Adjustable gap nonlinear research test bed and use method thereof

A research experiment and nonlinear technology, which is applied in the field of test platform for studying the nonlinear effect of gaps and system parameter identification. Control and other issues, to achieve the effect of compact structure, guaranteed accuracy requirements, easy processing and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

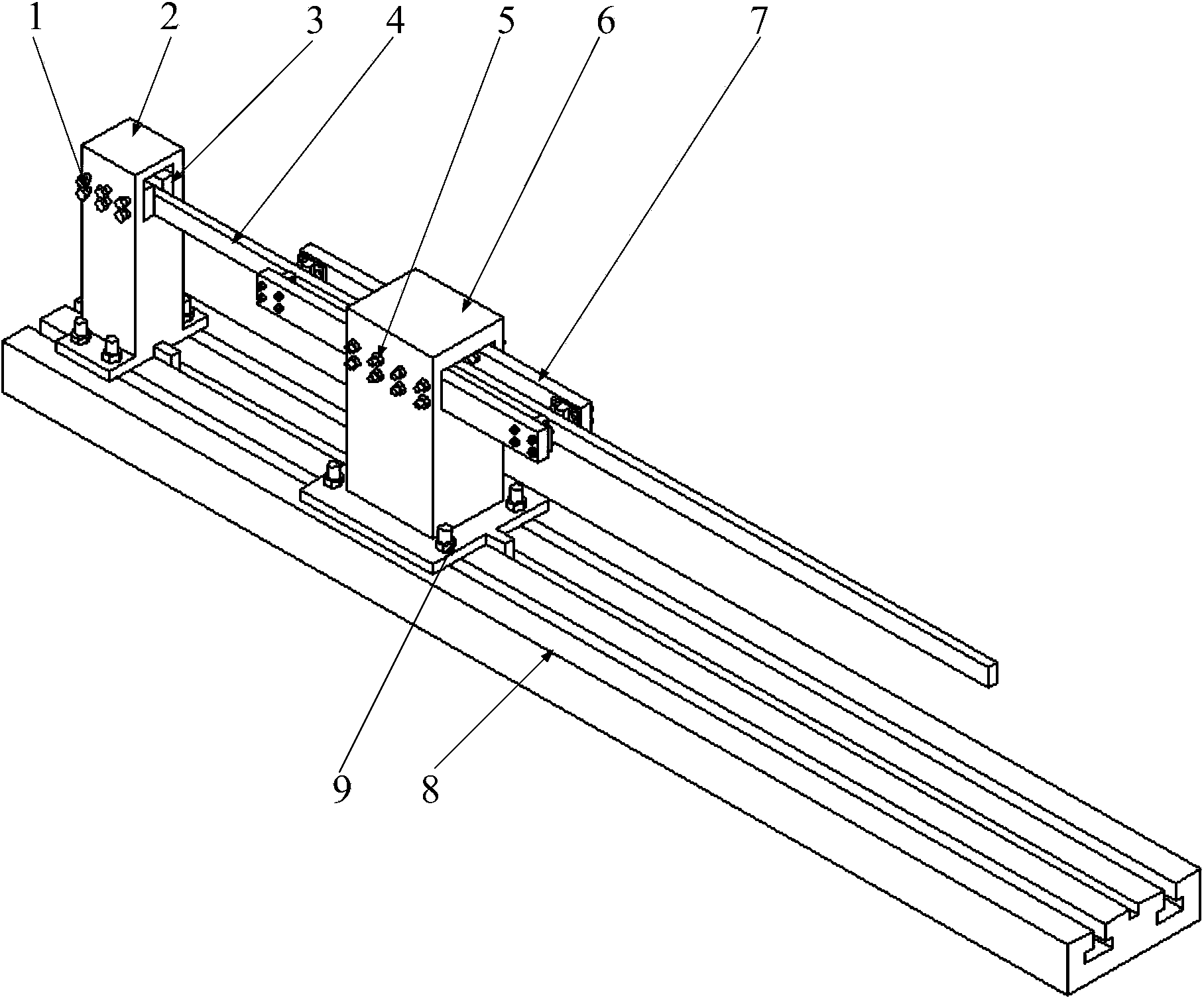

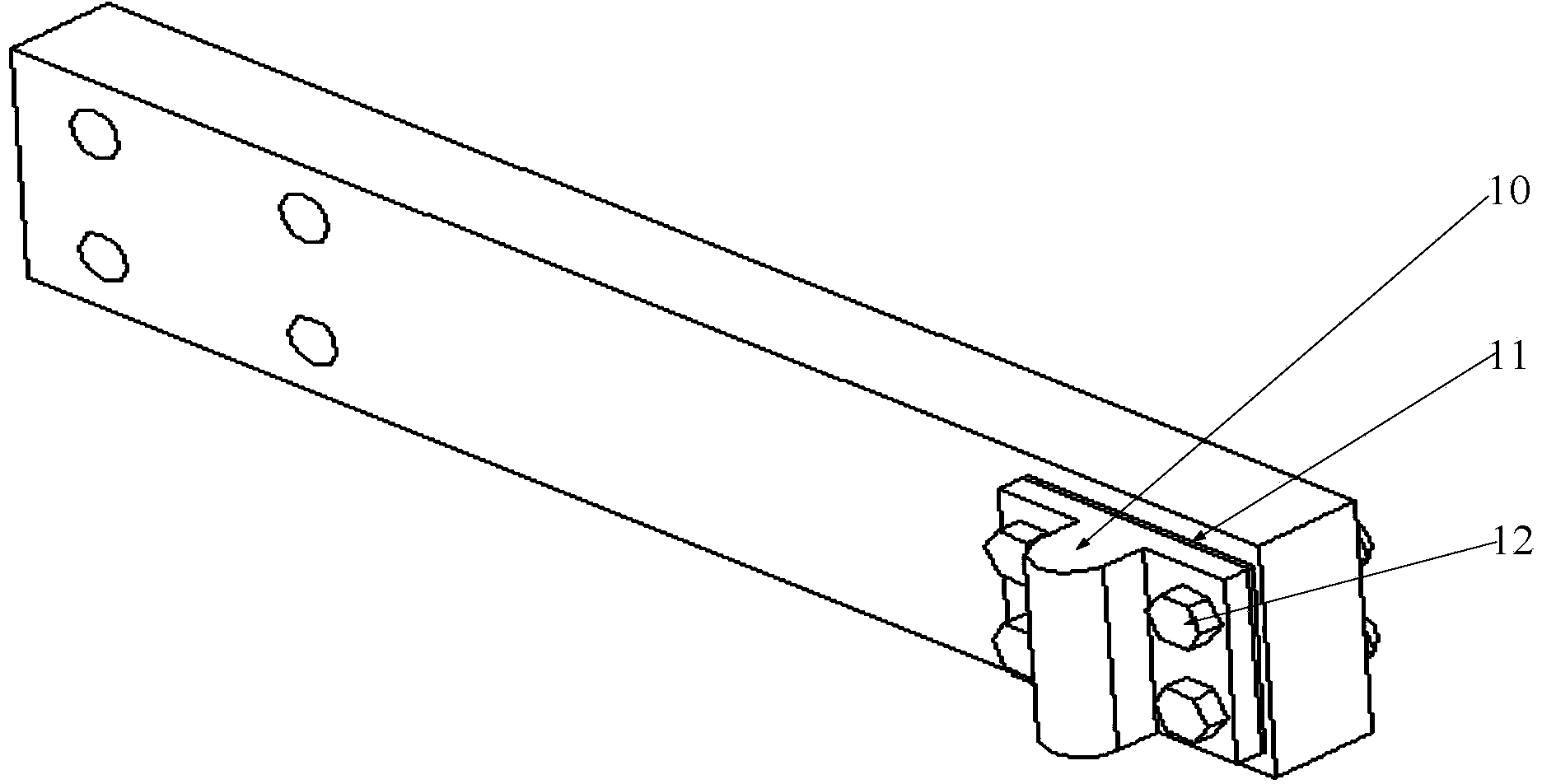

[0024] refer to figure 1 and figure 2 As shown, an adjustable gap nonlinear research test bench includes a cantilever beam 4, a gap size adjustment component, a gap stiffness adjustment component, a gap position adjustment component, a cantilever beam support component, a base 11, and the like. Through the gap parameter adjustment device, different positions, different sizes, different stiffnesses and different numbers of gaps are obtained, and the vibration characteristics of the cantilever beam under different gap conditions and the parameter identification of the system with gaps are studied.

[0025] Wherein the gap position adjustment assembly is made up of the gap position adjustment frame 9 and the base fastening bolt 12, the gap position adjustment frame 9 is fixed on the base 11 by the base fastening bolt 12, and the gap position adjustment frame 9 slides along the guide groove of the base 11. The adjustment of the gap position is realized; the gap stiffness adjustm...

Embodiment 2

[0029] A method for performing an adjustable gap measurement experiment using an adjustable gap nonlinear research test rig, comprising:

[0030] Step 1, the experimental parameter initialization step: including setting the initial positions of the cantilever beam support frame 2 and the gap position adjustment frame 9, setting the optional thickness of the gasket 7, and setting the external excitation source;

[0031] Step 2, test bench assembly step: set and fix the cantilever beam support frame 2 and the gap position adjustment frame 9 on the base 11 according to the initialization parameters determined in step 1; fasten the bolt 1 through the spacer 3 and the cantilever beam The cantilever beam 4 is fixed on the cantilever beam support frame 2, and the cantilever beam 4 passes through the through hole on the gap position adjustment frame 9, and is fixed on the gap position adjustment frame 9. The beam 10 is in a substantially parallel position; the gap head 6 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com