Manual and electric automatic separating and combining mechanism of electric actuator

An electric actuator and automatic clutch technology, which is applied in the direction of engine components, mechanical equipment, valve operation/release devices, etc., can solve problems such as easy wear of the shaft sleeve, difficulty in movement, and influence on the conversion effect of the actuator.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

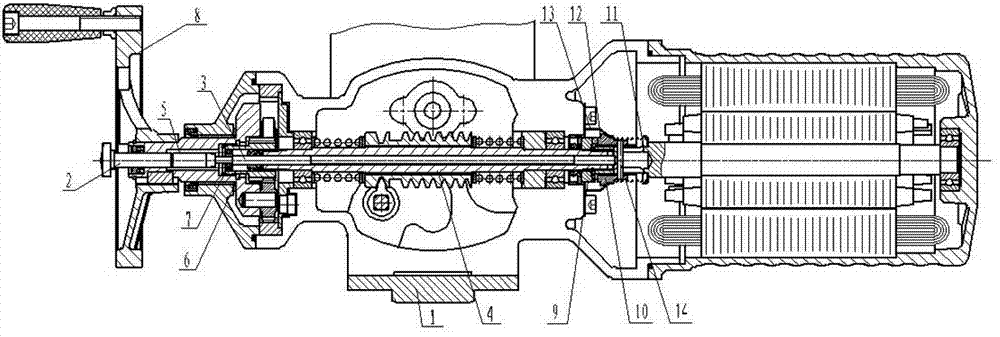

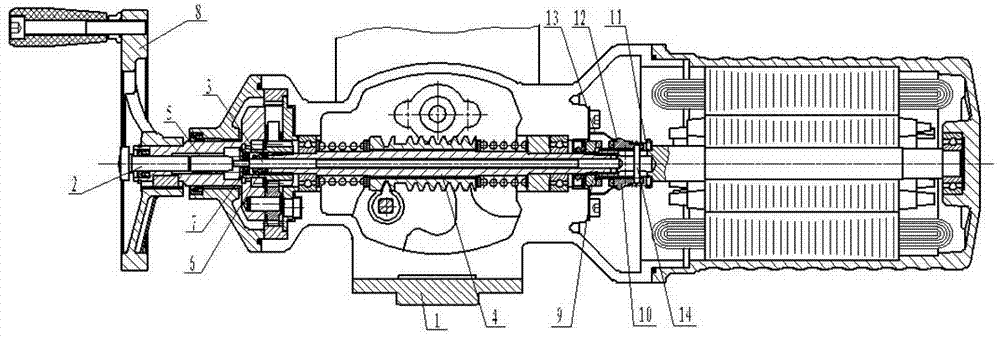

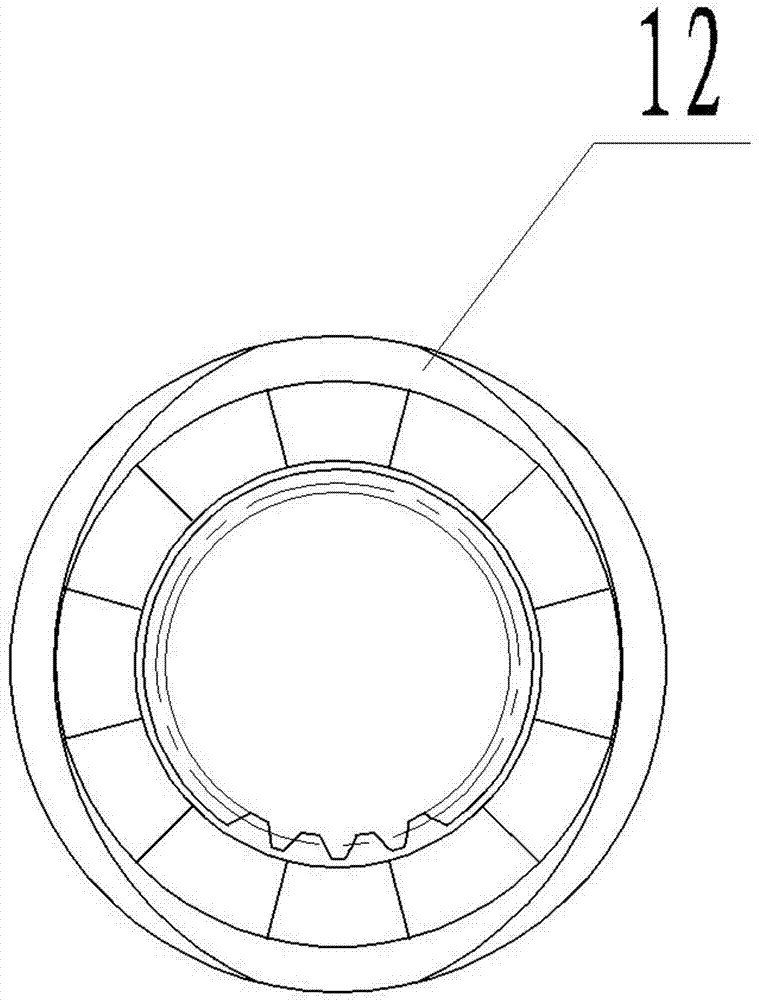

[0012] The accompanying drawings show the technical solution of the present invention and its embodiments, and the relevant details will be further described below in conjunction with the accompanying drawings. The manual and electric automatic clutch mechanism of the electric actuator includes a base 1, and the base 1 is equipped with Switching ejector rod 2, ejector rod 3, hollow shaft 4 and clutch, said switching ejector rod 2 is provided with a first elastic device 5, said first elastic device is a switching ejector rod return spring, pushing inwardly switching ejector rod 2 When switching the ejector rod 2, it will push the ejector rod 3 to move. To move, one end of the hollow shaft 4 is covered with a center wheel 6, and the hollow shaft 4 is engaged with the center wheel 6, that is, the hollow shaft 4 is provided with an external spline, and the center wheel 6 is provided with an internal spline. When the spline is engaged with the inner spline, the center wheel 6 can d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com