Method and device for sealing a machine part relative to a second machine part

A technology of machine parts, seals, applied in the field of sealing machine parts and devices relative to a second machine part, capable of solving problems such as no seal wear optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In the following, preferred embodiments will be described based on the drawings. In this case, identical, similar or identically acting elements are provided with the same reference symbols in the different figures and some of these elements are not described repeatedly in the following description in order to avoid complexity.

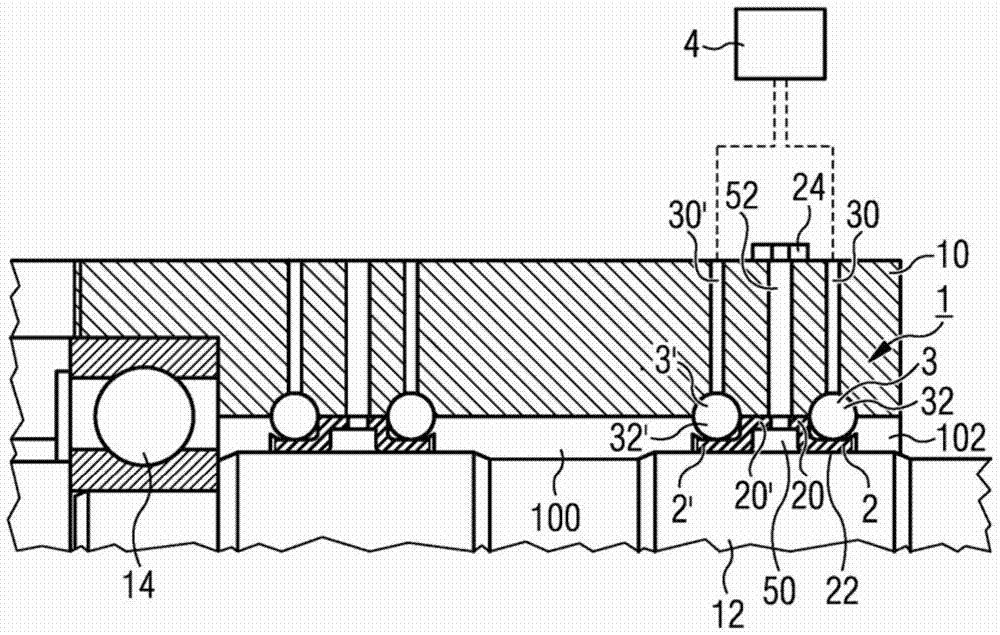

[0036] exist figure 1 A device 1 for sealing a first machine part 10 relative to a second machine part 12 is shown in figure 1 The first machine part 10 is a housing and the second machine part 12 is a shaft mounted in the housing, for example supported in the housing via schematically shown bearings 14 . Such an arrangement can be used, for example, in rotary media dispensers in beverage filling plants.

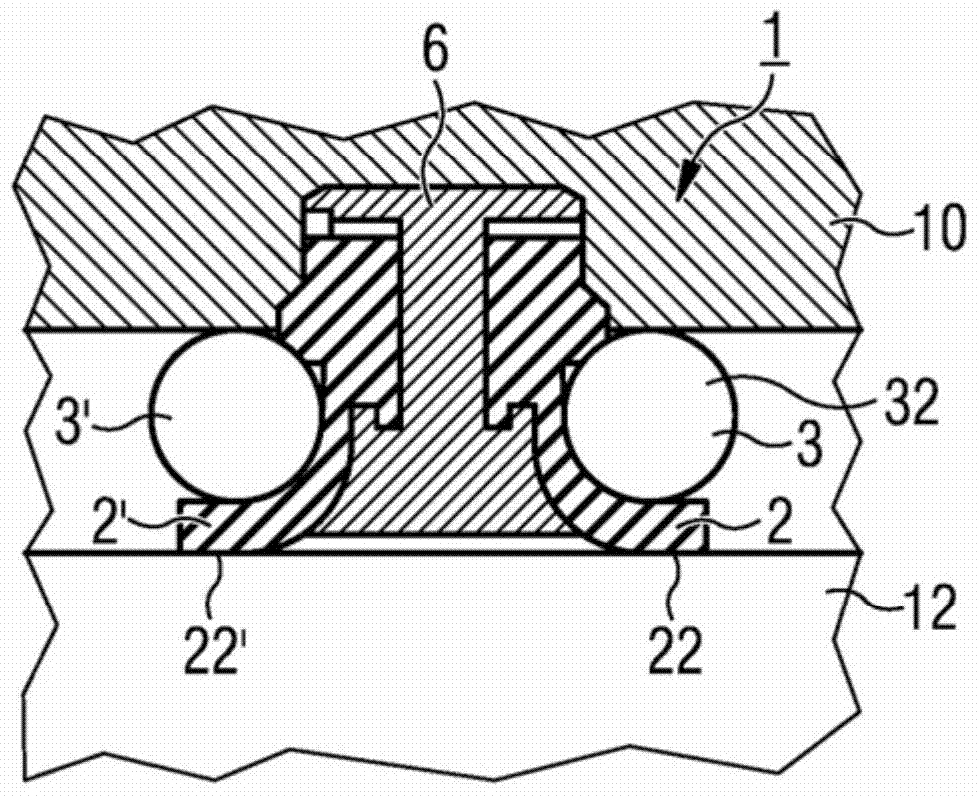

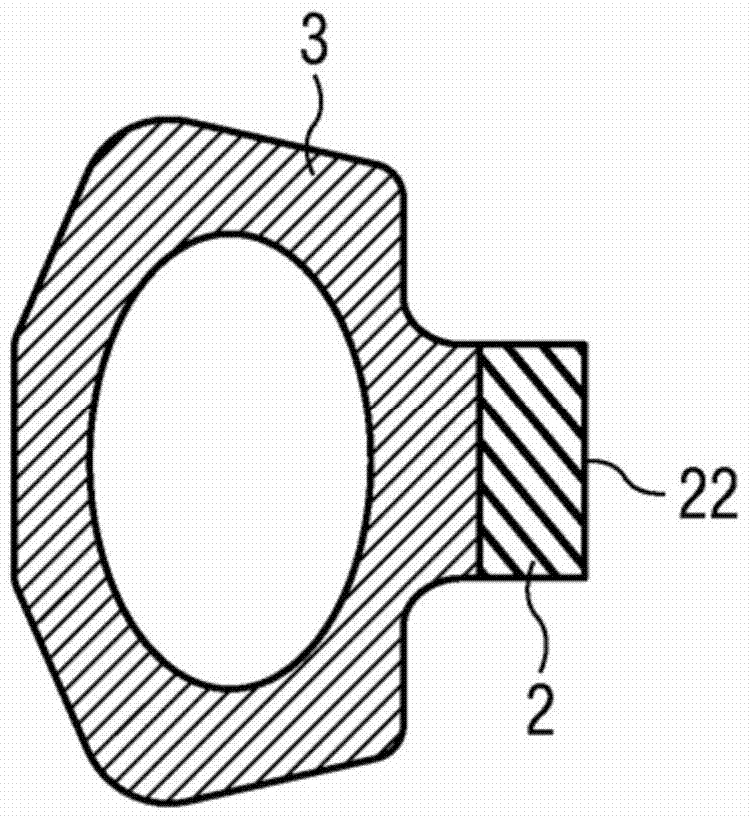

[0037] The seal 2 is shown, which is held on the first machine part 10 in the holding area 20 of the seal 2 and which bears sealingly against the second machine part 22 in the contact area 22 of the seal 2 . part 12. A fluid-operable pret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com