MEMS (micro-electromechanical system) three-axis gyroscope error calibration method

An error calibration and gyroscope technology, applied in the field of testing, can solve the problems of low calibration angle, large amount of calculation, complex model establishment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

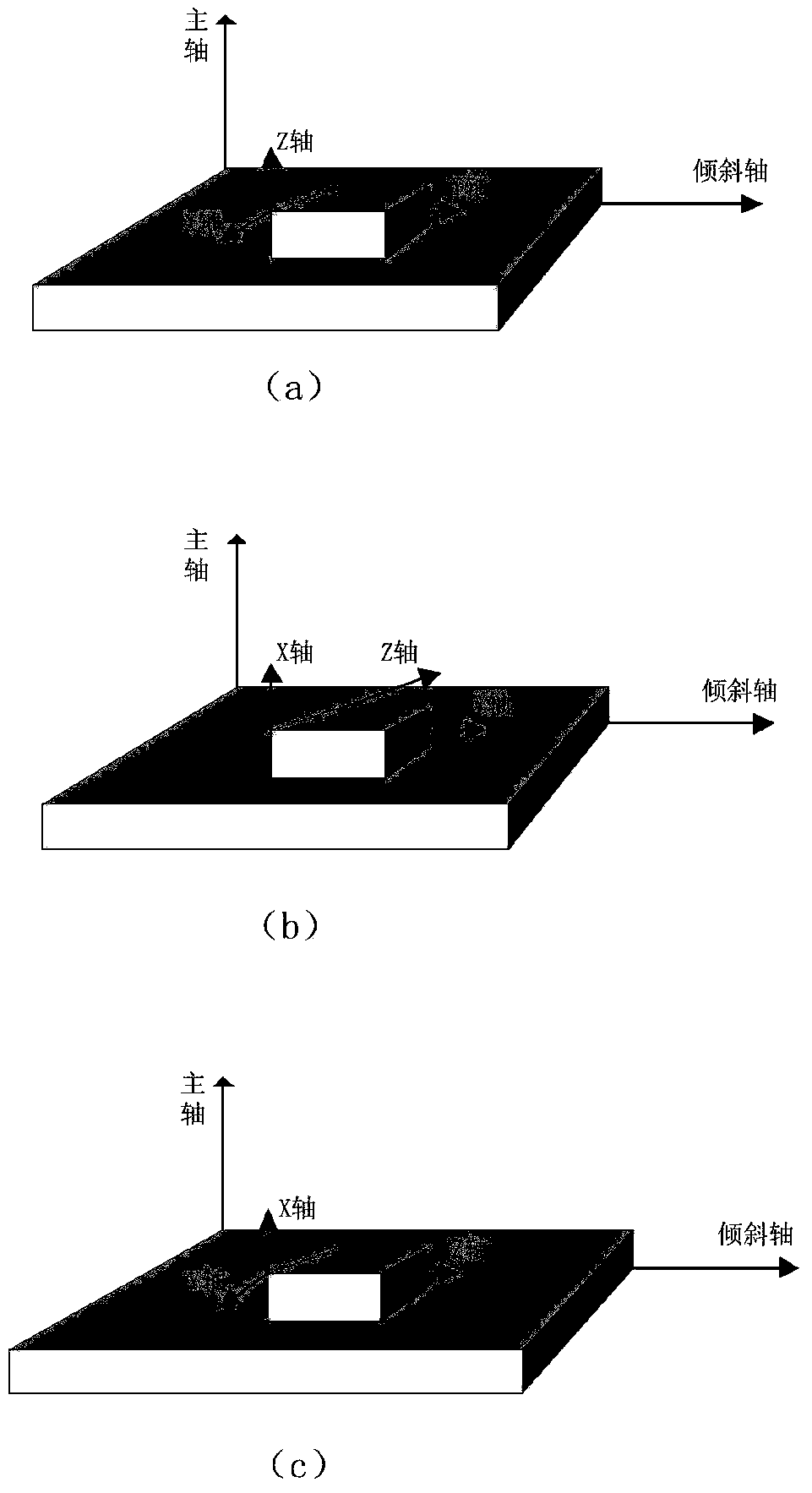

[0034] The present invention will be described in detail below with reference to the accompanying drawings and examples.

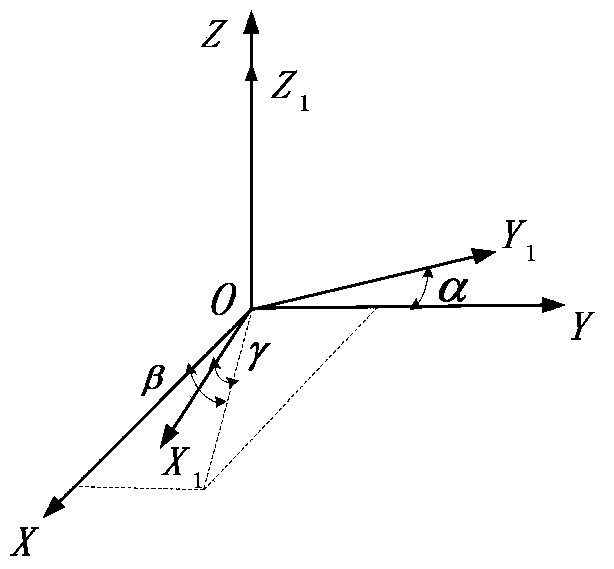

[0035] (1) Establish the error correction model of the MEMS three-axis gyroscope. The errors of the MEMS gyroscope are mainly manifested as fixed constant error, scale factor error and non-orthogonal error of the installation axis of the gyroscope. The constant value error is due to the error caused by the sensor, the analog circuit and the zero point of the A / D conversion not being zero, and the error caused by the data offset. The scale factor error is the error caused by the inconsistency between the scale factor in the actual working environment and the preset scale factor.

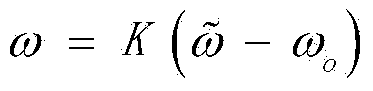

[0036] fixed constant error ω 0 = ω x 0 ω...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com