Negative pressure siphoning backflow vacuum valve

A vacuum valve and siphon technology, applied in valve details, control valves, valve devices, etc., can solve problems such as inability to open, complicated processing, and high price, and achieve the effects of high reliability, flexible cover plate, and large air supply volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

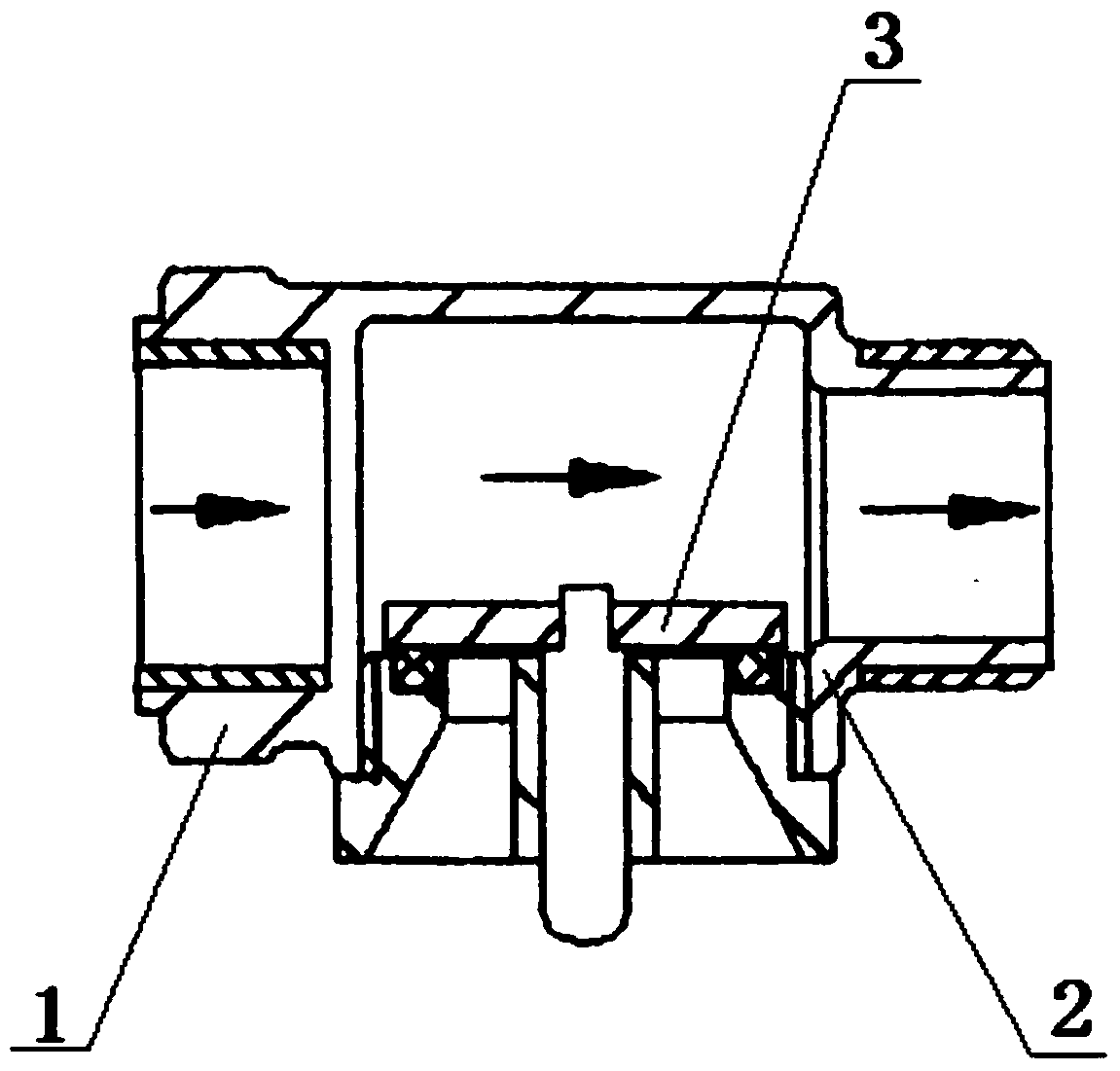

[0042] Specific implementation 1. The negative pressure siphon backflow vacuum valve has a length of 55 mm and a height of 41 mm.

