A Non-Complementary Flyback Active Clamp Converter

A non-complementary, converter technology, applied in the direction of converting DC power input to DC power output, instruments, and adjusting electrical variables, etc. It can solve the problems that the clamp switch Sa cannot realize soft switching, cannot release energy, and has large turn-on loss. , to achieve the effect of reducing circuit efficiency, increasing on-state loss, and reducing high-frequency oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

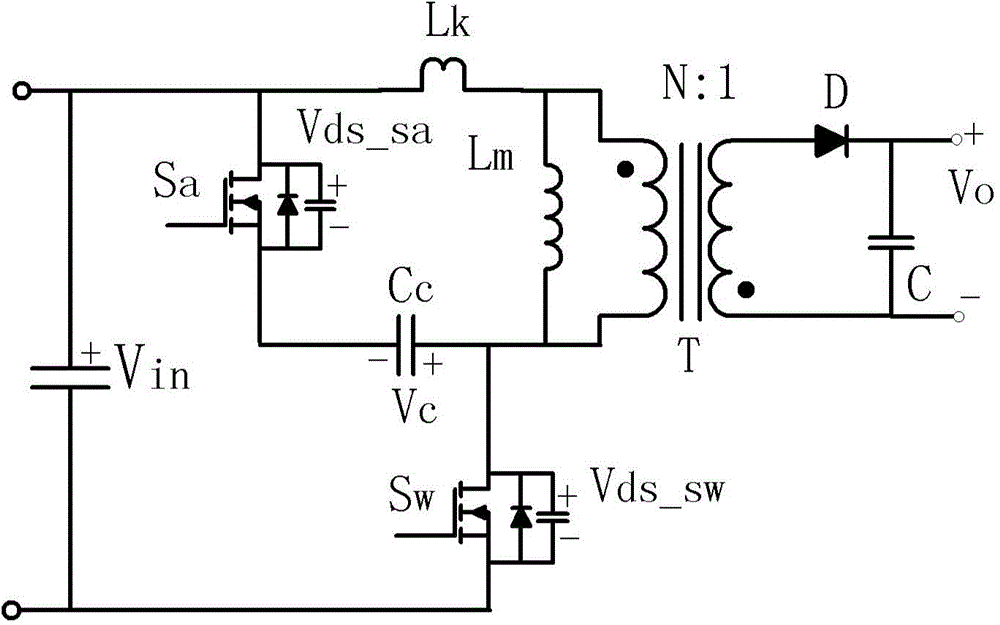

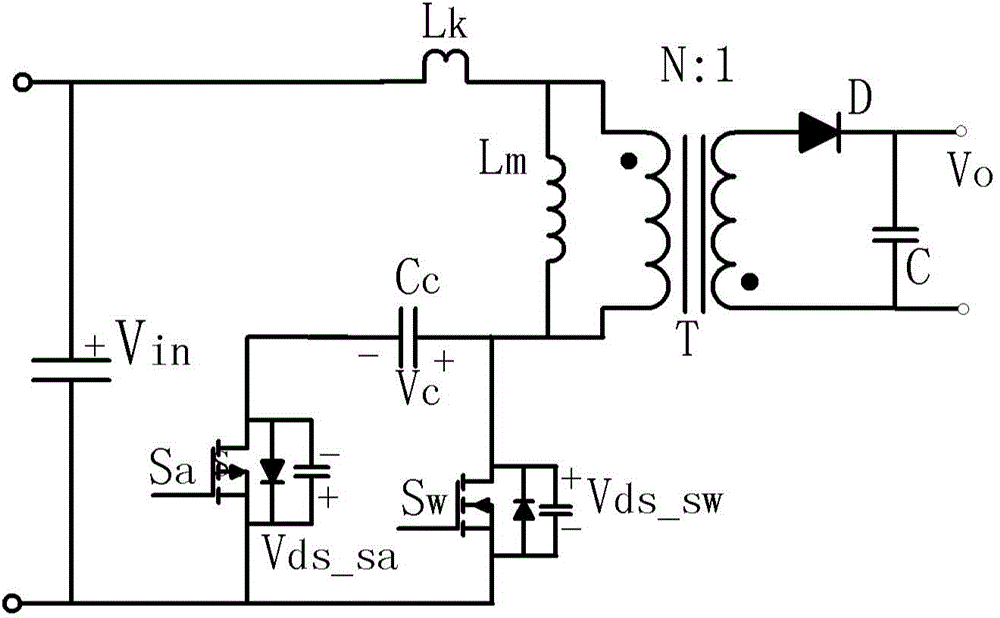

Embodiment 1

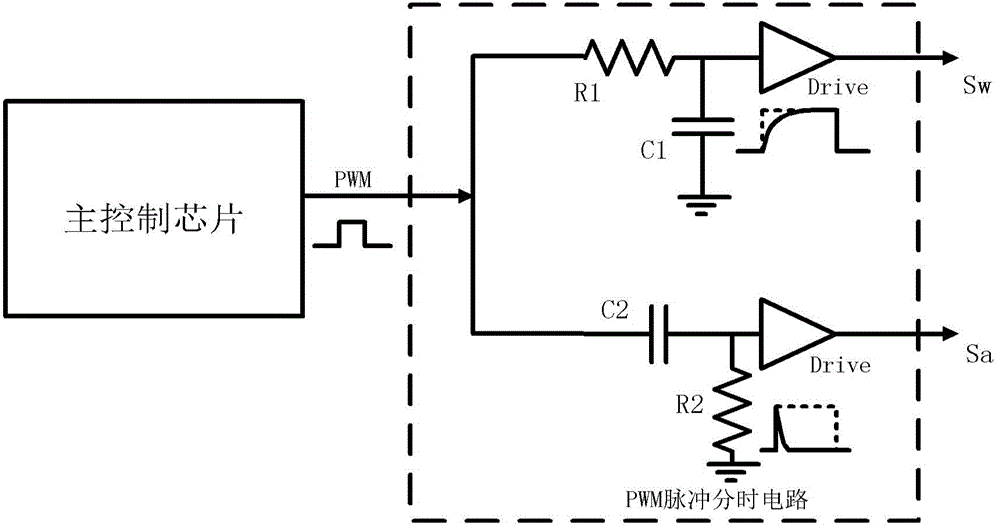

[0046] Such as Figure 7-1 As shown, the non-complementary flyback active clamp converter of Embodiment 1 of the present invention includes a transformer T, a main switch tube Sw, a clamp switch tube Sa, a clamp capacitor Cc, a drive module and an isolated drive circuit. The primary winding and the main switching tube Sw are connected in series for the input voltage signal, the secondary winding of the transformer T is used for outputting the transformed voltage signal, and the clamping switching tube Sa is an NMOS tube, which is connected in series with the clamping capacitor Cc to the transformer The primary windings of T are connected in parallel. The driving module outputs the main driving signal Vgs_sw for controlling the main switching tube Sw to be turned on and off alternately to the driving end of the main switching tube Sw, and the driving module outputs the clamping driving signal Vgs_sa to the driving end of the clamping switching tube Sa, The clamp drive signal V...

Embodiment 2

[0062] Such as Figure 9 As shown, the non-complementary flyback active clamp converter of the second embodiment of the present invention is basically the same as the first embodiment, and their difference is that in the second embodiment, the driving module includes a main control circuit and a second control detection circuit, They can be integrated in one chip.

[0063] see Figure 10 The main control circuit of the second embodiment includes a clock oscillation generator OSC, a second pulse signal module NarrowPulse2 for forming a second pulse signal Vgs_sa2, a second delay circuit Delay2, a logic circuit Logic, a ramp circuit Slope and a drive circuit Drive , the second control detection circuit includes a third delay circuit Delay3 and a first pulse signal module NarrowPulse1; the output terminal of the clock oscillation generator OSC is connected to the input terminal of the second pulse signal module NarrowPulse2, and the other is connected to the second delay The in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com