Component mounting device and component mounting method

A technology for installing equipment and components, applied in the field of component installation equipment and component installation, can solve the problems of heavy work load, difficult installation work for operators, and heavy work load for operators, so as to improve production efficiency, reduce work burden, and achieve efficient installation. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

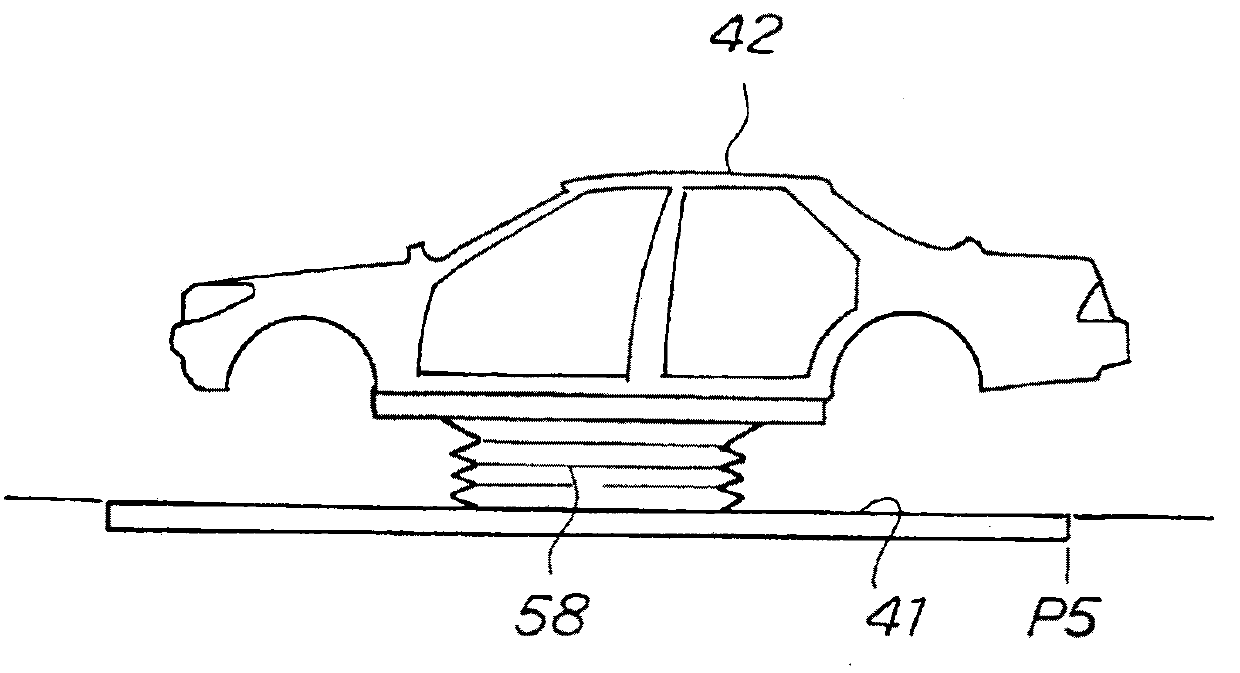

[0042] Although one or more operators 61 may be loaded on the workpiece transfer trolley 41 depending on the type of workpiece 42, in figure 1 , figure 2 In FIG. 2 , for ease of understanding, it is shown that one worker 61 is mounted on the work conveyance cart 41 . In addition, although the operator 61 is mounted on each workpiece transport trolley 41, the figure 1 , figure 2 A state in which an operator 61 is mounted on the selected workpiece transport cart 41 is shown in .

