Automatic capturing detection device for circuit boards and detection method

A detection method and detection equipment technology, applied in the mechanical field, can solve problems such as low detection efficiency, missed detection, and tilt, and achieve the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

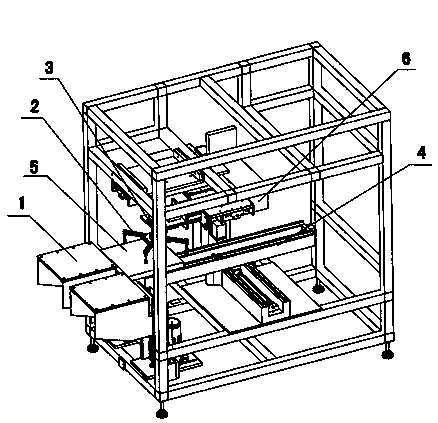

[0025] The invention discloses an automatic grasping detection device and a detection method for a circuit board. The detection device is as follows: figure 1 Shown includes a moving plate 5 for placing circuit boards and carrying out transport movement, said moving plate 5 being arranged on the guide rail 4 .

[0026] The grasping unit 2 used for grasping the circuit board is arranged above the circuit board and driven by the movement of the cylinder shaft 3 to move horizontally. The grasping unit 2 is a suction plate or a suction claw, and the present invention figure 1 The gripping unit 2 used in is a suction claw. The suction plate is a porous one, and may have various types of structures.

[0027] The device also includes an image processing unit for processing CCD photographic pictures, a classification output unit for classifying and outputting circuit boards, and a marking unit (not shown in the figure). The signal input end of the image processing unit is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com