A laser cutting machine that can improve the splitting yield of LED chips

A technology of LED chip and laser cutting machine, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., and can solve problems such as difficult cleaning, large ablation area, and too deep cutting depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in more detail below with reference to the accompanying drawings and embodiments.

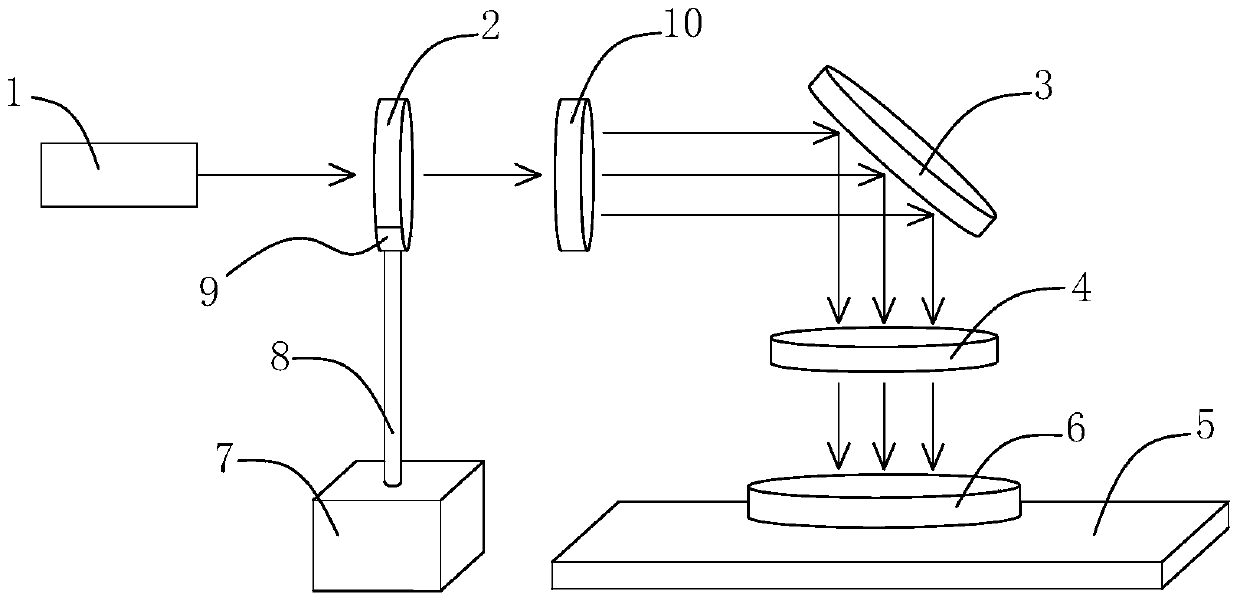

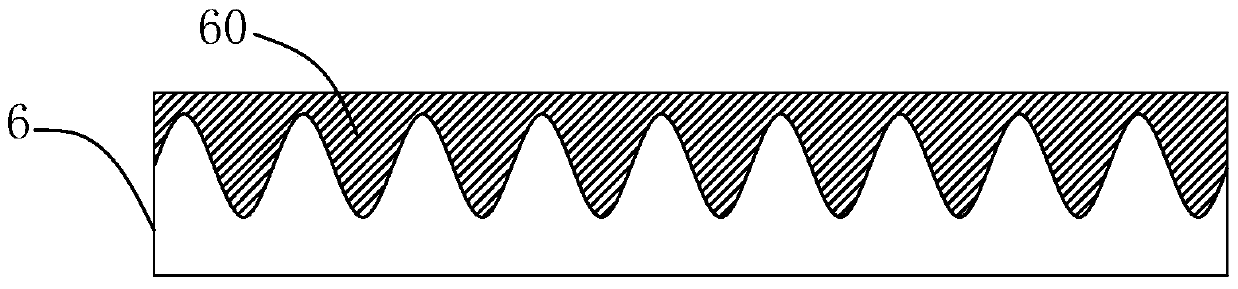

[0025] The invention discloses a laser cutting machine capable of improving the splitting yield of LED chips. Figure 1 to Figure 5 As shown, it includes a laser head 1 and a rotating mechanism 7, and along the laser transmission direction of the laser head 1 are sequentially provided with a 1 / 2 wave plate 2, a beam splitter 10, a reflector 3, a focusing mirror 4 and a moving stage 5, LED The chip 6 is placed on the moving stage 5, and the 1 / 2 wave plate 2 is arranged on the rotating mechanism 7. As a preferred method, the power output end of the rotating mechanism 7 is provided with a driving rod 8, and the end of the driving rod 8 is provided with a driving rod 8. There is a hollow bearing seat 9, the 1 / 2 wave plate 2 is fixed on the hollow bearing seat 9, and the rotating mechanism 7 drives the 1 / 2 wave plate 2 to rotate around the radial direct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com