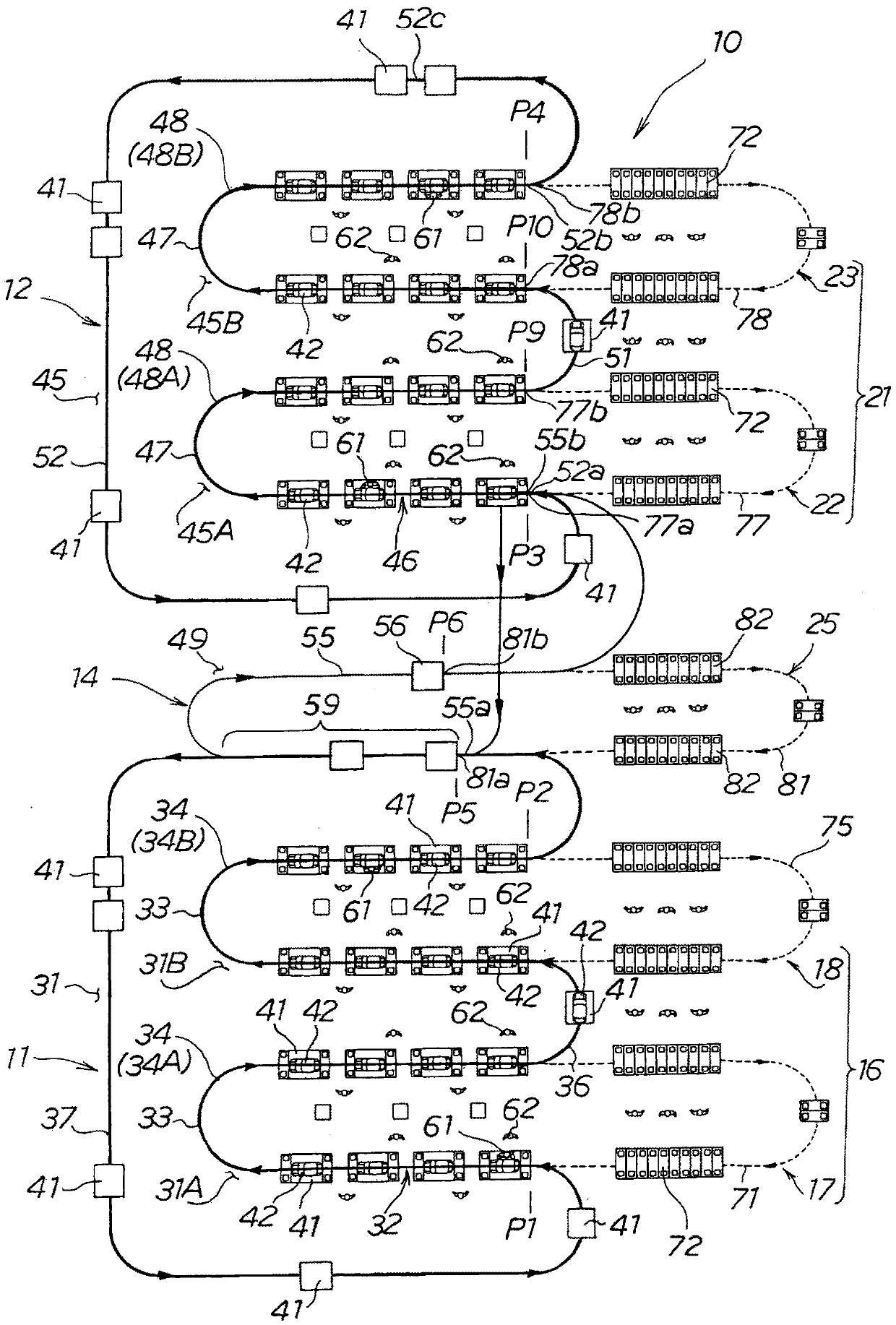

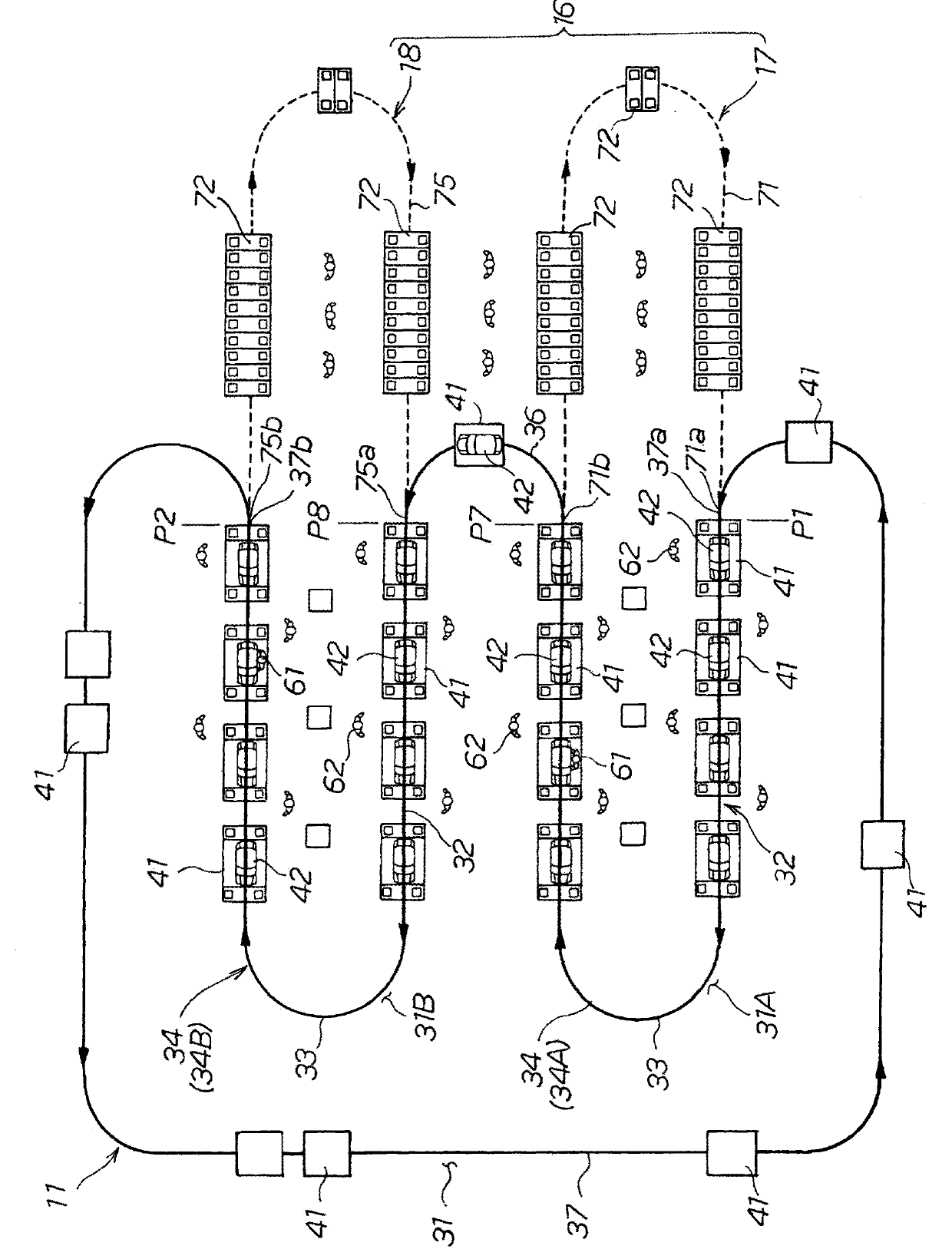

[0043] refer to figure 1 , the component mounting facility 10 includes: a first component mounting facility 11 provided on the upstream side, a second component mounting facility 12 provided on the downstream side of the first component mounting facility 11, a second component mounting facility 12 provided at the first component mounting facility 11 and a second component The lifting and conveying mechanism 14 between the installation equipment 12 is installed.

[0044] In addition, the componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com