Embodiment 2

[0043] Specific implementation 2, the negative pressure siphon backflow vacuum valve has a length of 76 mm and a height of 62 mm.

Embodiment 3

[0044] Specific implementation 3, the negative pressure siphon backflow vacuum valve has a length of 96mm and a height of 72mm.

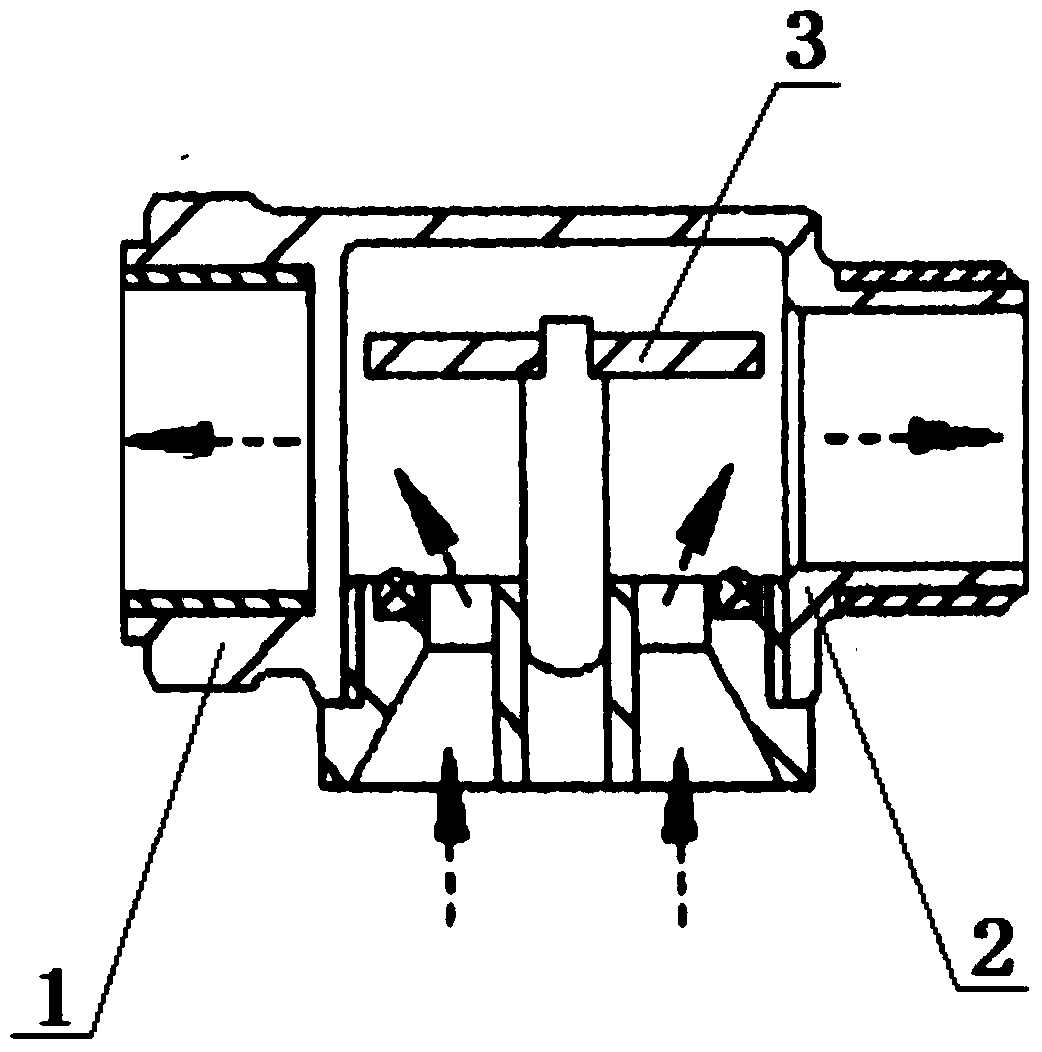

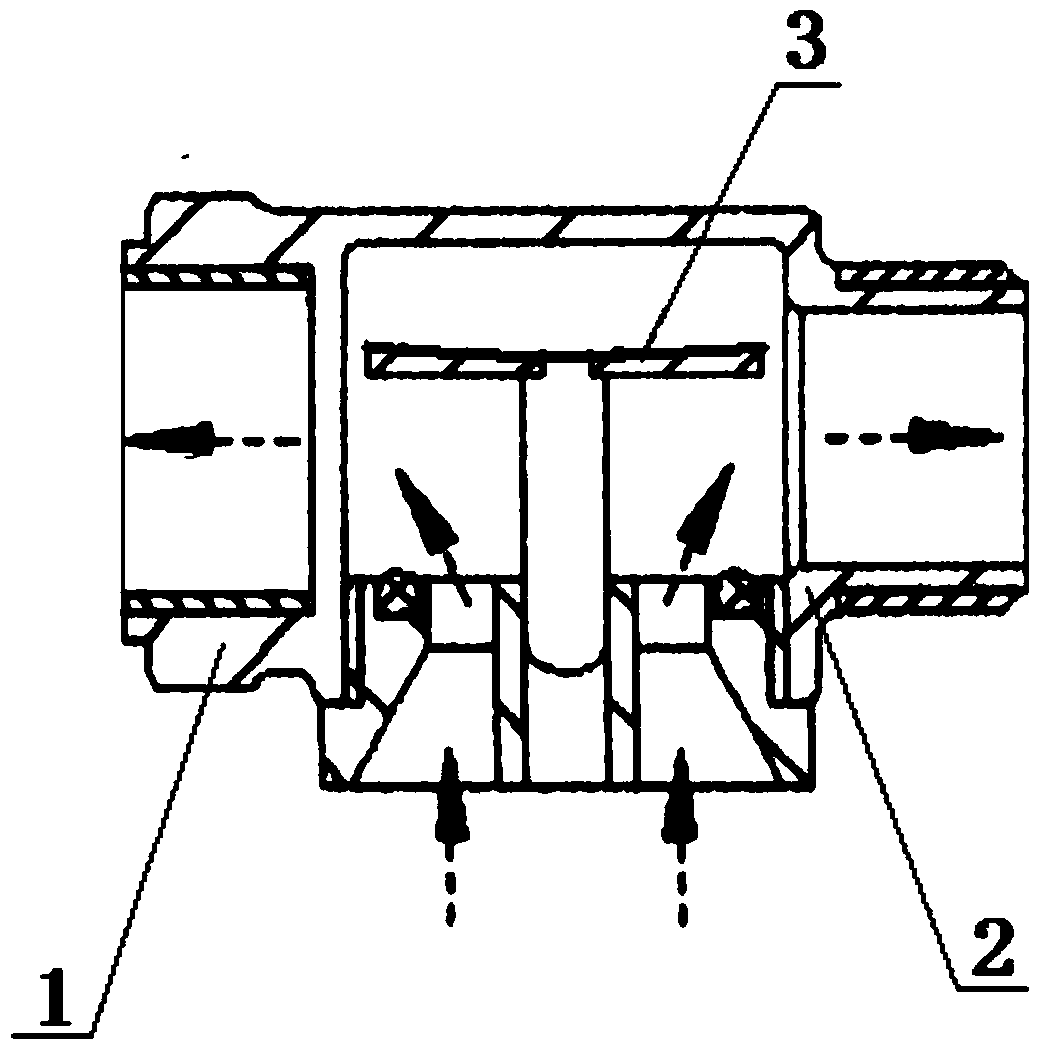

[0045]A piezoelectric ceramic is arranged between the valve body and the "T"-shaped cover plate, and the piezoelectric ceramic is connected to an indicator light through an electric energy storage unit. The indicator light is preferably led light. When the "T"-shaped cover plate presses down on the valve body, piezoelectric ceramics generate electricity and the indicator light is on. As a preferred solution, the vertical distance between the lower edge of the expansion port and the water outlet of the downstream pipeline is not less than 150 mm.

[0046] Beneficial effects: the present invention has high working safety and reliability, good sealing performance and no water leakage during normal use, flexible cover plate and large amount of air replenishment when replenishing air; no need for operation control, fully automatic work, using atmospheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com