Intelligent cement loading and unloading monitoring system for wharf

A monitoring system and wharf technology, applied in the field of intelligent control of wharf loading and unloading ships, can solve the problems of safety, low ship loading efficiency, lack of monitoring and automatic control, etc., and achieve the effect of reliable information transmission and fast communication speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and extended understanding of the inventive concepts and technical solutions of the present invention.

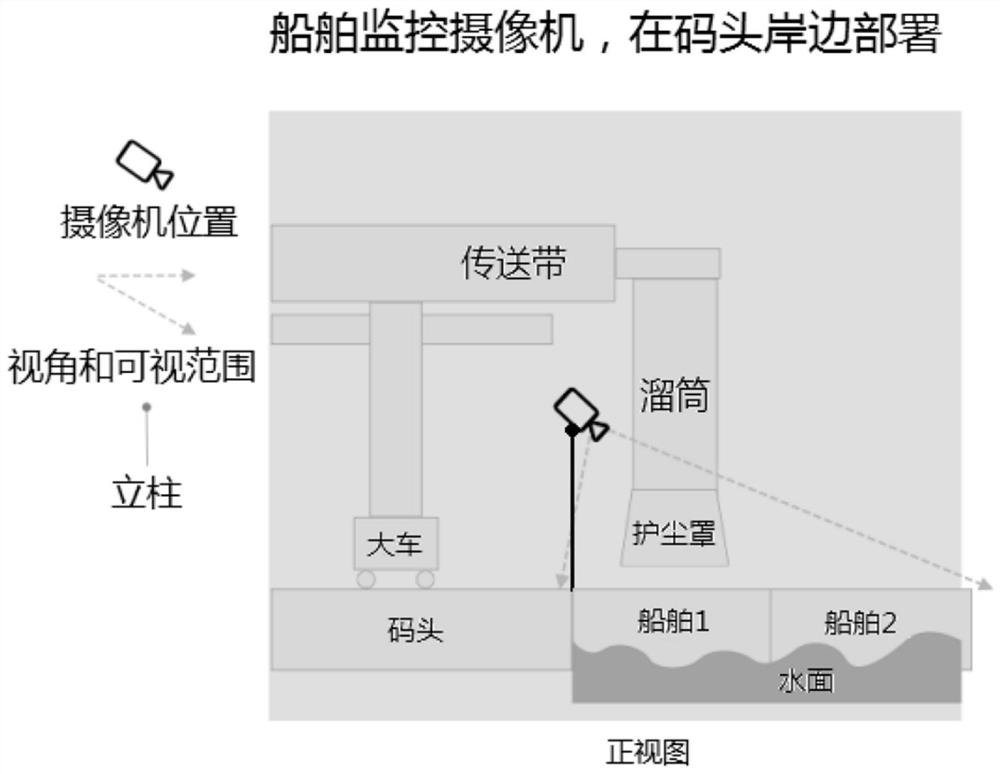

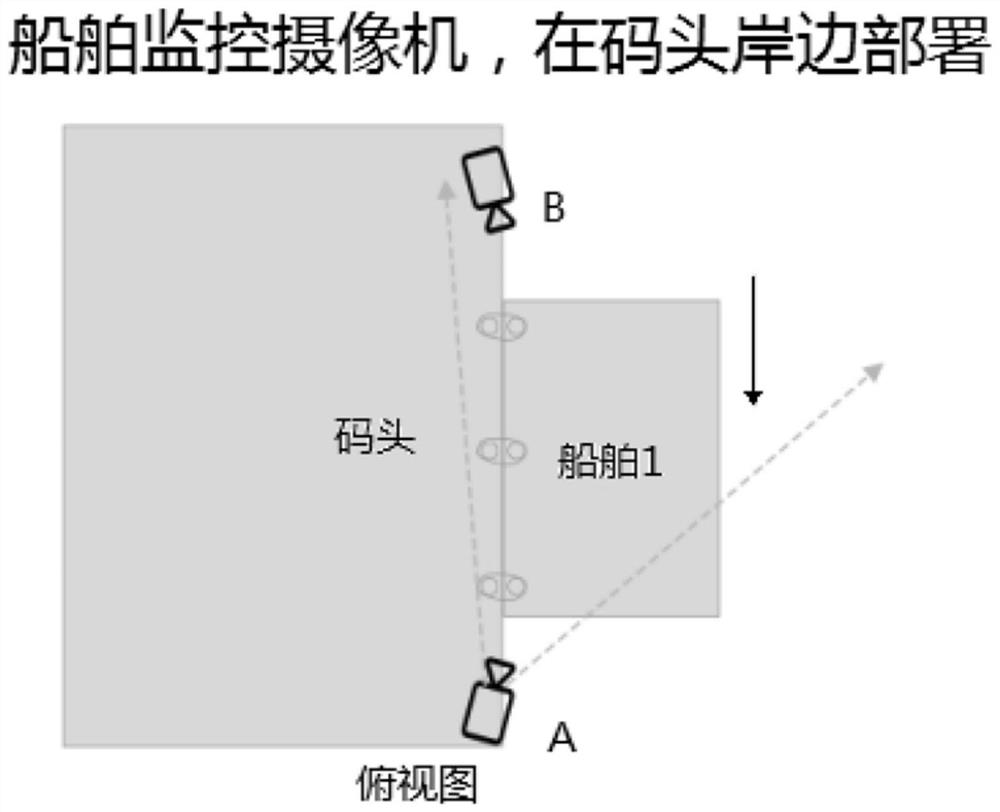

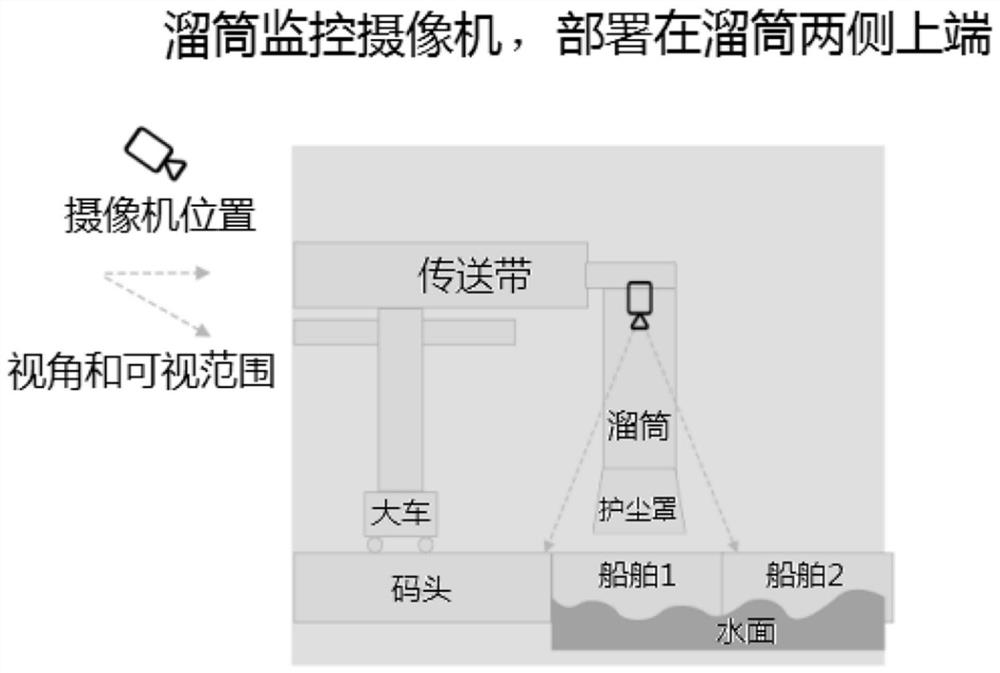

[0034] Such as Figure 1-11As shown, the present invention provides a wharf intelligent cement loading and unloading monitoring system, including a ship loader and a central control room, the ship loader communicates with the central control room through a 5G virtual private network, and the ship loader is provided with an upright slide A pair of chute monitoring cameras are arranged symmetrically on the upper ends of both sides of the chute, and the chute monitoring cameras shoot vertically downwards and the shooting direction is aligned with the central axis of the discharge port of the chute. Two ship monitoring cameras are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com