Process chamber air distribution adjustment-oriented chemical vapor deposition (CVD) equipment spray header

A process chamber and shower head technology, applied in metal material coating process, gaseous chemical plating, coating, etc., can solve the problems of limited degree of process performance improvement, difficulty, large equipment modification, etc., to achieve high efficiency and fineness The effect of adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

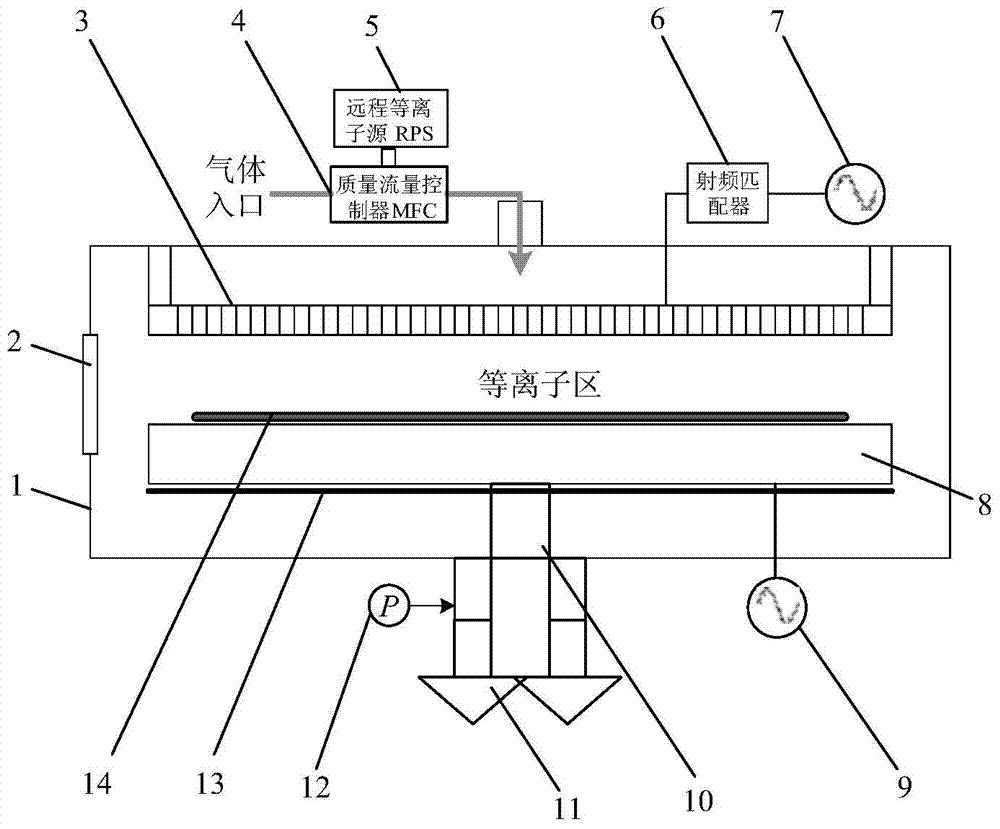

[0026] The present invention provides a CVD equipment shower head for adjusting the gas flow distribution of a process chamber. The present invention will be further described below in conjunction with the accompanying drawings and specific implementation methods.

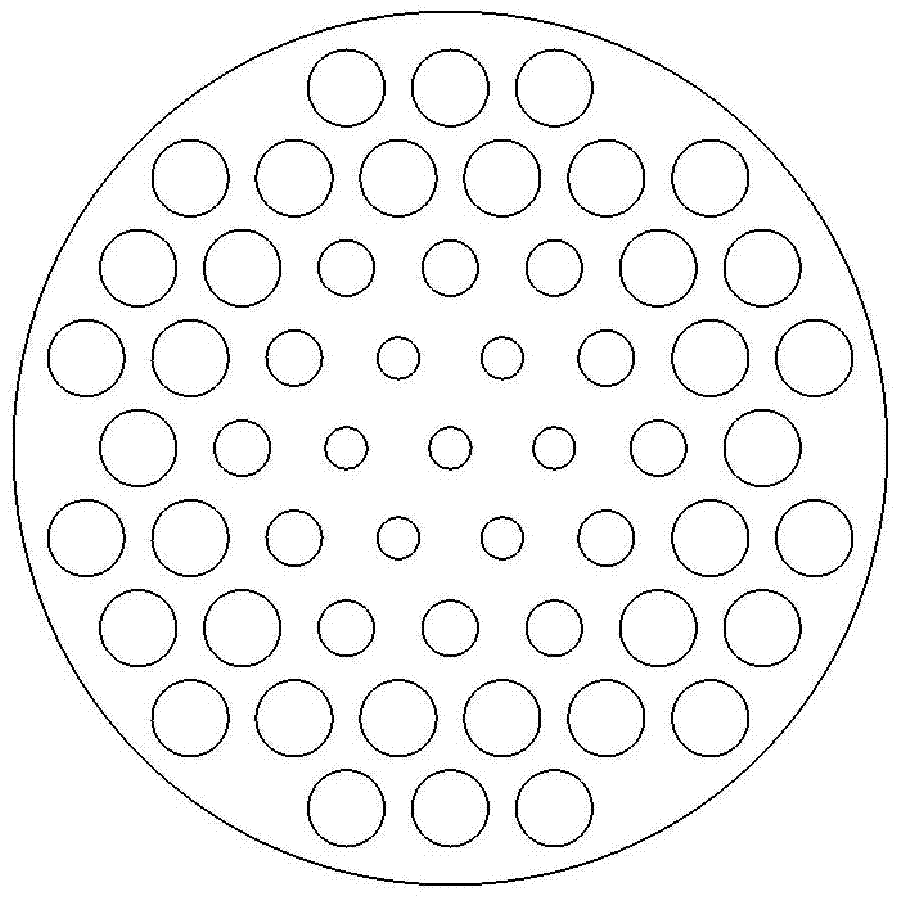

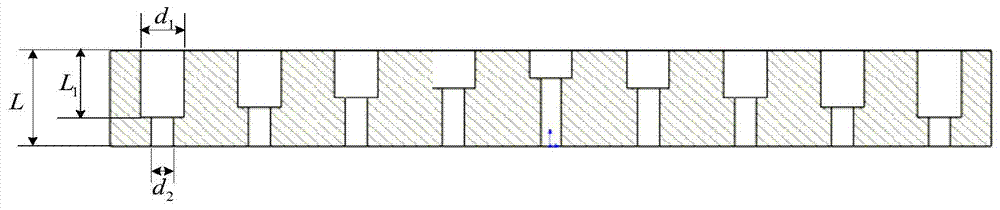

[0027] see figure 2 and image 3 The shower head 3 is provided with several step-shaped spray holes 31 arranged in a two-dimensional hexagonal array, and the spray holes 31 are composed of a large circular hole with a larger diameter at the upper part and a small circular hole with a smaller diameter at the lower part.

[0028] The spray holes 31 have the following layouts:

[0029] From the center to the edge of the shower head plate surface 14, the step depth of the spray hole 31 is kept the same, and the diameter of the large or small circular hole of the spray hole 31 gradually increases, thereby realizing the impedance of the shower head plate surface from the center to the edge. The edge is gradually reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com