An assembled base

An assembled and connecting device technology, which is applied in the direction of thin plate connection, connecting components, workbench, etc., can solve the problems of occupying extra space, wasting resources, inconvenient use, etc., and achieve the effect of ensuring stability, simple structure, and easy manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

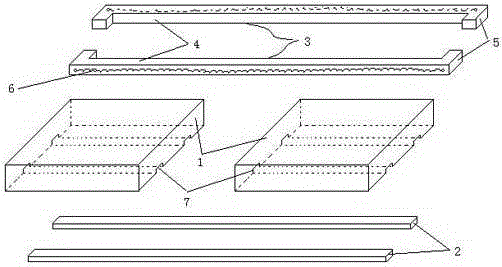

[0015] like figure 1 As shown, an assembled base includes a base unit 1 and a connecting device for connecting the base units 1. According to the size of the product, each base unit 1 is connected through the connecting device, which facilitates the production process and is flexible and convenient to use. , Promote the production speed and improve the production efficiency. In detail, the bottom of the base unit 1 is provided with several grooves 7 arranged side by side. The design of the grooves 7 will not affect the use of a single base unit 1, and can facilitate the subsequent connection of the base units 1. The grooves 7 are arranged side by side, the shape is regular and the stability of the base unit 1 is ensured, preferably two grooves 7 are evenly distributed on the bottom of the base unit 1, and the number of grooves 7 can be determined according to the over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com