Light-transmitting equipment and annealing equipment having said light-transmitting equipment

A technology of annealing equipment and equipment, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as breakage of transmission windows, and achieve the effects of preventing breakage, saving costs, and increasing replacement cycles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Now, embodiments according to the present invention will be described in detail with reference to the accompanying drawings. However, the present invention is not limited to the embodiments described below, but it can be embodied in various configurations. This embodiment is provided for sufficient understanding of the present invention, and the scope of the present invention can be fully understood by those of ordinary skill in the art by referring to this embodiment. In the drawings, like numerals indicate like elements.

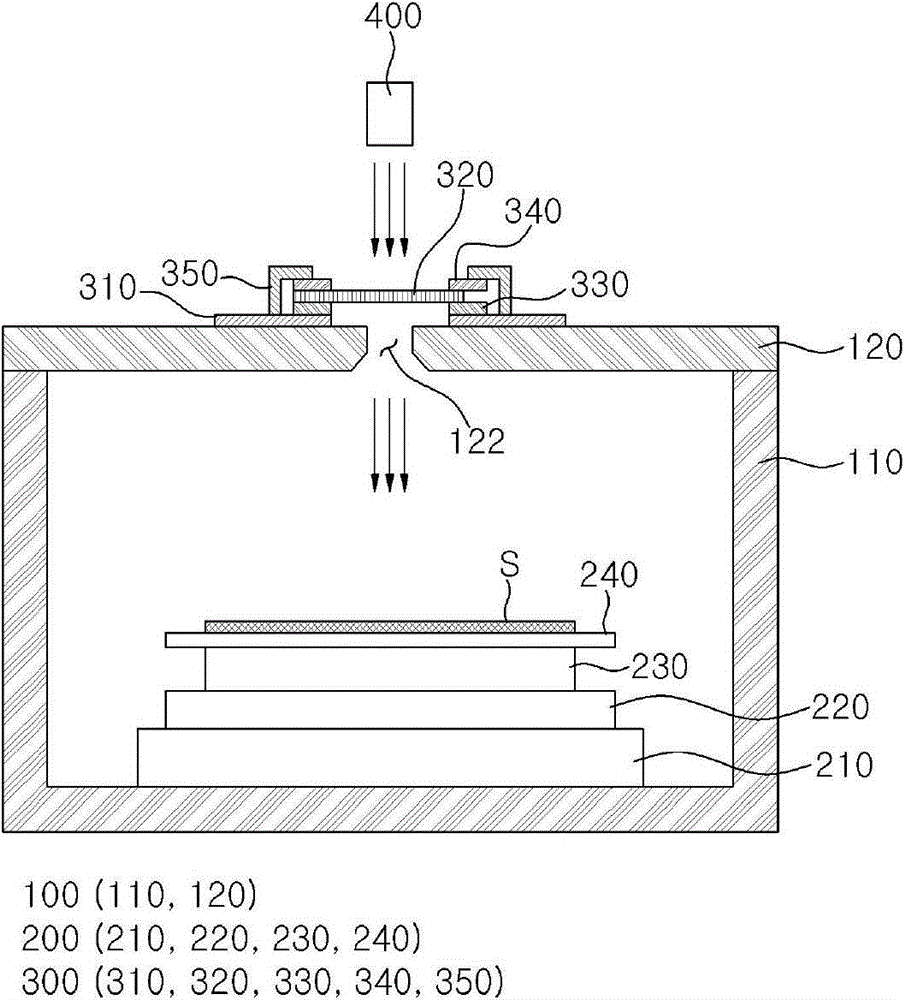

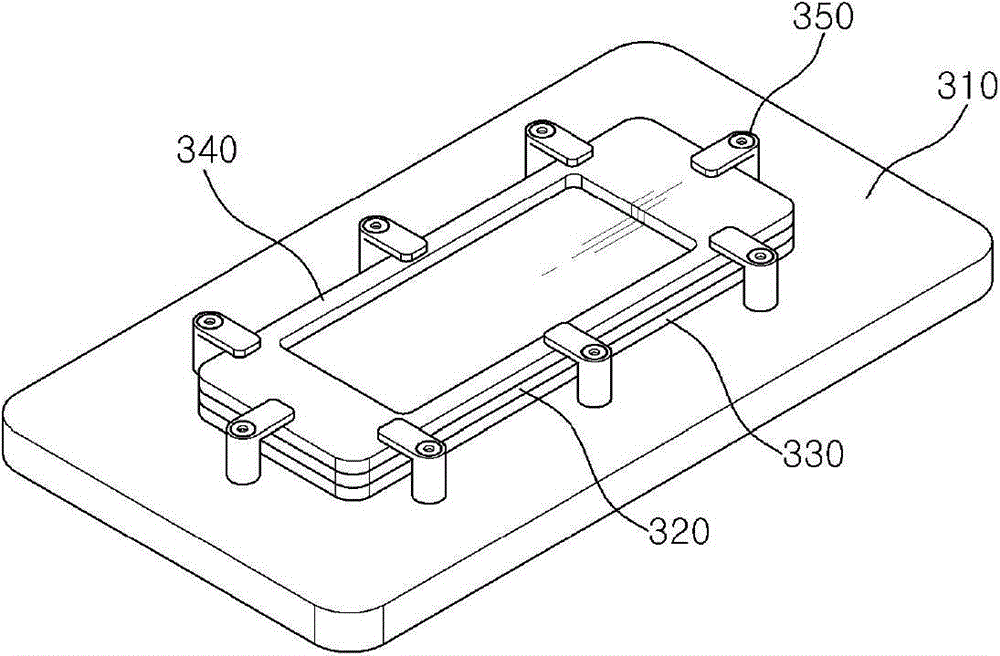

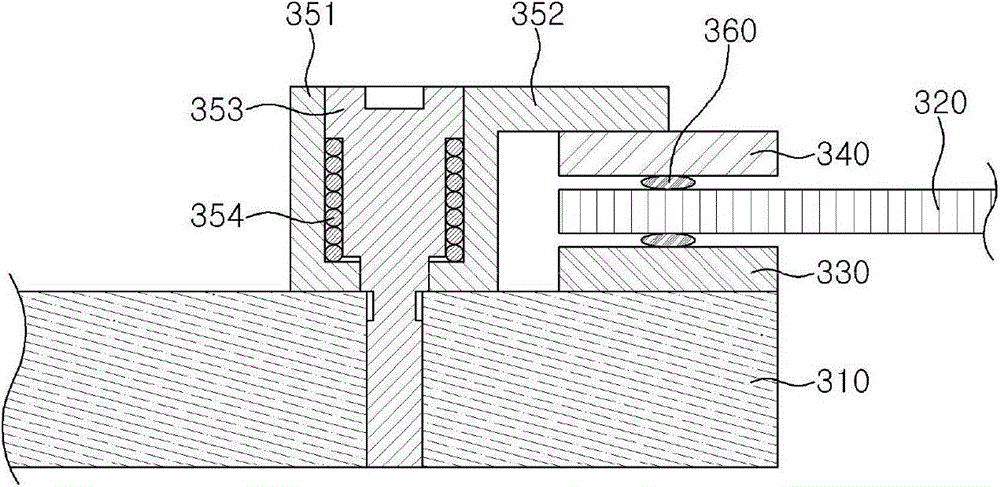

[0051] figure 1 is a schematic diagram showing a laser annealing device according to an embodiment of the present invention. and, figure 2 To show a schematic perspective view of a light-transmitting unit according to an embodiment of the present invention, image 3 is a partial cross-sectional view showing the light-transmitting unit, and Figure 4 is an exploded perspective view showing the light transmission unit with detached clamps. Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com