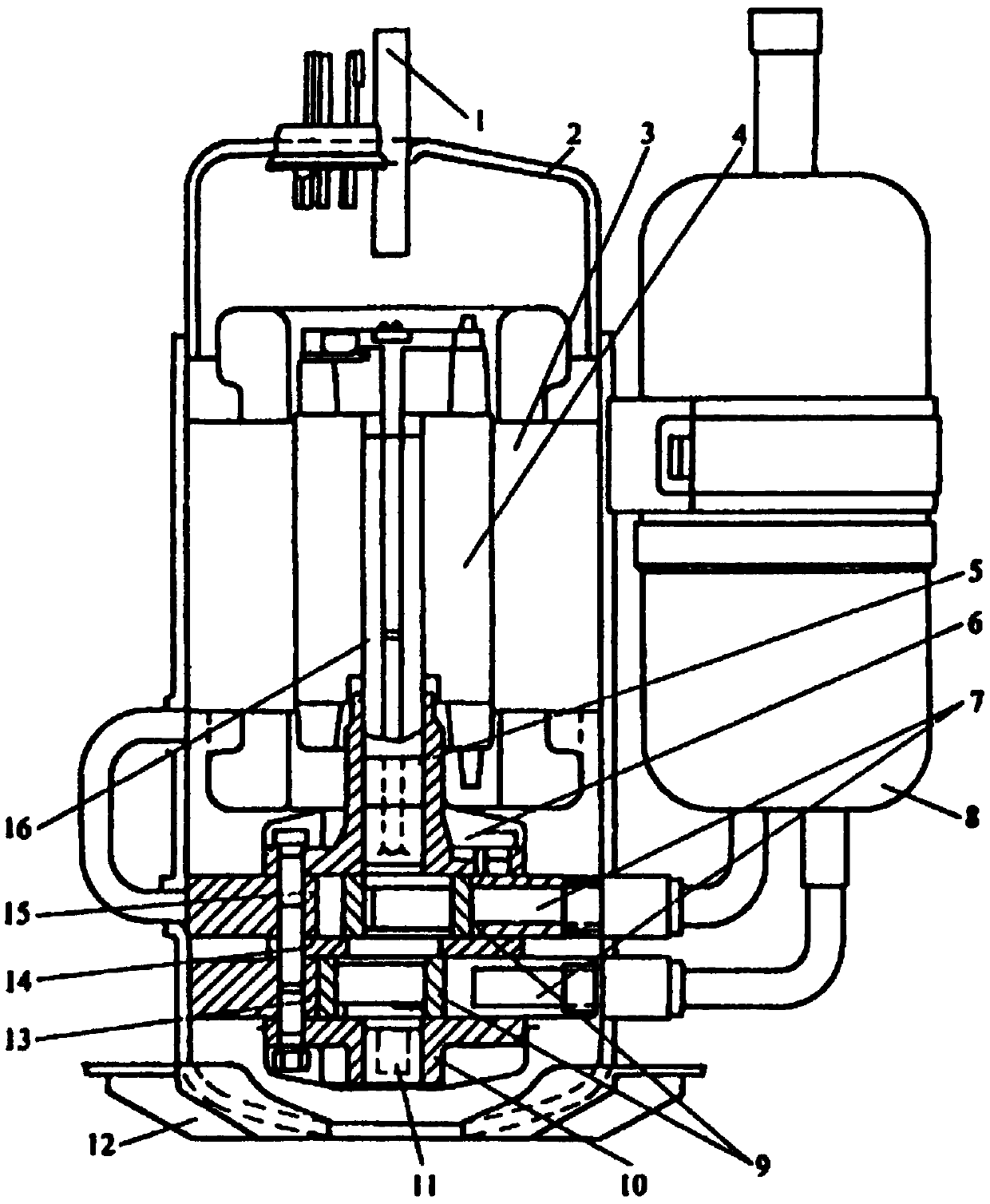

Three-cylindrical rolling rotor type compressor

A rolling rotor type, compressor technology, applied in the field of refrigeration compressors, can solve problems such as inability to fit in, crankshaft eccentric shaft components are not produced, and achieve the effects of rotational balance, low vibration and noise, and balanced overall load torque.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

