Bearing cage with outer diameter groove and design method thereof

A bearing cage and design method technology, which is applied to bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of unstable bearing friction torque, easy whirl movement of the cage, and reduced bearing service life, and achieves the pass rate The effect of improving and reducing assembly and debugging time and increasing the guide clearance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Take the 618 / 3 bearing cage design as an example:

[0027] Cage outer diameter: φ6.5, guide clearance: 0.2±0.1mm, number of pockets: 6, bearing speed 6000rpm;

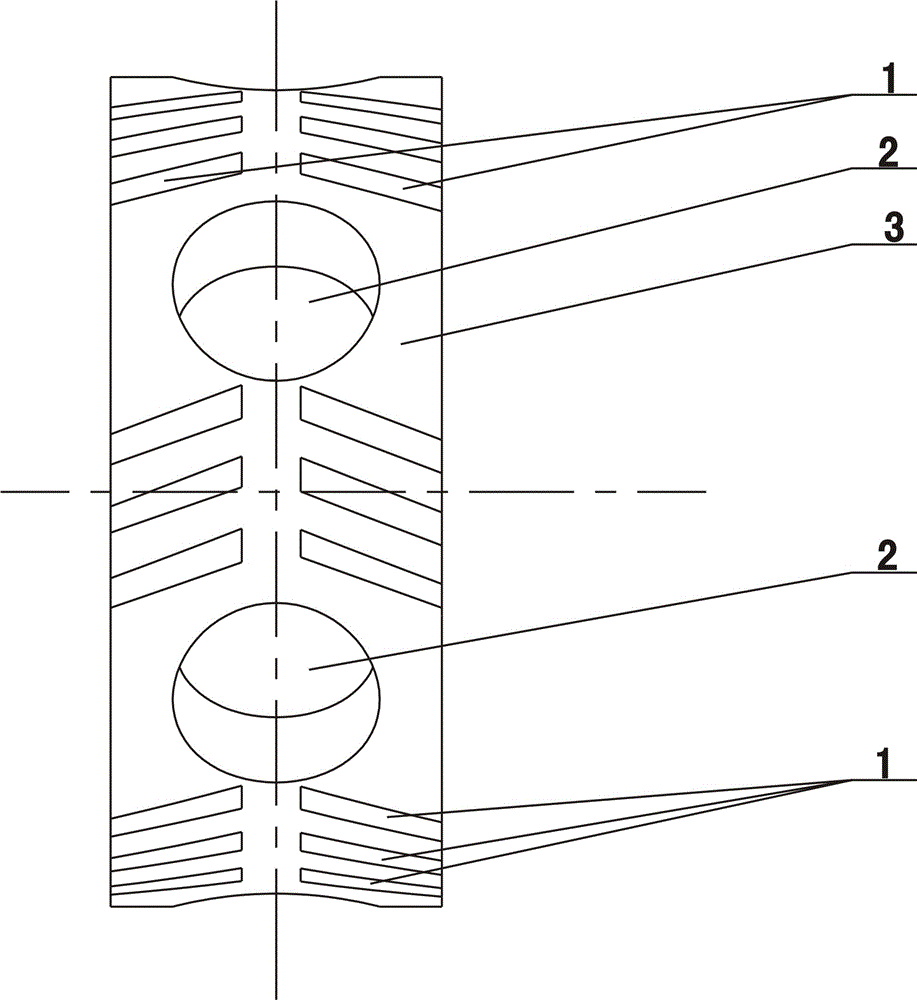

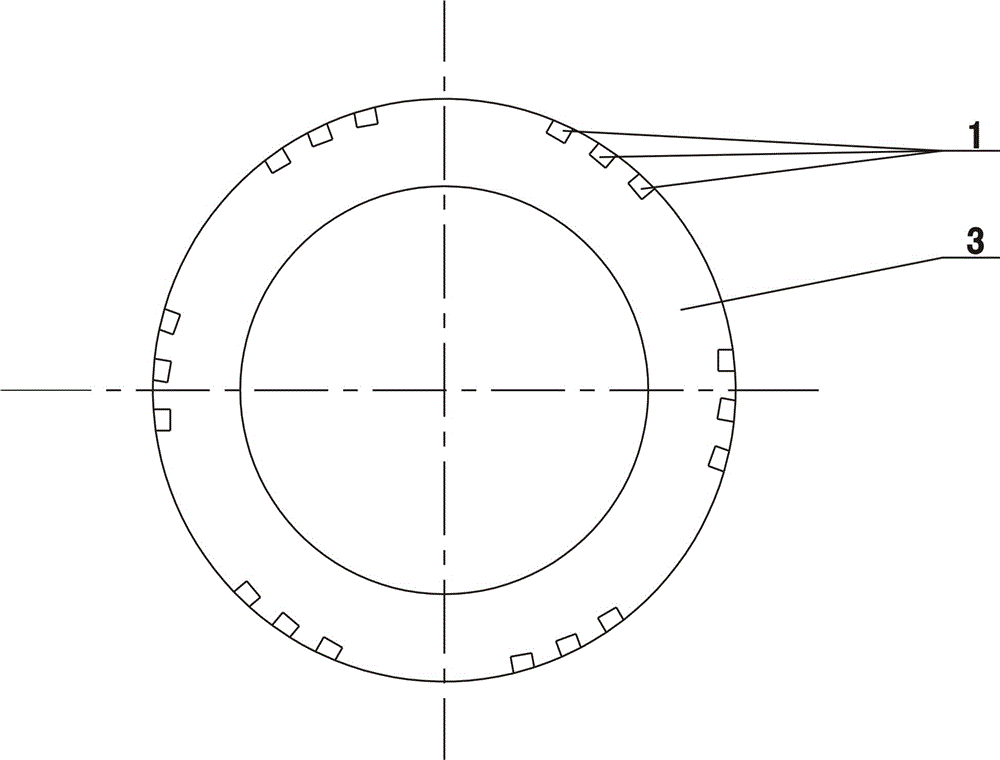

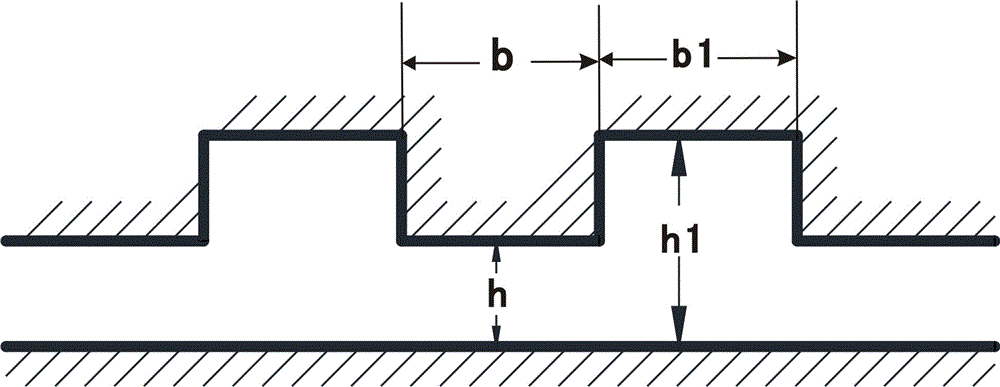

[0028] The outer diameter of the cage is designed with a herringbone chute, the slope of the groove is 18°, and the number of groove groups k is In order to ensure the balance of the cage, k adopts 6 sets of herringbone chute, considering that the bearing speed is medium speed, the groove depth h=0.6mm.

[0029] The bearing cage with outer diameter grooves and the design method thereof according to the present invention process a straight-groove-shaped herringbone groove on the outer diameter of the bearing cage, such a structure increases the range of the guide clearance for the bearing to keep the bearing running stably Large, which reduces the difficulty of bearing processing and manufacturing, and the stability of the cage is improved when the bearing is in operation. The bearing will not only produce no h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com