Flexible combined steel sleeper

A combined, steel rail technology, applied in the direction of tracks, roads, ballast layers, etc., can solve the problems of inconvenient transportation and storage, high maintenance costs, and inability to recycle. It is beneficial to production organization, reduce transportation costs, and appearance Color highlighting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

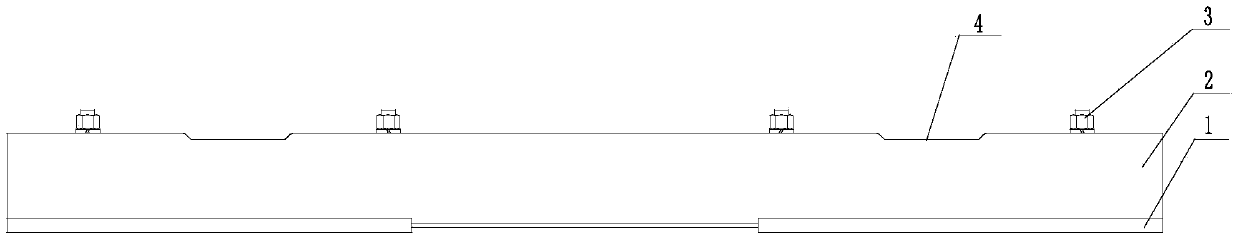

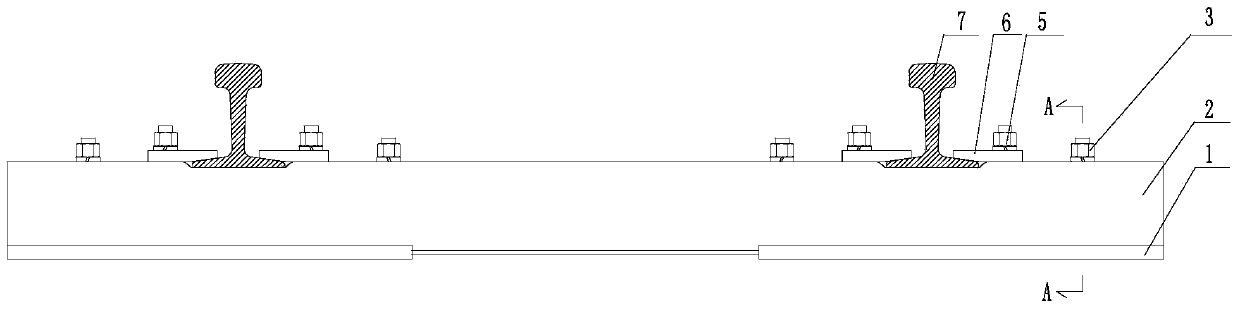

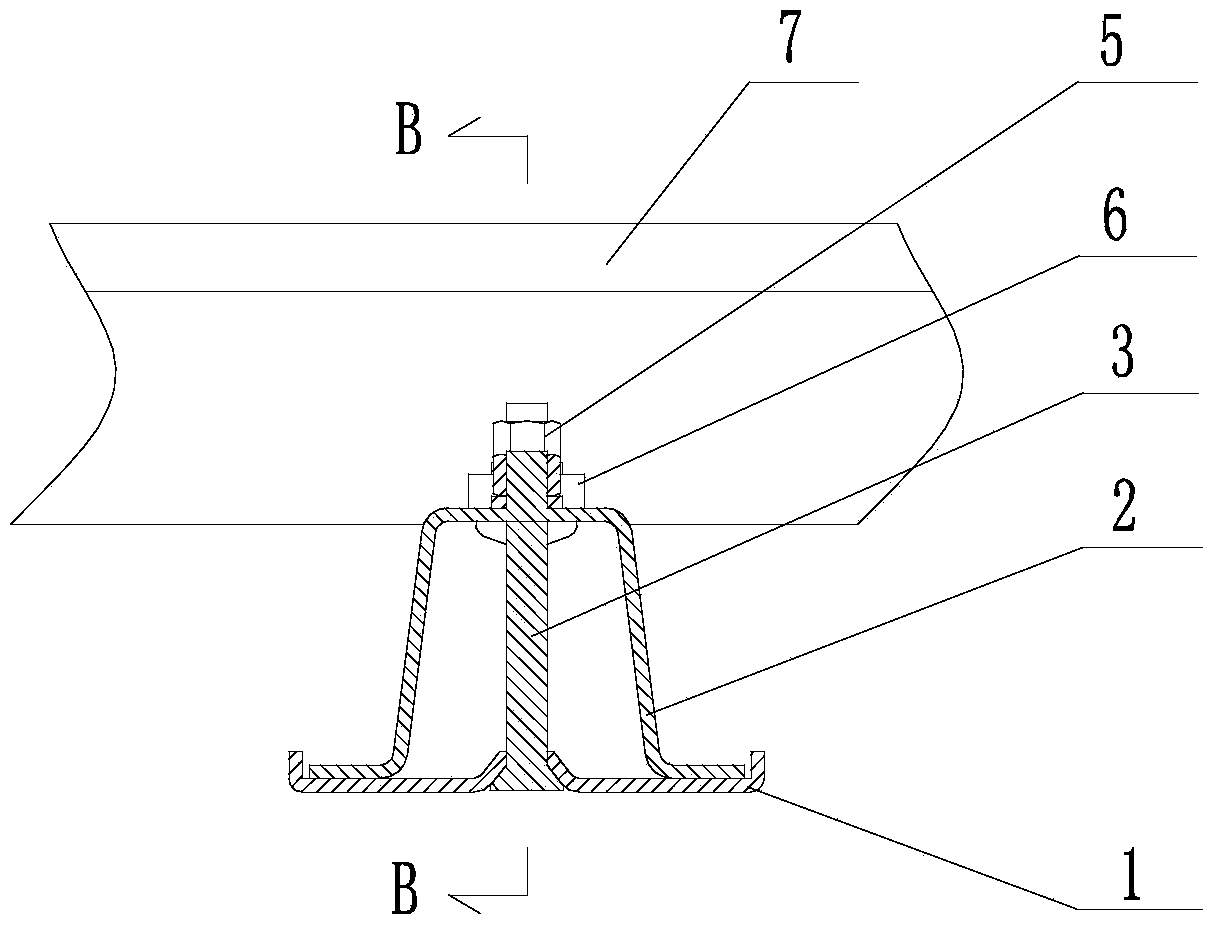

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a flexible combined steel sleeper, the sleeper 2 is stuck on the slot-shaped backing plate 1, and the sleeper 2 is fixed on the slot-shaped backing plate 1 by fastening bolts 3 to form a whole sleeper; on the sleeper 2 A fixed bayonet 4 for the gauge is provided, and the sleeper 2 is formed by pressing a steel plate with a trapezoidal cross section.

[0015] Fix the groove-shaped backing plate 1 on the flat concrete ground first, then install the sleeper 2 into the groove-shaped backing plate 1, fasten the bolts 3 to fix the sleeper 2 on the groove-shaped backing plate 1, so as to realize the connection between the sleeper 2 and the groove-shaped backing plate 1. The amount of elastic deformation between the slot-shaped backing plates 1 is adjusted; the sleeper 2 is molded by a whole piece of steel plate at one time, and its structural shape and size are standard, and the structural bearing capacity is str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com