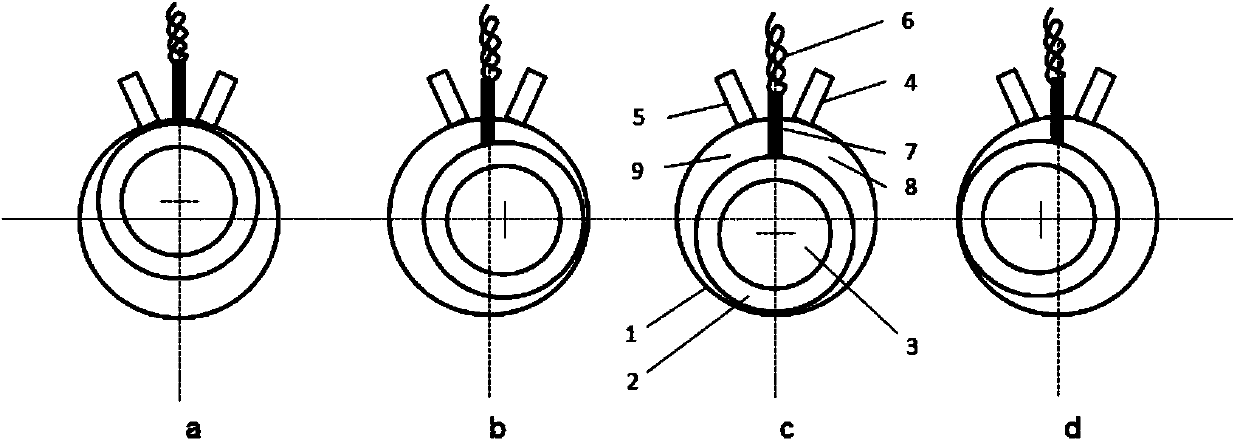

[0037] like Figure 4 , the angular arrangement of the three cylinders used in the present invention is not evenly divided by 360°, wherein the sliding vanes (4, 5) of two adjacent cylinders (1, 2) are arranged at an angle staggered by 120°, and the third cylinder 3 The slide plate 6 and the front two cylinders are respectively staggered by 60°.

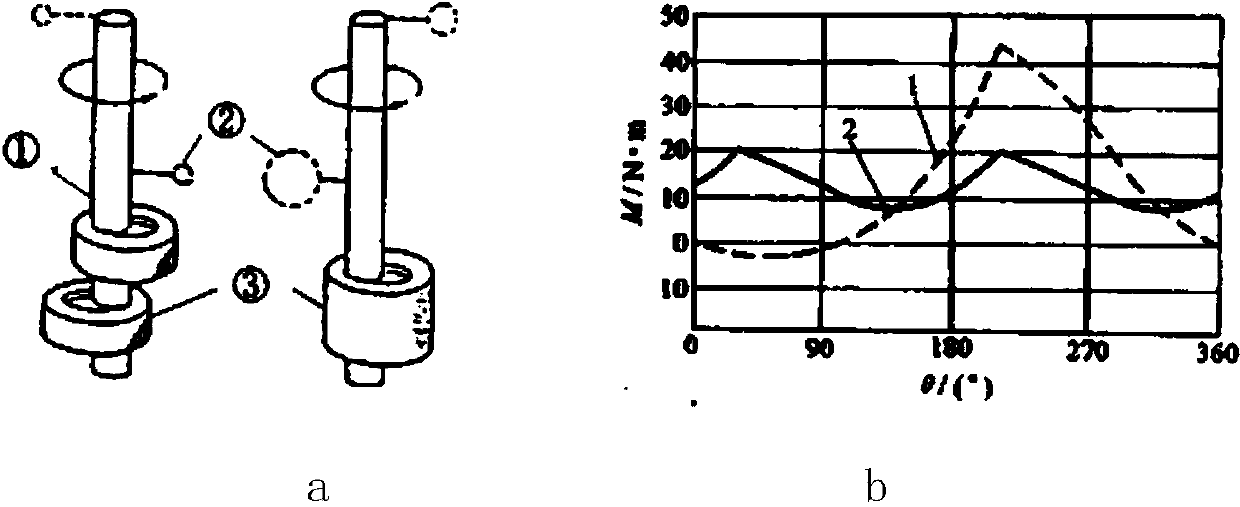

[0038] like Figure 5 a, The crankshaft 1 and eccentric shafts (2, 3, 4) used in the present invention are integrally processed, and the eccentric directions of two adjacent eccentric shafts (2, 3) are exactly the same. The eccentric direction of the third eccentric shaft 4 is designed to be staggered by 180° from the two eccentric shafts with the same eccentric direction.

[0039] like Figure 5 a, Two eccentric shafts (2, 3) with exactly the same eccentric direction can be designed to be closer to the crankshaft 1 insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com