Circular buckle plate mechanical pile splicing method for precast square piles

A technology of prefabricated pipe piles and concave-convex plates, which is applied in sheet pile walls, buildings, and foundation structure engineering, can solve problems affecting construction efficiency, reducing pile quality, and wasting time, so as to reduce potential safety hazards and reduce mechanical damage. The effect of connecting the dots and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail. The invention mainly aims at ensuring the integrity of the end plate structure for the prefabricated pipe pile, reducing connection points, reducing potential safety hazards and increasing the reliability of the structure.

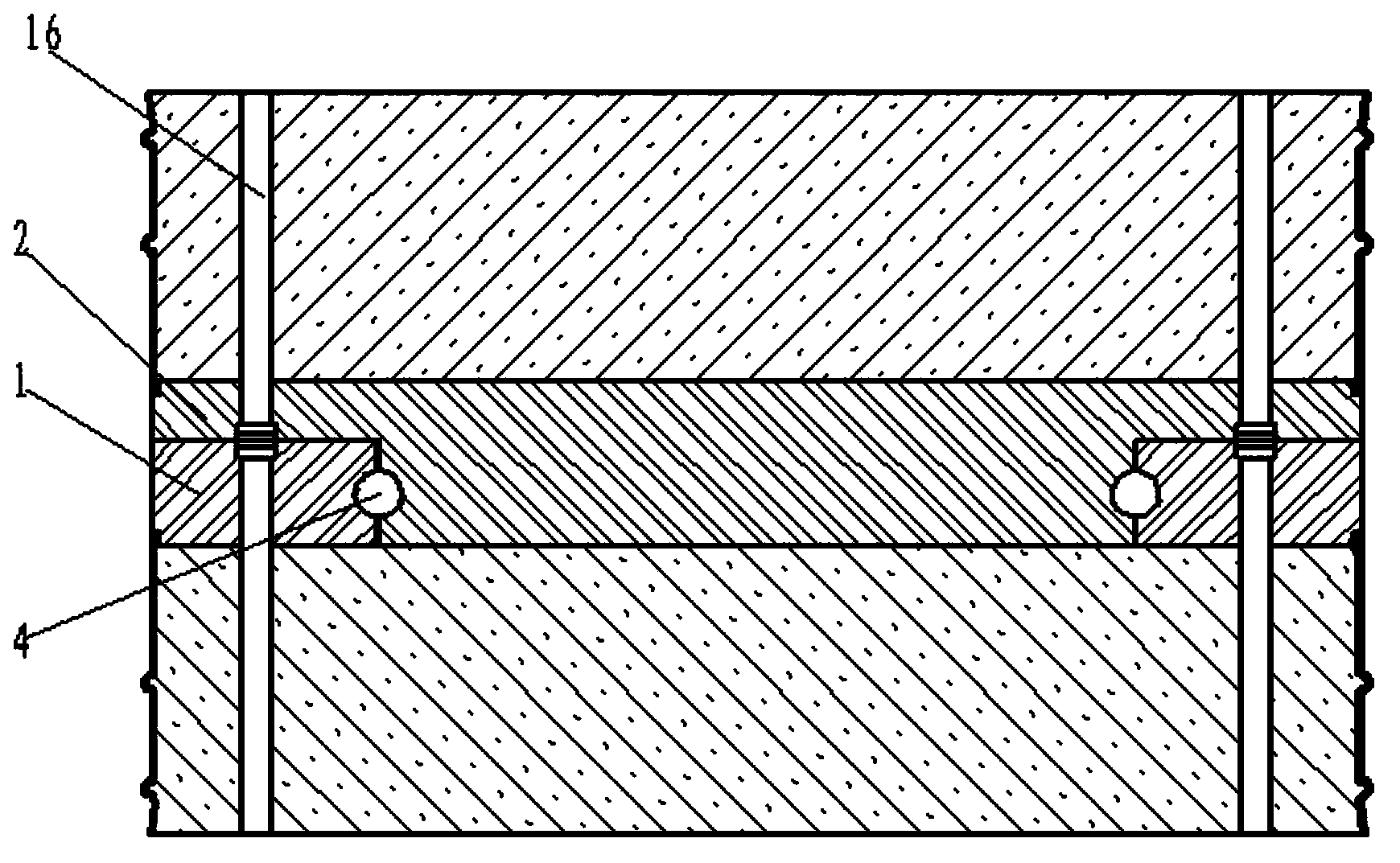

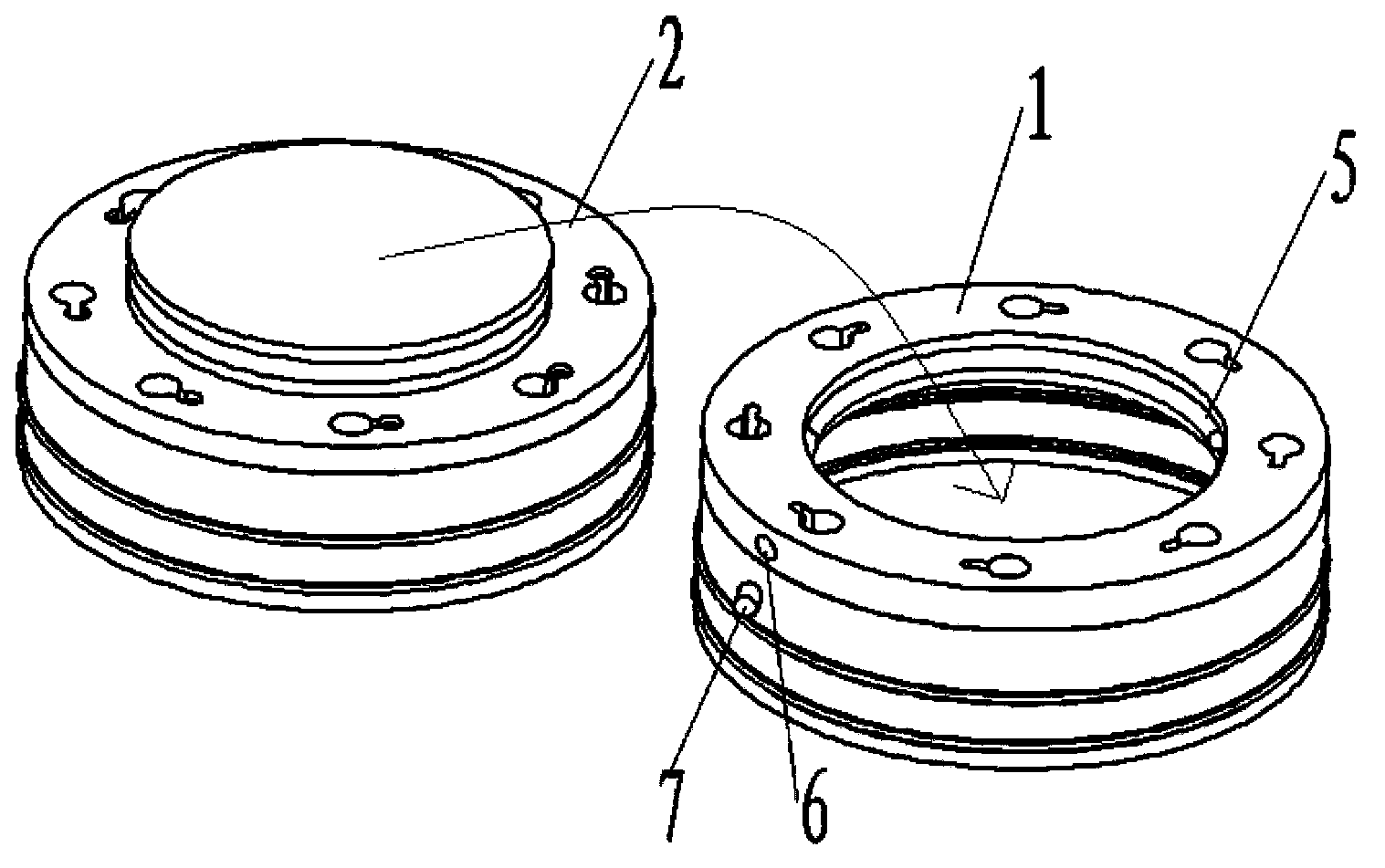

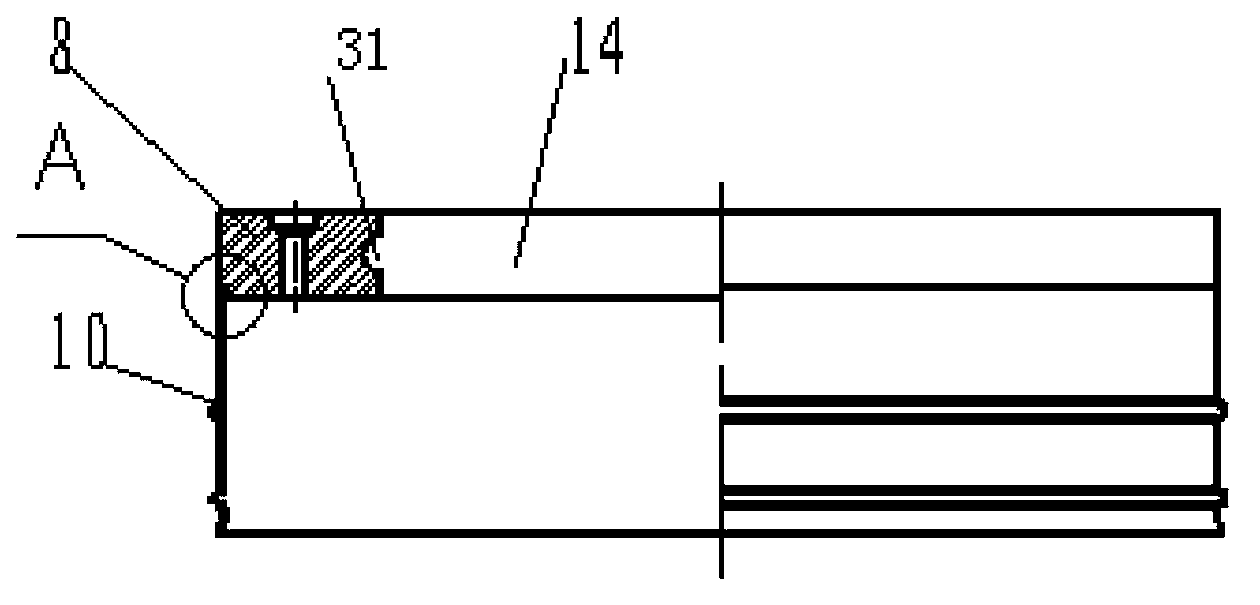

[0021] figure 1 It is a schematic diagram of connecting piles of the upper and lower section piles of the present invention. figure 2 It is a schematic diagram of the butt joint structure of an end plate with a circular groove and an end plate with a circular convex plate.

[0022] Such as Figure 1-2 As shown, the present invention adopts the end plate 1 with the circular groove and the end plate 2 with the circular convex plate to splice together, the end plate 2 with the circular convex plate and the end plate 2 with the circular groove The end plates 1 are resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com