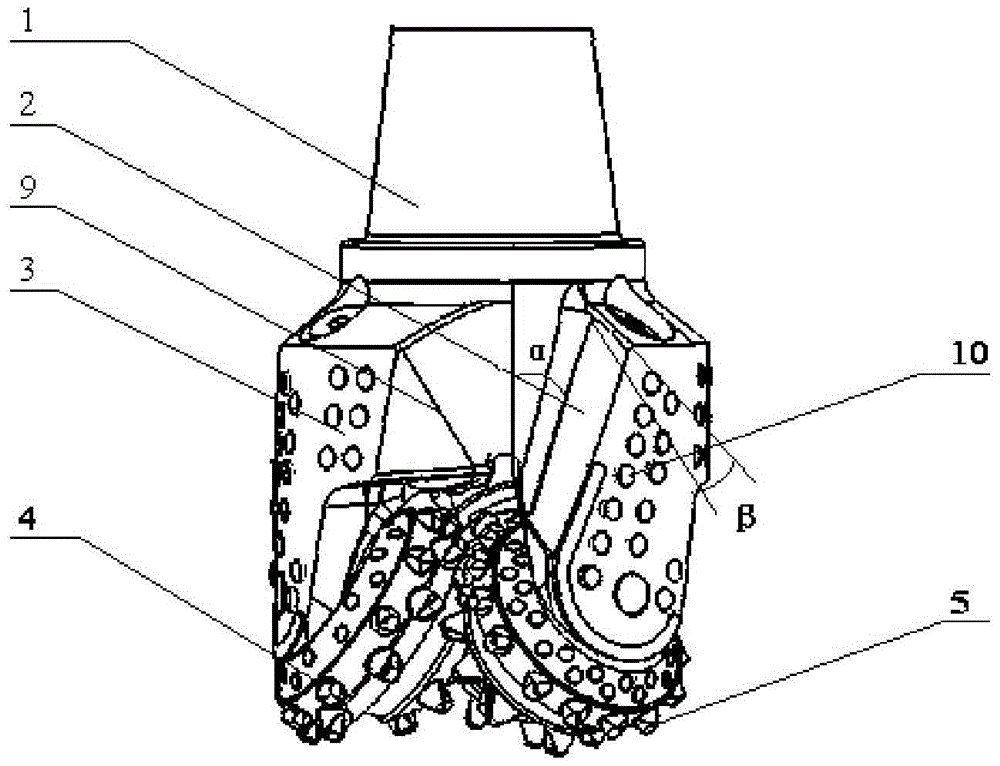

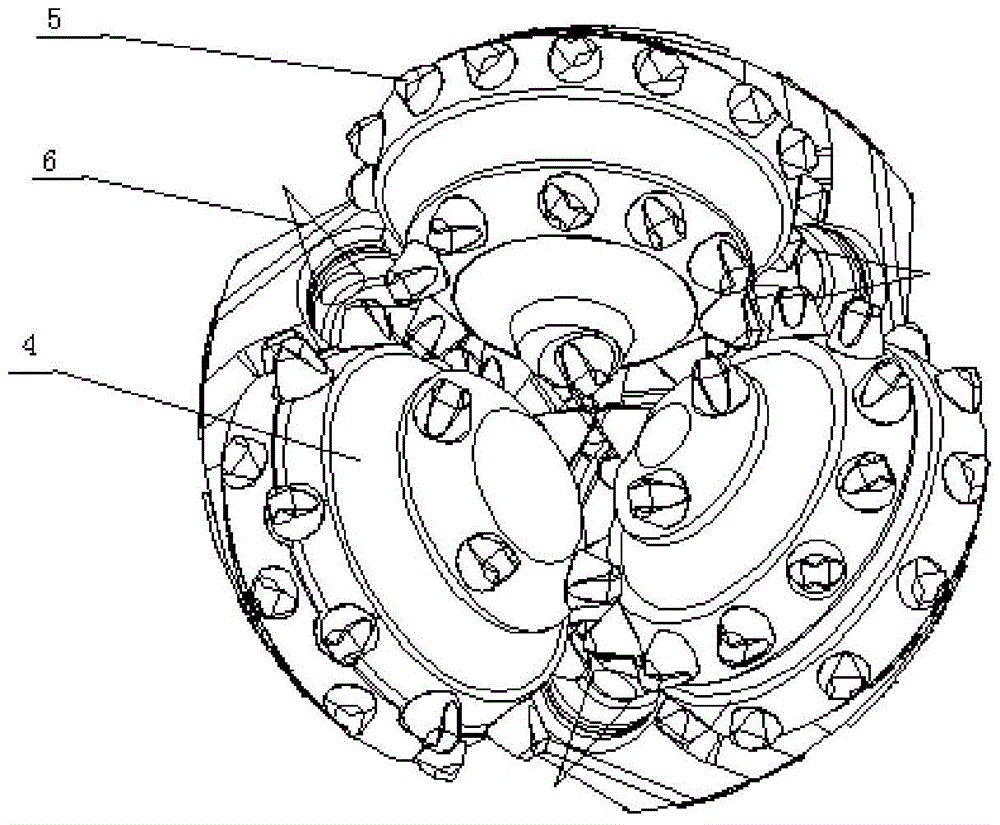

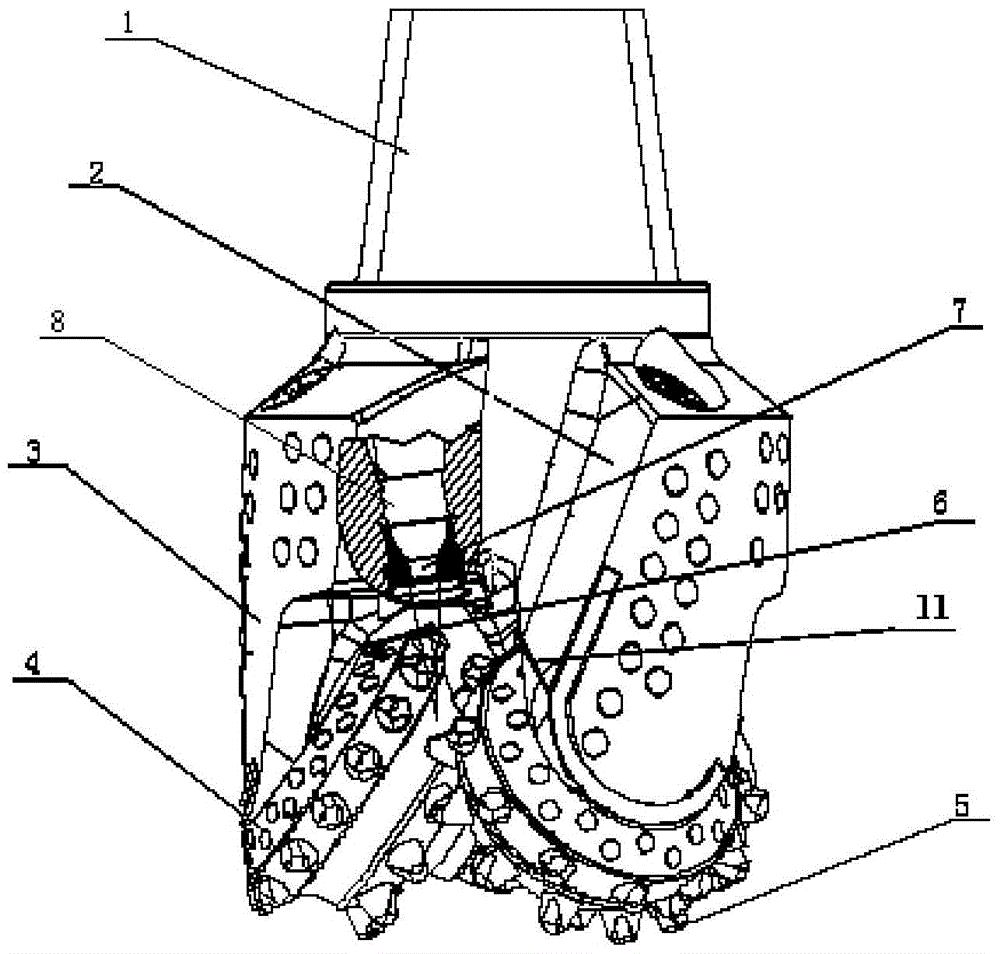

[0025] The first example Figure 1 to 3 As shown, it is a tri-cone drill bit, including three palms 3 and a cone 4 installed at the lower end of the palms. The upper parts of the three palms are connected by group welding to form a bit body. The upper part of the bit body is arranged There is a taper thread 1 to connect with the drill rod; extend a distance backward on the upper back side of the palm dorsum to form a rearwardly extending palm part, and install gage teeth on the rearwardly extending palm dorsal position, The gauge teeth are inlaid on the back of the palm, and can be arranged in 2 to 3 rows front and back, each row of 2 to 3 gauge teeth, which can be arranged at intervals and staggered. The gauge teeth are diamond composite teeth or cemented carbide teeth, forming The gauging surface of the upper part of the palm can also be inlaid with 2 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com