Cylinder liner seal arrangement and method of providing the same

A cylinder liner and sealing device technology, which is applied to the sealing device, cylinder, cylinder head, etc. of the engine, and can solve the problem of damage to the seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

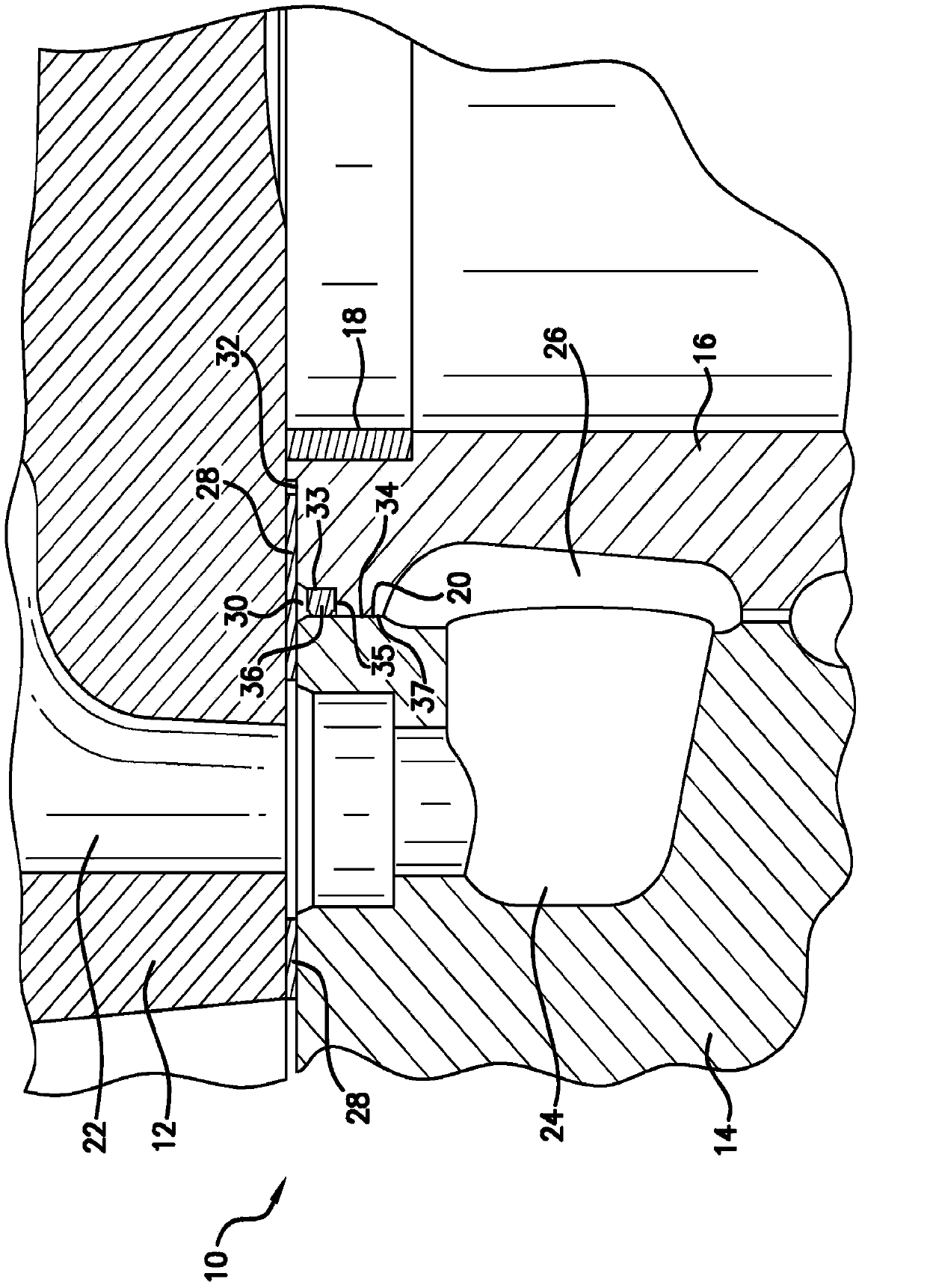

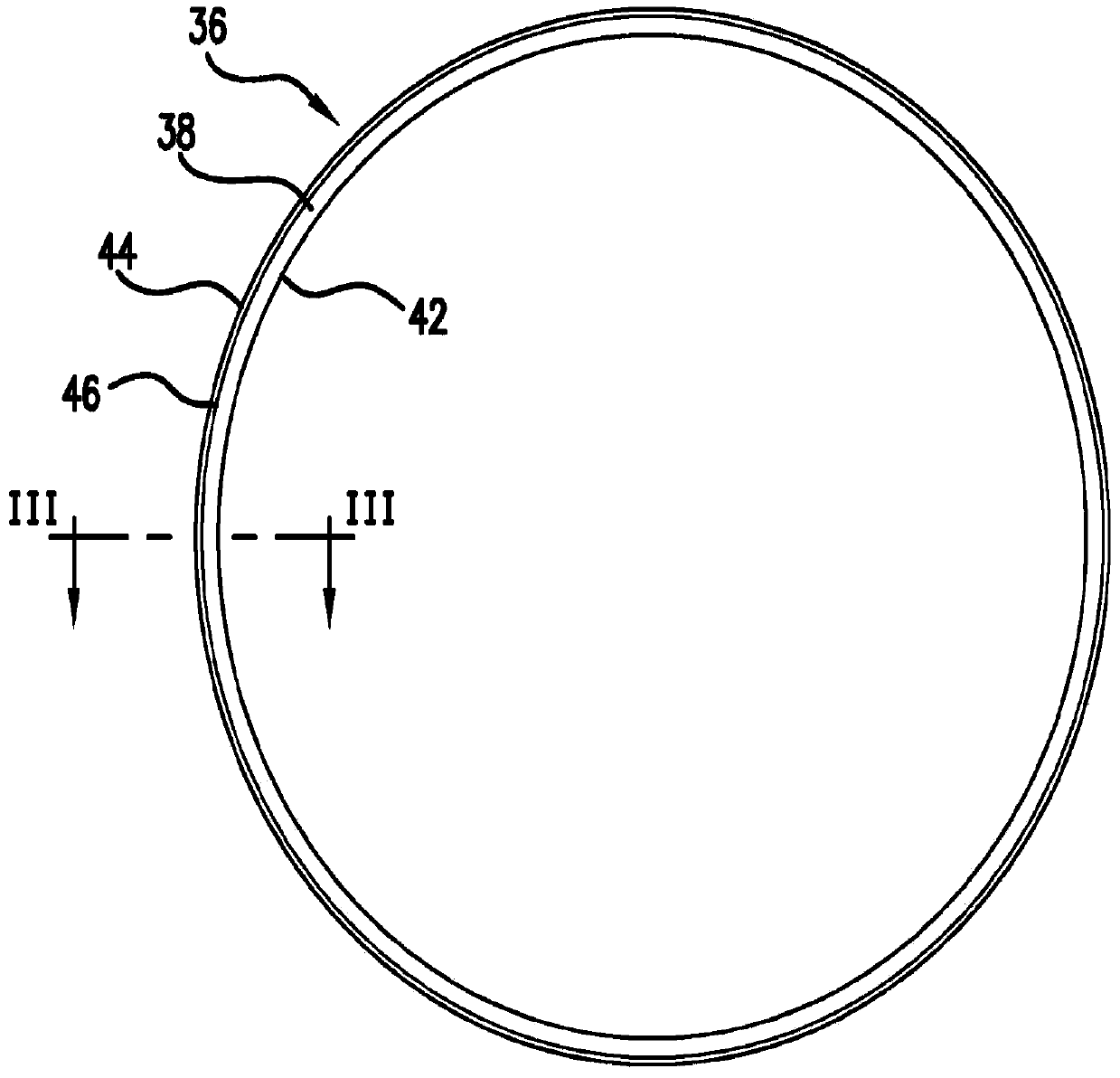

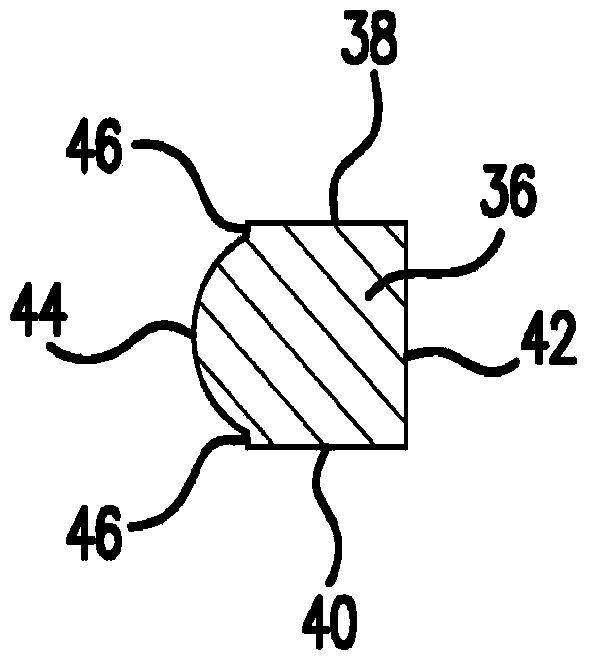

[0028] As mentioned above, seals are often provided between the respective cylinder liners and the cylinder block in order to keep the liner coolant provided between the cylinder liners and the cylinder block to pass between the cylinder liners and the cylinder block, And mixed with combustion gas. These seals are typically formed from an elastomeric material that may degrade over time to the point that it requires repair of one or more bushings disposed at the interface between the cylinder liner and cylinder block. Seals are replaced. In this case, the corresponding cylinder liner is removed, the worn or degraded liner seal is removed from the circumferential groove formed in the outer surface of the cylinder liner, and a new liner seal is positioned at each corresponding slots, and the cylinder liners are moved back and positioned in corresponding cylinder bores of the cylinder block. The inventors of the present invention point out that such a process is cumbersome and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com